T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

Q: I need high-purity, high temperature resistant, and accurately sized quartz plates, but the standard products on the market cannot meet my special process requirements. What should I do?

A: Choose a professional quartz product factory with full process customization capabilities to tailor high-precision quartz plates according to your drawings, specifications, and application scenarios, solving core pain points such as insufficient temperature resistance, size discrepancies, and purity non-compliance.

Quartz material has become the preferred material for key components in the global semiconductor, photovoltaic, optical, laboratory equipment, and high-end manufacturing industries due to its excellent thermal stability, chemical inertness, high transparency, and low thermal expansion coefficient. However, standard size or universal quartz plates often struggle to match customers' specific process requirements. As a manufacturing enterprise that has been deeply involved in the field of quartz products for many years, we focus on providing high-purity, high-precision, and fully customized quartz plate processing and production services to global customers.

Product application areas

Customized quartz plates are widely used in various high-tech and industrial fields due to their excellent physical and chemical properties

-Semiconductor and electronics industry: used for wafer carrier, etching mask, lithography machine components, etc., with high temperature resistance and high purity characteristics to ensure production stability.

-In the field of optics and optoelectronics, as a UV transmission window, laser device substrate, and optical lens material, it has low thermal expansion coefficient and high transmittance.

-Laboratory and medical equipment: used for high-temperature reaction vessels, laboratory carriers, medical analytical instrument components, corrosion-resistant and easy to clean.

-Industrial high-temperature environment: As a furnace window, heat treatment tray, and high-temperature insulation plate, it can maintain structural integrity under long-term high temperature.

-New energy and photovoltaic industry: used as load-bearing and protective components in the manufacturing process of solar cells, with strong weather resistance and stable performance.

Core advantages of the product

1. High purity material: Selected high-purity quartz sand with SiO ₂ content ≥ 99.9% is used to ensure low bubbles, low impurities, and reliable performance.

2. Precision machining capability: Equipped with CNC cutting, precision grinding, drilling, etching and other technologies, the tolerance can be controlled within ± 0.1mm.

3. Excellent physical properties: high temperature resistance (up to 1100 ℃ or above), low thermal expansion coefficient, high ultraviolet transmittance, excellent electrical insulation.

4. Customized surface treatment: Polishing, sanding, coating and other treatments can be provided to meet different needs for light transmission, anti reflection or friction resistance.

5. Strict quality inspection: Each batch of products undergoes tests for thickness uniformity, flatness, light transmittance, and temperature resistance, meeting international standards.

Customization service for specifications and dimensions

We support comprehensive and flexible customization to meet diverse needs:

-Size range: thickness 0.5mm-50mm, maximum size up to 1500 × 2000mm.

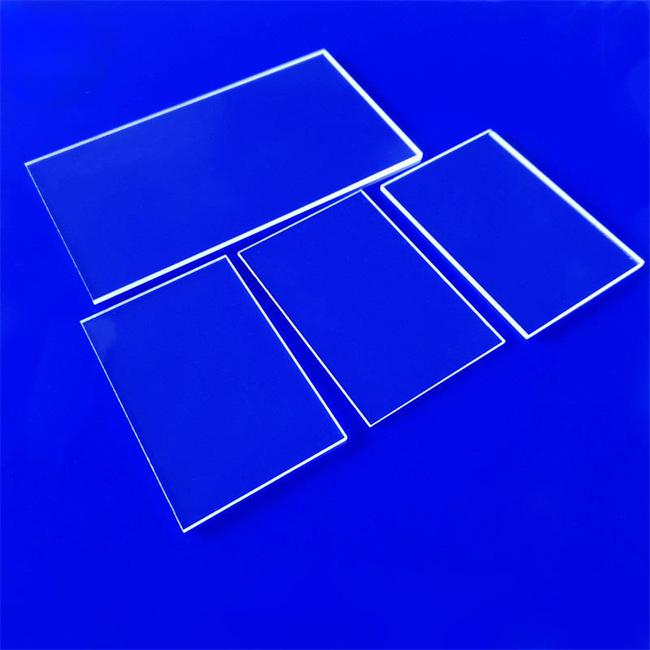

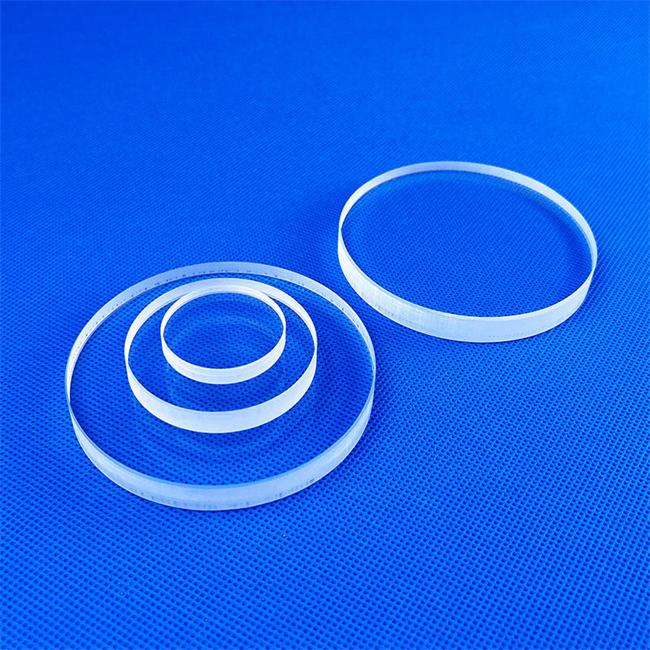

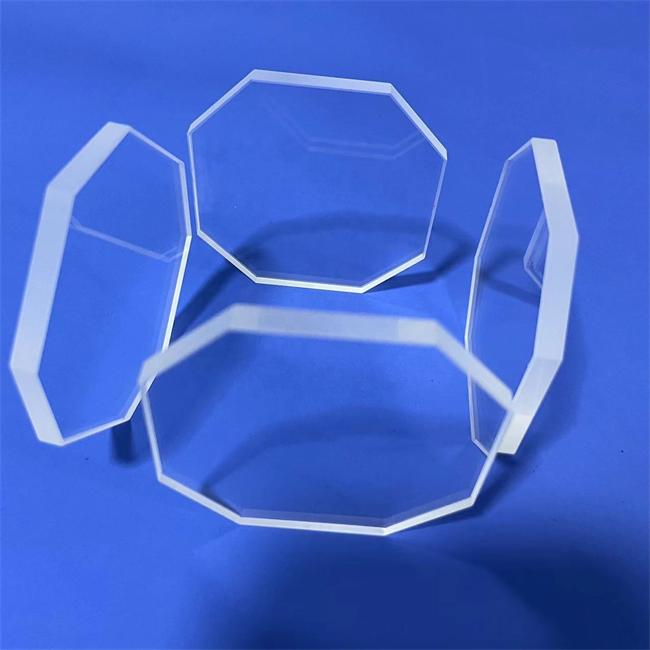

-Shape customization: Supports circular, rectangular, and irregular cutting, and can perform secondary processing such as chamfering, slotting, and drilling.

-Purity and Color: Provides different color options such as transparent, milky white, black, etc. The purity level can be adjusted as needed.

-Batch flexibility: supports customization of small batch samples to large-scale production, with short delivery cycles and rapid response.

What problems can we solve?

1. Limitations of alternative materials: Addressing issues such as glass fragility, metal corrosion, and plastic's inability to withstand high temperatures, providing more durable solutions.

2. Precision machining requirements: Meet high-precision size and complex shape requirements, reduce customer secondary machining costs.

3. High temperature and corrosive environment challenges: Provide material solutions that remain stable under extreme conditions.

4. Supply chain response efficiency: With mature foreign trade experience, we provide one-stop services from design consulting to logistics distribution, shortening the international procurement cycle.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

Application case (anonymous)

1. German optical company: Customized UV optical quartz window panels with a thickness of 3mm and a diameter of 200mm, coated with anti reflective film on the surface, for use in laser equipment, with a 15% increase in transmittance.

2. American semiconductor equipment manufacturer: Bulk supply of high-temperature load-bearing quartz plates with specifications of 500 × 600mm, temperature resistance of 1100 ℃, replacing the original ceramic materials, and extending the service life by three times.

3. Japanese laboratory instrument company: Customized corrosion-resistant microporous quartz plate for chemical analysis instruments, with a pore size accuracy of ± 0.05mm, greatly improving detection stability.

4. Middle Eastern photovoltaic manufacturer: Long term cooperative supply of quartz plates for solar cell lamination, strong weather resistance, suitable for high-speed production lines, with an annual supply of over 5000 pieces.

As your reliable global partner for quartz products, we adhere to the principle of technology support and customer centricity, providing full customization services from drawings to finished products. If you have quartz plate procurement or customization needs, please feel free to contact us at any time for sample and solution consultation - let us use professional manufacturing to help your project become more outstanding!

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.