T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-20 Origin: Site

Q: I need to customize a quartz plate, but standard products on the market cannot meet my special requirements. What should I do?

Answer: We can provide professional customization services to meet your personalized needs in terms of size, material, accuracy, and application scenarios, ensuring that the product fully matches your project requirements.

Q: My project has strict standards for the high temperature resistance, purity, or optical performance of quartz plates. How can I ensure quality?

Answer: We use high-purity quartz raw materials (SiO ₂ ≥ 99.9%), combined with precision processing technology, to ensure that our products have excellent thermal stability, low expansion coefficient, and customized performance, meeting the high-precision requirements of industrial, scientific research and other scenarios.

Q: I need small batch customization and the delivery cycle is tight. Can I respond quickly?

Answer: We support a flexible production mode from prototype to mass production, providing fast prototyping and flexible delivery services to help you efficiently advance project progress.

As a manufacturer specializing in customized quartz product production, we are committed to providing high-quality and high-precision quartz plate processing and customization services to global customers. With years of experience in quartz, we have successfully served purchasers and end-users in multiple countries and regions around the world, covering industries such as industry, research, semiconductors, optics, and healthcare. We can provide professional and reliable solutions for both standard specifications and complex customization needs.

Product application areas

Quartz plates are widely used in the following scenarios due to their excellent physical and chemical properties:

-Semiconductor and Electronics Industry: Used for wafer support, etching equipment observation windows, high-temperature process components, etc.

-Optics and Optoelectronics: As a UV lens, laser window, and optical substrate, it has high transmittance and high temperature resistance.

-Laboratory and research equipment: high-temperature reaction vessels, spectrometer components, precision measuring instrument components.

-Medical and Biotechnology: Medical equipment windows, sterilization trays, testing instrument components.

-Industrial manufacturing: high temperature observation window, corrosion-resistant lining plate, precision insulation material.

Product advantages and features

Our customized quartz plates have the following core advantages:

1. High purity material: using 99.99% or more high-purity quartz sand to ensure low bubbles, low impurities, and stable performance.

2. High temperature resistance and thermal stability: The softening point is as high as 1730 ℃, and the coefficient of thermal expansion is extremely low, making it suitable for extreme temperature environments.

3. Excellent corrosion resistance: resistant to most acids, alkalis, and organic solvents, suitable for harsh chemical environments.

4. High transparency: Both ultraviolet and infrared bands have good transparency, meeting the requirements of optical grade applications.

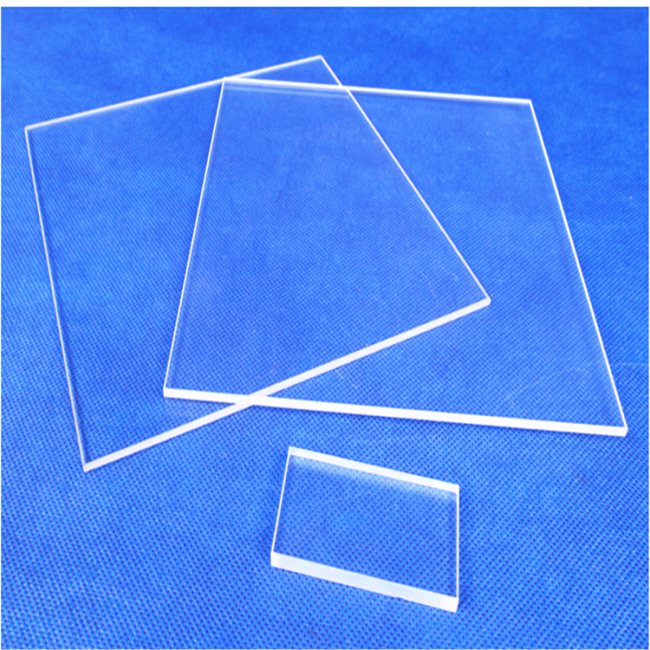

5. Precision machining capability: customizable thickness (0.5mm-150mm), size (maximum 1500mm × 800mm), surface polishing (rough grinding to optical grade), drilling, cutting, chamfering and other complex processes.

What problems can we solve?

-Customization needs are difficult to meet: flexible design support can be provided, and non-standard customization can be achieved based on customer drawings or samples.

-Lack of quality consistency: Through strict ISO quality management system, ensure consistent performance of each batch of products.

-Long delivery cycle: Optimize production process, regular products can be delivered within 15-25 days, and urgent orders can be processed urgently.

-Difficulties in cross-border cooperation communication: Equipped with a multilingual foreign trade team to provide one-stop service from technical consultation to after-sales.

-Cost control pressure: With the advantages of large-scale production and supply chain, we provide competitive prices while ensuring quality.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

Customer Case (Anonymous)

-German semiconductor equipment manufacturer: Customized high-temperature resistant observation window quartz plate for etching machine upgrade project, meeting the requirements of high cleanliness and dimensional tolerance ± 0.05mm, has been stably supplied for 3 years.

-American Optical Laboratory: Customized quartz window for UV laser, double-sided optical polishing, transmittance>90%, supporting the development of its new spectrometer.

-Japanese medical equipment company: Mass customization of quartz carrier plates for biological detectors, achieving corrosion resistance and high transparency, with a yield rate of 99.8%.

-Korean electronics company: Collaborate to develop quartz brackets for semiconductor heat treatment, optimize heat distribution design, and help customers improve yield by 15%.

We are not only manufacturers of quartz plates, but also partners in your technical field. Whether it's sample testing or bulk orders, we will help you improve project success rates with a professional attitude and reliable products.

If you have customized quartz plate requirements, please feel free to send drawings or specifications for consultation. Our engineers will provide you with optimization solutions and quotations within 24 hours to help you quickly advance the project!

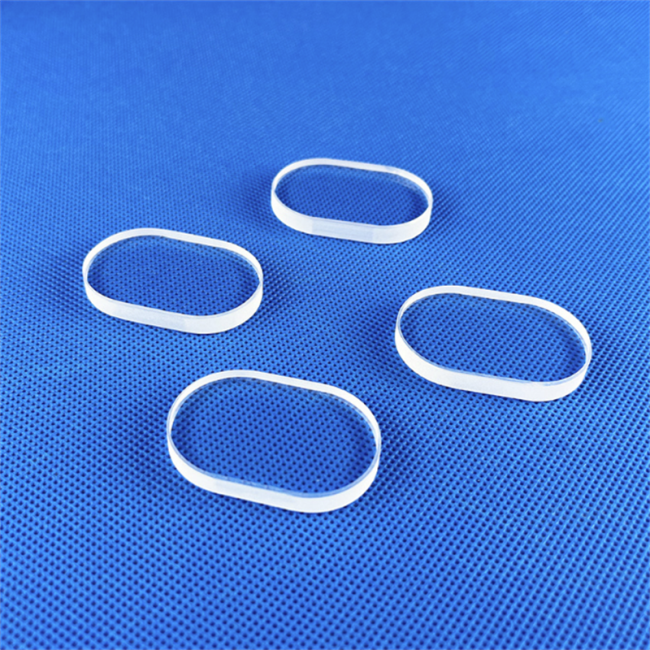

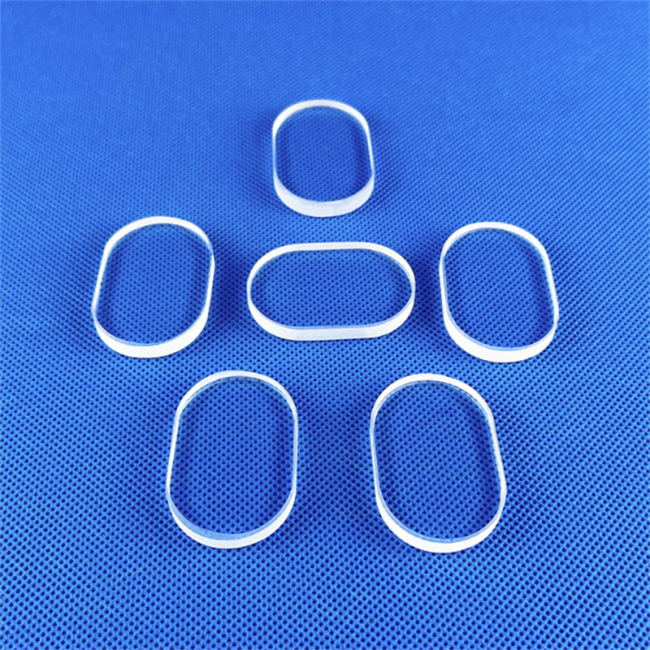

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.