T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Q: Are you looking for high-purity, high-temperature resistant, and chemically stable quartz materials?

Answer: We provide customized quartz rods to meet your needs for precision dimensions, special performance, and mass production.

Q: Are you concerned that the performance of the quartz rod may not meet the standard, which could affect the equipment or experimental results?

Answer: We use high-purity raw materials and precision processes to ensure that our products have excellent thermal stability, corrosion resistance, and optical performance.

Q: Do you need non-standard sizes or special shapes of quartz rods, but cannot find a suitable supplier?

Answer: We focus on customized production and can adapt to personalized needs in fields such as semiconductors, photovoltaics, optics, and laboratories.

As a manufacturer specializing in customized quartz products, we provide high-precision and durable quartz rod customized production services to customers worldwide. With advanced production processes and strict quality control systems, we are able to meet the diverse needs of different industries for quartz rods and provide customers with professional and reliable solutions.

Product application areas

Quartz rods are widely used in various high-end fields due to their excellent physical and chemical properties:

-Semiconductor and Optoelectronics Industry: Used for wafer processing, lithography equipment, laser components, etc.

-Laboratory and research equipment: as core components of high-temperature reaction vessels, optical supports, and analytical instruments.

-Lighting industry: used for manufacturing high stability lamps, ultraviolet lamps, and special light sources.

-Industrial high-temperature treatment: used as a high-temperature resistant support or transmission component in heat treatment furnaces and sintering equipment.

-Medical devices: applied to high-purity reagent containers, medical laser equipment, etc.

Core advantages of the product

1. High purity material: Using 99.99% or more high-purity quartz sand raw materials to ensure that the product has excellent transparency, temperature resistance, and chemical stability.

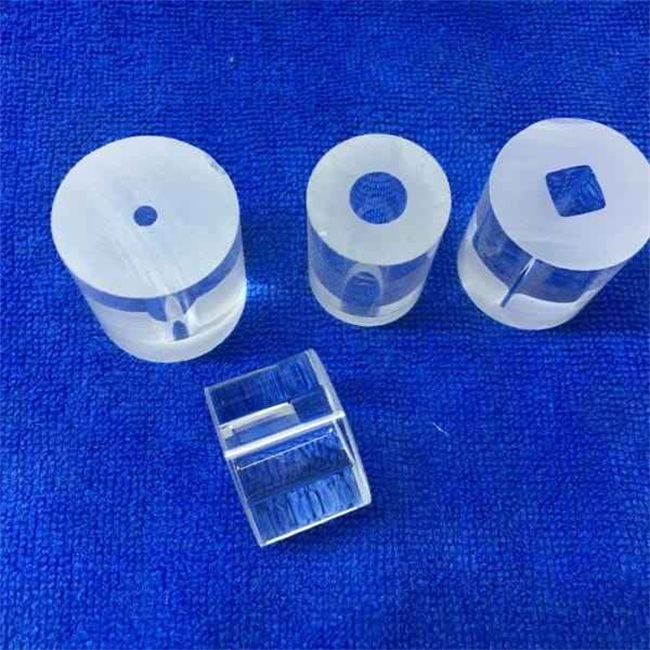

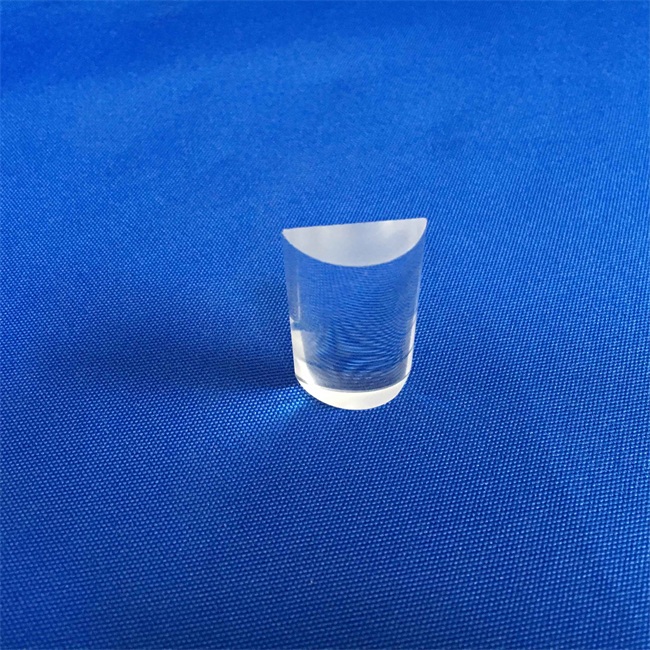

2. Precision machining capability: It can produce quartz rods with a diameter of 1mm-200mm and a length of up to 3000mm, with precise tolerance control up to ± 0.05mm. The surface finish can be customized according to requirements.

3. Excellent temperature resistance: softening point up to 1730 ℃, long-term use temperature up to 1200 ℃, extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), excellent heat shock resistance.

4. Customized design: Supports comprehensive customization of specifications, shapes, apertures, end face treatments, etc. based on customer drawings or requirements.

5. Strict quality inspection system: Each batch of products undergoes multiple tests such as dimensional accuracy, light transmittance, bubble content, compressive strength, etc., and material reports are provided.

What problems can we solve

-Alternative challenge: Provide customized alternative solutions for customers looking for special specifications or high-performance quartz rods to reduce equipment modification costs.

-Performance bottleneck: Help customers solve production efficiency issues caused by insufficient material purity, poor temperature resistance, or insufficient dimensional accuracy.

-Unstable supply chain: Provide stable and reliable quartz rod supply to international customers, shorten delivery time, and reduce procurement risks.

-Technical adaptation: Assist customers in optimizing the design of quartz rods to better adapt to specific equipment or process requirements.

Why choose us

1. Accumulated experience in foreign trade: Over ten years of experience in international markets, familiar with standards and demands in different regions, and providing multilingual technical support.

2. Controllable production throughout the entire process: from raw material screening, melting, rod pulling to precision processing, achieving independent production throughout the entire process to ensure quality and delivery time.

3. Quick response mechanism: A professional foreign trade team provides inquiry responses within 24 hours, supports small batch trial orders, and flexibly cooperates with customer project progress.

4. Cost optimization plan: Through process optimization and large-scale production, we provide customers with competitive prices while ensuring quality.

Customer Case (Anonymous)

-European semiconductor equipment manufacturer: Customized high-precision quartz rods with a diameter of 80mm and a length of 1200mm for its new generation lithography machine, with tolerances controlled within ± 0.03mm, successfully replacing the original supplier and improving equipment stability.

-American laboratory instrument company: Customize multiple batches of capillary quartz rods with different pore sizes for the development of new analytical equipment. The product purity and size consistency have been highly recognized by customers, establishing long-term cooperative relationships.

-Asian LED manufacturer: Customized quartz rod bracket for their high-temperature sintering furnace that can withstand 1300 ℃ continuous operation, with a service life extended to twice that of the original product, significantly reducing customer maintenance costs.

As a reliable partner in the global quartz product supply chain, we take materials science as the core and customization as the path to help customers overcome technological bottlenecks and optimize product performance. Whether you need standard specifications or complex designs of quartz rods, we will deliver reliable solutions with professional craftsmanship and rigorous attitude.

What problems or challenges have you encountered during the use of your product? Welcome to leave a message and communicate with us. Our technical team will provide you with professional quartz material solutions.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.