T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2025-12-19 Origin: Site

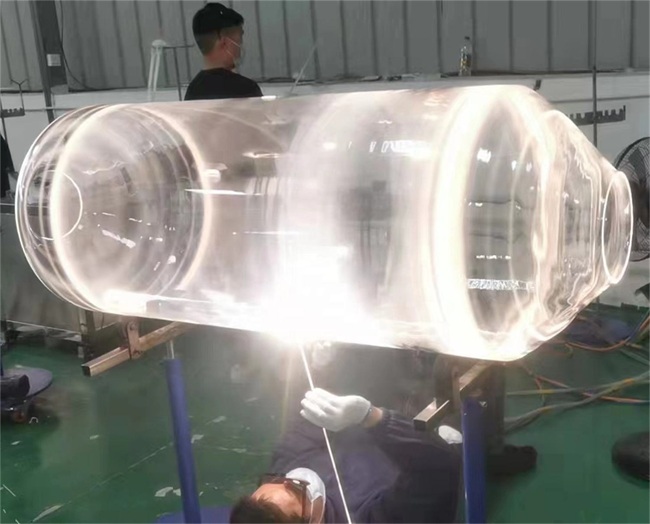

Large diameter quartz tubes (usually referring to outer diameters ≥ 200mm) are the core foundational materials for industries such as semiconductors, photovoltaics, optical fibers, and high-end lighting. As a professional quartz product manufacturer, we focus on providing customized OEM processing services for global customers, covering the research and development, production, and testing of ultra large, high-purity, and high-precision quartz pipes, meeting the stringent requirements of various industries for high-performance quartz materials.

Product application areas

Large diameter quartz tubes are widely used in the following industries due to their excellent physical and chemical properties:

-Semiconductor and Photovoltaic Industry: Used in high-temperature process environments such as diffusion furnaces, CVD reaction tubes, and solar cell manufacturing

-Optoelectronics and Lighting Industry: As a material for LED packaging tubes, UV lamps, and special lighting enclosures

-Chemical and laboratory equipment: corrosion-resistant reaction vessels, observation windows, analytical instrument components

-High temperature industrial field: melting observation window, heat treatment furnace tube, high temperature measurement protection tube

-Research and special applications: astronomical telescope mirror blanks, laser equipment components, aerospace components

Core advantages of the product

1. Excellent material performance

-High purity quartz material (SiO ₂ content ≥ 99.99%)

-Excellent high temperature resistance (softening point up to 1730 ℃)

-Extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃)

-Excellent transparency (wide band transmission from ultraviolet to infrared)

2. Precision machining capability

-Diameter range: 80mm to 600mm (larger sizes can be customized)

-The length can reach 3000mm, supporting the processing of ultra long pipes

-Wall thickness uniformity is controlled within ± 0.1mm

-Surface smoothness Ra ≤ 0.4 μ m (can be customized according to requirements)

3. Customized design support

-Support non-standard size and irregular structural design

-Capable of processing special structures such as flanges, interfaces, and openings

-Provide surface treatments such as polishing, sanding, coating, etc

-Support batch production with multi-level precision requirements

The key problems we can solve

1. Stability issue in high temperature environment: Ordinary glass is prone to deformation and crystallization at high temperatures, while our large-diameter quartz tube can work stably for a long time at 1200 ℃

2. Fracture caused by thermal shock: Excellent thermal shock stability can withstand rapid temperature changes (Δ T>1000 ℃)

3. Service life issues in chemical corrosion environments: except for hydrofluoric acid and hot phosphoric acid, it is resistant to most acid corrosion

4. Pollution risk in precision processes: High purity materials ensure that they do not introduce metal ion contamination, making them suitable for highly sensitive processes such as semiconductors

5. Size limitations for supporting large equipment: Breaking the standard size limitations and providing overall solutions for large diameters and ultra long sizes.

Customer Case Study Sharing

Case 1: European semiconductor equipment manufacturer

The customer requires a Φ 420mm × 2500mm quartz reaction tube for a new diffusion furnace, with an inner wall that is ultra smooth and an outer diameter tolerance of ± 0.15mm. By improving the drawing process and customizing the grinding scheme, we have successfully delivered a product that fully meets the customer's requirements for uniformity and surface quality, and has been running steadily for over 18 months.

Case 2: American Solar Energy Research Institute

The customer is developing a new type of photovoltaic material that requires a shaped quartz tube with high temperature resistance, high transparency, and a lateral observation window. Our team worked closely with the client engineer to design an integrated observation window structure, which avoided the risk of contamination caused by welding and helped the client achieve successful experiments.

Case 3: Japanese optoelectronic companies

The customer is looking for large-diameter quartz tubes for LED packaging that can replace imports, with a requirement of light transmittance>93% and high batch consistency. We have achieved product performance that fully meets the level of similar Japanese products through raw material selection and process optimization, reducing procurement costs for customers by 35% and establishing long-term supply relationships.

Overview of Technical Parameters

-Material: High purity transparent quartz glass, milky white quartz, UV quartz and other optional materials

-Diameter range: standard 80-600mm, special requirements can be negotiated

-Length: Maximum continuous length of 3000mm, longer dimensions can be achieved through connection technology

-Tolerance control: Outer diameter ± 0.1% -0.3%, wall thickness ± 5% -10% (depending on size and accuracy level)

-Temperature resistance: Long term use temperature of 1100-1200 ℃, short-term can reach 1450 ℃

-Main specifications: customizable production based on customer drawings or samples

What problems or challenges have you encountered during the use of your product? Welcome to leave a message and communicate with us.

(For example: High temperature deformation of quartz tube? Sealing failure? Urgent need for non-standard size? Our engineering team will provide you with targeted suggestions.)

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.