T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2025-11-17 Origin: Site

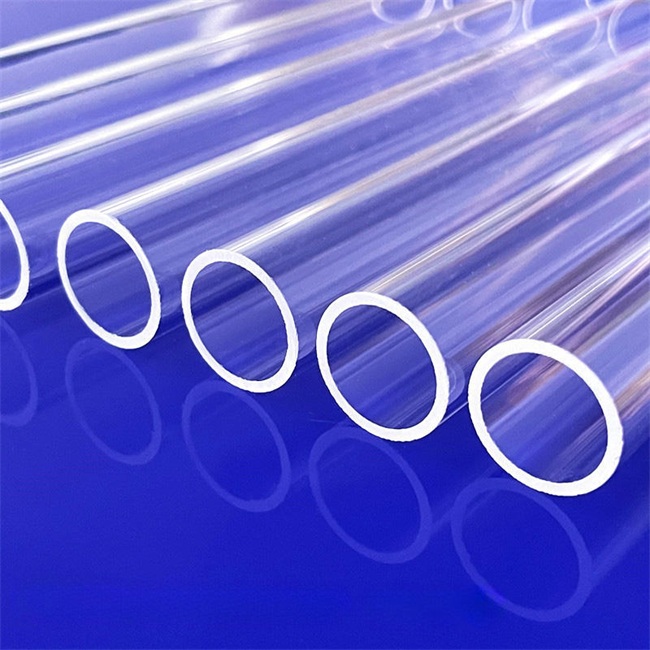

Quartz tubes are widely used in industries, scientific research, medical care, semiconductors and other fields due to their high purity, high temperature resistance, corrosion resistance and excellent optical properties. As a professional quartz products manufacturer, we are dedicated to providing high-precision and customized quartz tube contract manufacturing services for global customers. Through mature techniques and strict quality control, we help customers solve material challenges in complex environments.

Product application fields

Our custom quartz tubes are suitable for the following scenarios:

1. Semiconductor and optoelectronic industry: diffusion furnace tubes, etching process tubes, ultraviolet transmission pipes.

2. Laboratory and scientific research equipment: spectrometer Windows, high-temperature reaction vessels, vacuum sealing components.

3. Medical and Environmental Protection: Sterilization lamp tubes, ultraviolet lampshades for wastewater treatment, medical laser devices.

4. Industrial heating: Infrared heating tubes, observation Windows for melting furnaces, protective sleeves for high-temperature sensors.

Core advantages of the product

1. Material purity and stability

It adopts high-purity quartz sand (SiO₂≥99.99%), can withstand high temperatures up to 1200℃, has a low coefficient of thermal expansion and excellent thermal shock resistance.

2. Precision processing capability

It supports complex processes such as irregular cutting, drilling, bending and sealing, and the tolerance can be controlled within ±0.1mm.

3. Customized design support

The size, shape and surface finish (such as frosted, polished) can be adjusted according to customer requirements, and a coating can be applied to enhance performance.

4. Strict quality inspection

Each batch of products undergoes tests for light transmittance, bubble density, compressive strength, etc., and meets industry standards.

The customer problems we have solved

- Replace metals and ordinary glass: Solve the problem of short lifespan caused by high-temperature deformation and chemical corrosion.

- Enhance equipment efficiency: High ultraviolet transmittance (>90%) ensures the efficiency of ultraviolet equipment, and low heat loss optimizes energy consumption.

- Accelerate the R&D cycle: Respond quickly to customized demands to help research teams shorten sample verification time.

Customer Case (Anonymous)

Case 1: A European semiconductor equipment manufacturer needs to customize "U-shaped quartz tubes", which require vacuum sealing and high-temperature cycle resistance. We have addressed the cracking issue through a special annealing process, increasing the yield rate to 99.5%.

Case 2: An American environmental protection company ordered "ultraviolet disinfection lamp tubes". We optimized the coating technology to increase their ultraviolet transmittance by 8% and extend their service life to 12,000 hours.

Have you ever been troubled by insufficient precision, unstable performance or delayed delivery of quartz components during your product development or production process? Welcome to leave a message and communicate with us. We will clear the obstacles for you with professional solutions!

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.