T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-02-06 Origin: Site

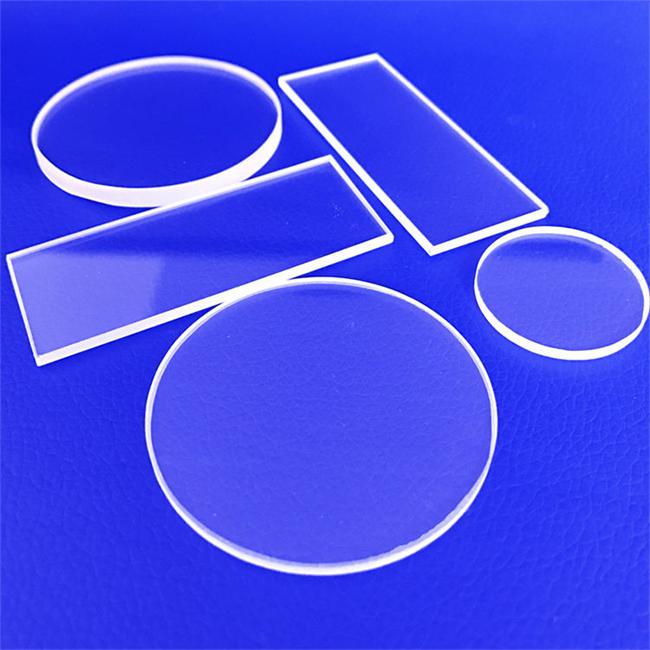

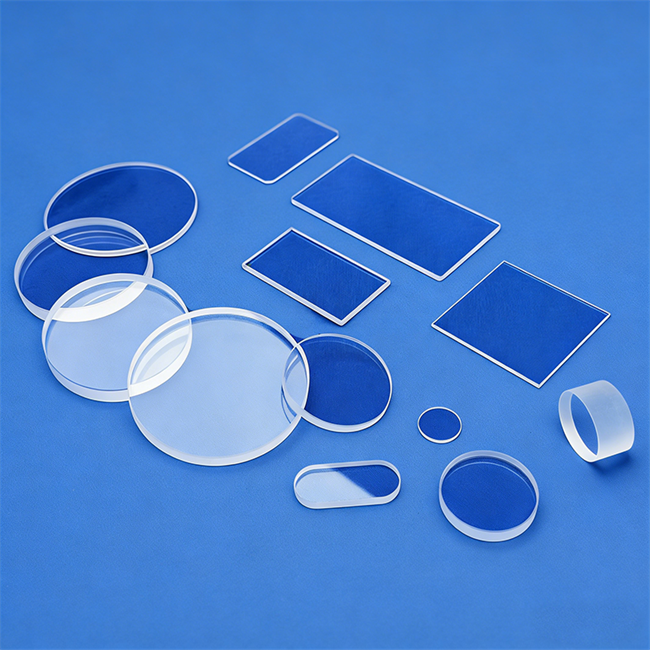

How can quartz plates meet your core needs?

Q: Are you looking for high-purity, high-temperature resistant, and corrosion-resistant precision plates?

Answer: Our customized quartz plates offer a purity of over 99.99% and a temperature resistance of up to 1200 ° C. They are widely used in semiconductor, optical, laboratory, and high-temperature industrial scenarios.

Q: Do you face processing difficulties with special dimensions, shapes, or precision requirements?

Answer: We support CNC precision cutting, drilling, polishing, coating and other full process processing, with a tolerance of up to ± 0.02mm, meeting non-standard customization needs.

Core application areas of the product

-Semiconductor and Photovoltaic Industry: Wafer Carrier Plates, Diffusion Furnace Tubes, Etching Equipment Components

-Optics and Optoelectronics: Lens substrate, UV transmission window, laser device protection board

-Laboratory and Medical Equipment: High Temperature Windows, Corrosive Environment Isolation Plates, Analytical Instrument Components

-Industrial high-temperature scenarios: melting observation window, heat treatment bracket, chemical anti-corrosion lining plate

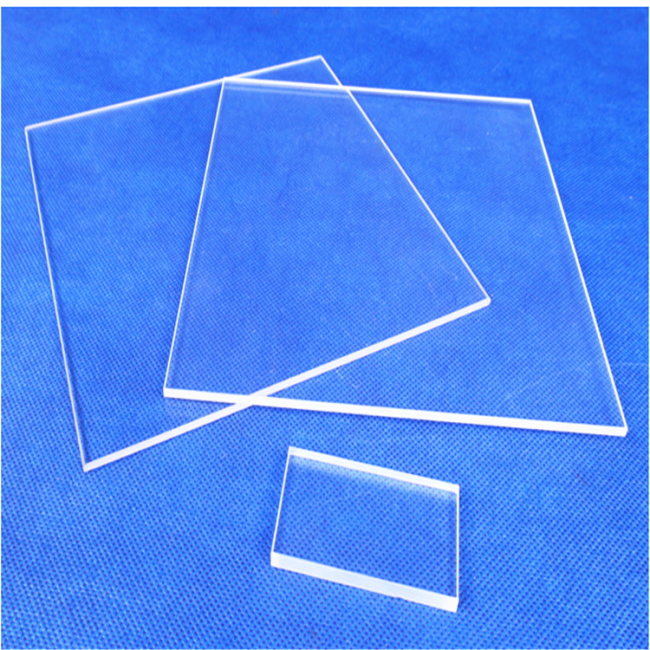

Product Advantage Analysis

1. Excellent material performance:

-Purity ≥ 99.99%, coefficient of thermal expansion as low as 5.5 × 10 ⁻⁷/℃

-Excellent transmittance (UV to IR band), dielectric strength>15kV/mm

-Acid and alkali resistant corrosion (except hydrofluoric acid), long-term use without deformation

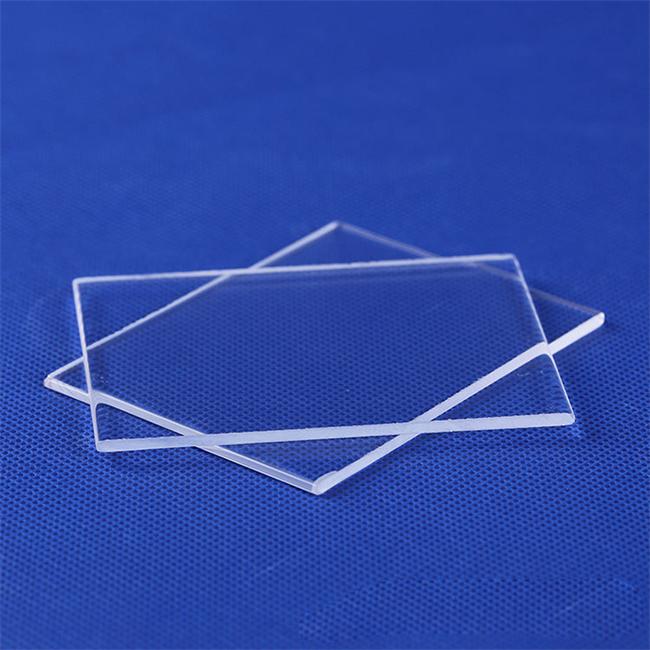

2. Leading processing technology:

-Five axis CNC precision machining, capable of processing ultra-thin plates with a thickness of 0.1mm

-Nano polishing technology, surface roughness Ra ≤ 0.2 μ m

-Laser cutting and ultrasonic drilling, forming complex shapes in one go

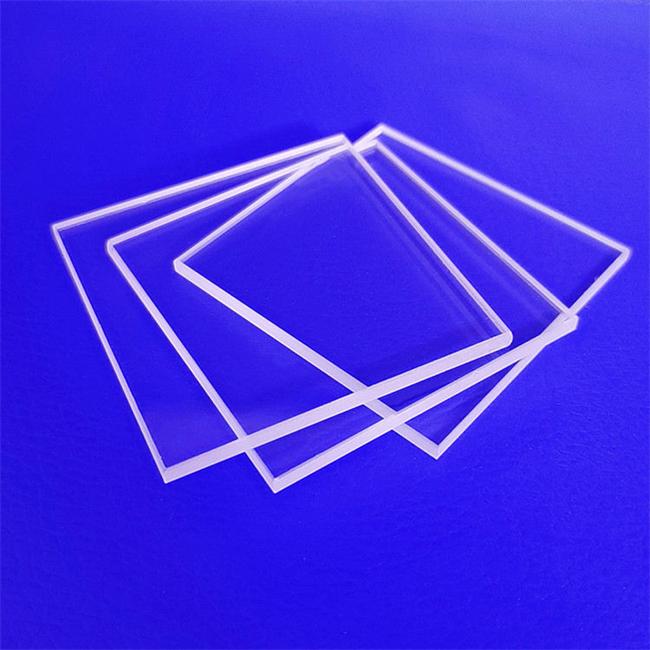

Specification customization service system

Size specifications: Thickness 0.1-150mm, maximum layout 2000 × 1500mm

Shape accuracy: circular, rectangular, and irregular cutting, chamfering, slotting, and stair design

Surface treatment: matte, optical polishing, coating (anti reflective, reflective, conductive)

Performance enhancement: doping modification (UV absorption, infrared reflection), microporous array

Addressing the 3 major pain points in the industry

1. High temperature deformation problem: Quartz plates have 20 times better thermal stability than ordinary glass at 1000 ° C environment

2. Insufficient purity pollution process: Vacuum melting process is used, with heavy metal content<1ppm

3. Long delivery cycle: Standardized modules+customized processing, regular orders delivered within 15 days

Customer Application Case (Anonymous)

-A German semiconductor equipment supplier: Customized Φ 450mm wafer carrier board to replace the original alumina material, resulting in an 8% increase in yield rate

-American Optical Laboratory: Developing high transmittance quartz windows in the ultraviolet band, with a transmittance of>95% @ 200nm

-Japanese new energy company: Multi layer quartz support for high-temperature sintering furnace, extended service life to 3 years (formerly 1.5 years)

-Middle East Petrochemical Customer: Corrosion resistant observation window component, continuously operated for 18 months without failure in strong acid environment

Whether it's prototype development or bulk procurement, we provide sample testing and solution optimization. Submit your specification requirement form, and within 24 hours, you will receive a triple response of feasibility analysis, quotation, and process plan. Make a professional quartz plate processing factory a reliable extension of your supply chain.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.