T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

Q: Are you looking for precision materials with high temperature resistance and strong chemical stability?

A: The high-purity quartz products we provide can withstand high temperatures above 1200 ℃, resist most acid corrosion, and solve the problem of material failure in extreme environments.

Q: Have you been affected by standard size limitations that have impacted project progress?

A: We provide full-size customization services, from millimeter level micro components to meter level large components, to accurately match your special specification requirements.

Q: Do you face comprehensive challenges in optical performance, thermal stability, or electrical insulation?

A: Our quartz material has excellent optical transmittance, extremely low thermal expansion coefficient, and outstanding electrical insulation, providing one-stop solutions for complex working conditions.

Core products and application areas

1. Product scope

-Semiconductor quartz products: diffusion tubes, boats, carriers, photomask substrates

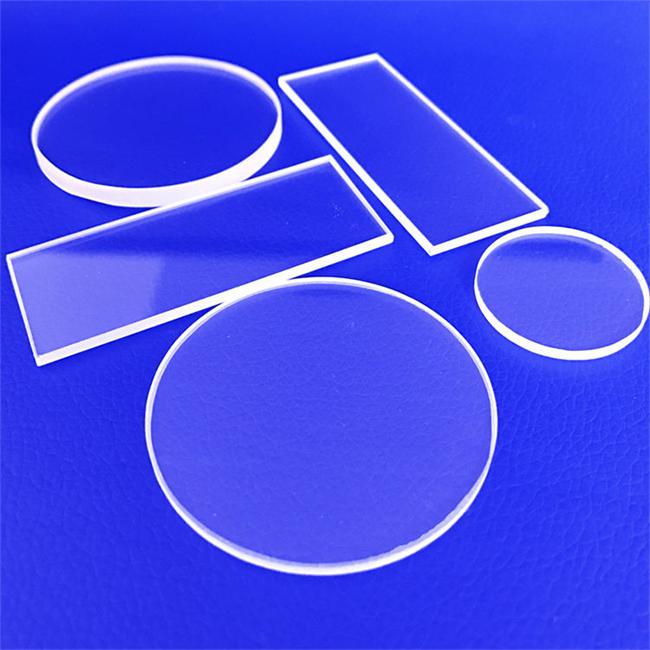

-Optical quartz products: lenses, window panels, prisms, ultraviolet and infrared optical components

-Laboratory and industrial equipment: beakers, test tubes, reactors, observation windows, insulation panels

-Customized special components: photovoltaic industry melting crucible, LED lighting quartz tube, photovoltaic quartz boat

2. Application scenarios

-Semiconductor Manufacturing: Bearing and Protection of High Temperature Process Links

-Optoelectronics and lasers: high transmittance, low thermal expansion optical components

-Chemical and Pharmaceutical: Corrosion resistant Experimental Equipment and Production Containers

-New Energy and Research: Photovoltaic Crystal Growth, High Temperature Experimental Equipment

Product advantage: Why is quartz an ideal material?

1. Ultimate temperature resistance

The softening point is as high as 1730 ℃, and the long-term use temperature is 1100 ℃ -1200 ℃, without deformation or crystallization.

2. Chemical inertness

Except for hydrofluoric acid and hot phosphoric acid, it is resistant to almost all acids, bases, and organic solvents, with a purity of over 99.99%.

3. Excellent optical performance

UV to infrared full spectrum high transmittance (transmittance>93%), stable refractive index, and strong radiation resistance.

4. Dimensional stability

The coefficient of thermal expansion is as low as 5.5 × 10 ⁻⁷/℃, ensuring almost unchanged dimensions in precision environments.

5. Electrical and mechanical properties

High insulation resistance, strength increases with temperature, and there is no volatile pollution in a vacuum environment.

Customization ability: full control from drawings to finished products

Size customization: thickness 0.1mm-200mm, diameter 1mm-1500mm, irregular cutting

Shape customization: tubes, plates, rods, rings, boats, vessels, and complex three-dimensional structures

Surface treatment: polishing (optical grade, mechanical grade), sanding, punching, coating

Purity grade: ordinary quartz, high-purity quartz, synthetic quartz

Process support: CNC precision carving, hot bending, welding, laser cutting, vacuum coating

Problem solving: How can we create value for our customers?

1. Replace expensive imported components

Customized laser window blades for a European optoelectronic company, with performance equivalent to imports, reduced delivery time by 60%, and cost reduced by 35%.

2. Break through process bottlenecks

Designed a multi chamber quartz boat for a semiconductor client in North America, resulting in a 40% increase in wafer loading capacity and a 25% improvement in thermal uniformity.

3. Meet special environmental requirements

Provide high-pressure and high-temperature observation windows for Middle Eastern petrochemical enterprises, which can operate continuously for 18 months without corrosion in strong acid environments.

4. Accelerate the research and development process

Customize miniature quartz reactors for Australian research institutions, support their new material experiments, and assist the project in publishing results 6 months ahead of schedule.

Customer Application Case (Anonymous)

1. German automotive sensor manufacturer

Requirement: Transparent quartz sheath for engine high-temperature testing, capable of withstanding transient impact at 1300 ℃.

Solution: Using synthetic quartz material, design a double-layer hollow structure, and coat the inner wall with a heat-resistant film.

Result: The product has passed 2000 hours of continuous testing and has been purchased in bulk for use on its global production lines.

2. Japanese Semiconductor Equipment Company

Requirement: Quartz diffusion tube for 12 inch wafers, with a metal impurity content of less than 1ppm.

Solution: Use arc melted high-purity quartz sand to optimize gas flow channel design.

Result: The impurity content was controlled below 0.5ppm, and the customer listed us as a first tier supplier.

3. American Biotechnology Laboratory

Requirement: A miniature quartz reaction chip for DNA synthesis, integrating 128 microchannels.

Solution: Laser engraving+chemical etching process to achieve channel accuracy of ± 0.01mm.

Result: The chip reduces reagent usage by 90%, and customers have published core papers based on this product.

Whether you need standard quartz products or face special material challenges, we can provide a one-stop solution from technical consultation to finished product delivery. Contact us immediately for free samples and customized solutions - making precision quartz components the reliable cornerstone of your product innovation.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.