How can quartz rods meet your core needs?

Q: Are you looking for precision materials that can withstand extreme high temperatures and maintain chemical stability?

Answer: Our high-purity quartz rod can work stably at a high temperature of 1650 ° C, resist acid and alkali corrosion, and is an ideal choice for high-temperature observation windows, semiconductor carriers, and laboratory instruments.

Q: Have you experienced any impact on equipment performance due to the size discrepancy of quartz products?

Answer: We provide customized quartz rod processing with diameters ranging from 2mm to 300mm and lengths that perfectly match your equipment specifications.

Q: Are you concerned that the purity of quartz products may affect the production process?

Answer: We use 99.99% high-purity quartz sand raw material to ensure that the product is free of bubbles and impurities, meeting the needs of high-precision industries such as semiconductors and photovoltaics.

The value of professional quartz rod processing

1. Excellent material performance

-Thermal stability: The coefficient of thermal expansion is only 5.5 × 10 ⁻⁷/℃, which can maintain dimensional stability under severe temperature changes

-Chemical inertness: resistant to all acid corrosion except hydrofluoric acid, does not react with most metals at high temperatures

-Optical characteristics: Transmittance of over 93% (UV to IR band), suitable for optical applications

-Electrical Insulation: With a resistivity of up to 10 ⊃1;⁶Ω· cm, it is an excellent insulation material

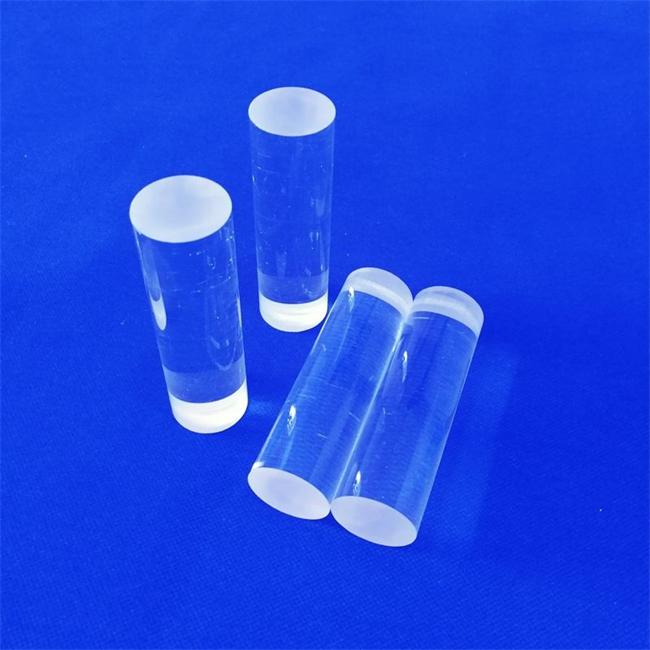

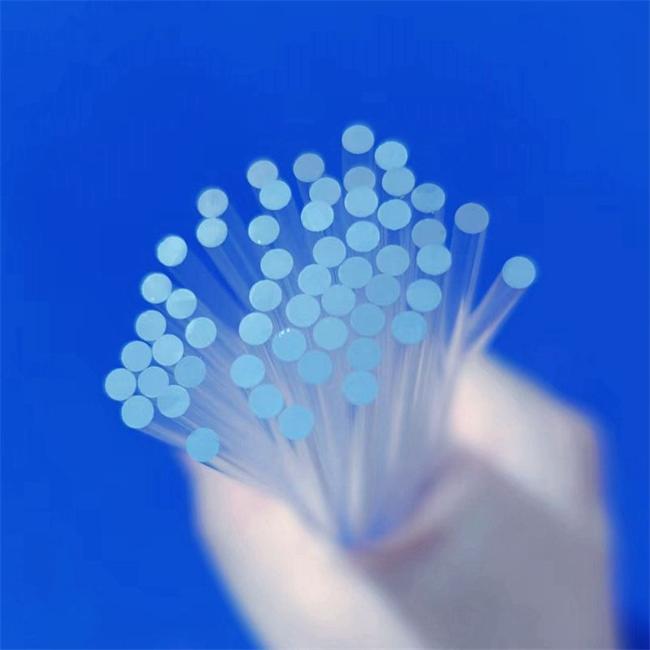

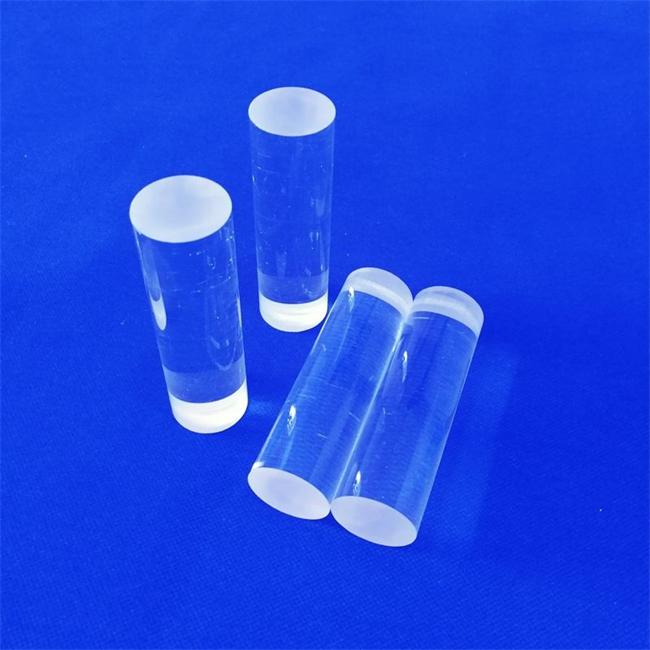

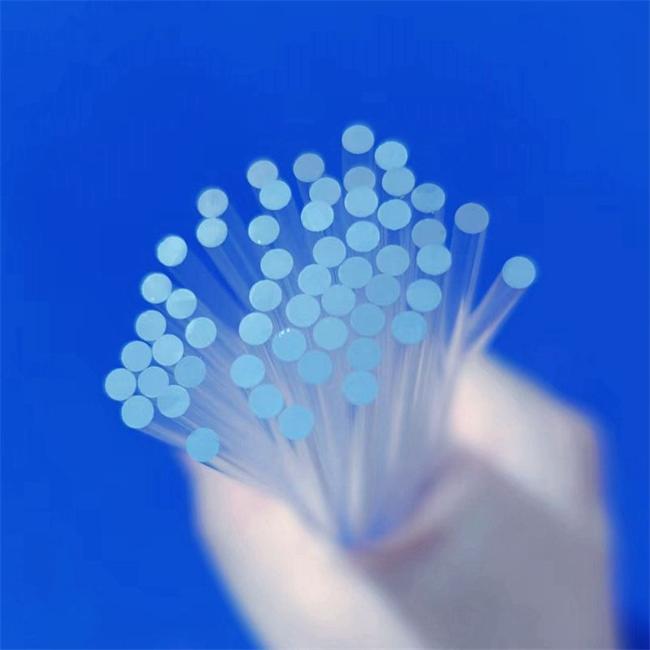

2. Precision machining capability

We have advanced CNC machining equipment and professional hot forming technology, which can provide:

-Precision dimensional machining: diameter tolerance ± 0.05mm, straightness 0.1mm/m

-Complex shape forming: special designs for step shafts, conical rods, irregular end heads, etc

-Surface treatment: secondary processing such as polishing, sanding, punching, etc. can be provided according to requirements

3. Comprehensive specification customization service

-Diameter range: 2mm micro rod to 300mm large rod

-Length customization: The standard length is 1000mm, and any length within 3000mm can be provided according to demand

-Material selection: transparent quartz, milky white quartz, UV grade quartz, low hydroxyl quartz

-Purity level: 99.99% (semiconductor grade), 99.95% (industrial grade) optional

Application Fields and Solutions

Semiconductor manufacturing industry

Problem: High temperature and clean environmental carriers are required during wafer processing

Solution: Our diffusion furnace tubes and boats made of low sodium high-purity quartz rods effectively reduce wafer contamination and improve yield

Optics and Lighting Industry

Problem: High power lighting fixtures require lamp tube materials that are resistant to high temperatures and have good transparency

Solution: High performance lamp tubes processed with our UV grade quartz rods have an 8% increase in transmittance and a 30% extension in lifespan compared to regular products

laboratory equipment

Problem: Experimental vessels need to be corrosion-resistant and easy to clean

Solution: Our chemical laboratory uses quartz rod products that can withstand strong acid and alkali environments, with a smooth surface that is not easily contaminated

photovoltaic industry

Problem: The high-temperature process in solar cell production has strict requirements for carrier materials

Solution: Customized quartz boat and load-bearing rod, with a 15% increase in thermal stability compared to traditional materials, reducing the risk of product deformation

Customer Application Case (Anonymous)

Case 1: German semiconductor equipment manufacturer

Requirement: A shaped quartz carrier rod for a new type of wafer annealing furnace, requiring deformation of less than 0.1% at high temperatures

Solution: We have developed quartz materials with low hydroxyl content (<5ppm) using a special annealing process. After 500 hours of continuous operation at 1250 ° C, the deformation rate of the product is only 0.08%, fully meeting the stringent requirements of our customers.

Case 2: American research laboratory

Requirement: Special quartz window for synchrotron radiation experimental setup, capable of withstanding high vacuum and radiation environments

Solution: Customize high uniformity quartz window panels with a diameter of 150mm and a thickness of 10mm, with a surface flatness of λ/10, to help customers successfully complete critical experiments.

Case 3: Japanese LED Manufacturer

Requirement: Improve the transmittance and weather resistance of UV-LED encapsulated quartz lenses

Solution: Optimize the melting process, provide quartz lenses with a transmittance of 90% in the ultraviolet band (250-400nm), and increase product lifespan testing to 8000 hours.

Whether you need standard specifications of quartz rods or customized requirements facing special application challenges, our engineering team is happy to provide you with professional advice and solutions. Contact us immediately for samples or technical consultation, and let us provide the most reliable material support for your project with 20 years of quartz processing experience.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.