T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-02-22 Origin: Site

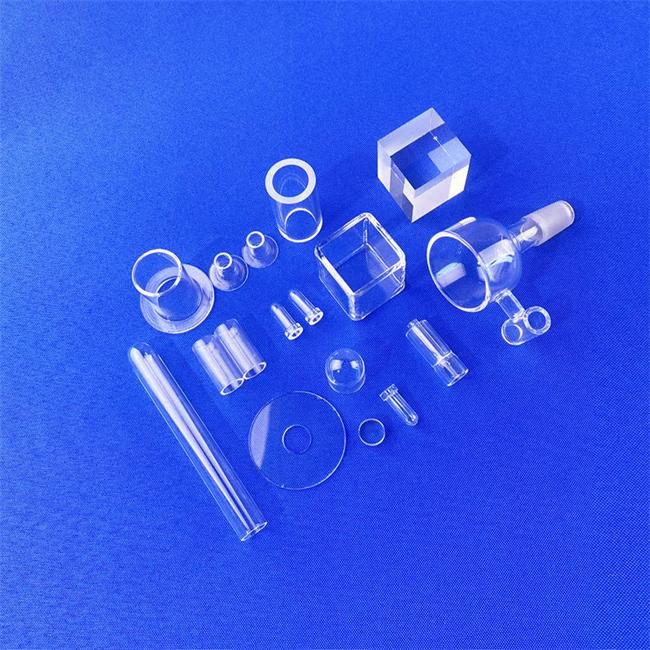

Luverre Quartz is a professional wholesale supplier of quartz tubes, dedicated to providing high-quality quartz glass tubes for industrial manufacturing, scientific research experiments, and heating equipment. Our main products include transparent quartz tubes, UV filtering quartz tubes, milky white quartz tubes, and various shaped deep processed quartz parts. The product has excellent high temperature resistance, thermal shock resistance, strong transparency, and electrical insulation performance, and is widely used in electric heating elements, photovoltaic electronics, fiber optic communication, and laboratory instruments. We have stable supply channels and mature processing technology, supporting non-standard customization and bulk supply. With strict quality control and efficient logistics distribution system, we are committed to becoming your reliable supply chain partner.

Have you also encountered these difficulties in finding quartz product partners globally?

Q: As a purchaser of quartz products, our biggest headaches are mismatched specifications, unstable delivery times, and difficulty in ensuring quality consistency when purchasing in large quantities. Can you solve these problems?

Answer: This is exactly what we have been specializing in customizing quartz products for 15 years. We control the purity of raw materials from the source and use full process CNC machining to ensure that the wall thickness tolerance of each batch of quartz tubes is controlled within ± 0.1mm. Whether it is small-diameter transparent quartz tubes used in experimental instruments or large-diameter milky white quartz tubes required by the photovoltaic industry, we can deliver them in bulk according to your drawings. In the past 12 months, we have completed over 300 customized orders for customers in 47 countries and regions worldwide, with a return rate of over 82%.

What core problems can quartz tubes solve?

Quartz tube, as a high-performance industrial basic material, is an irreplaceable solution for other materials in scenarios such as high temperature, high pressure, high transparency, and high cleanliness.

High temperature resistance and thermal stability issues

Ordinary glass will soften and deform above 300 ℃, while our high-purity quartz tube can be used for a long time at 1100 ℃, with a short-term temperature resistance of up to 1300 ℃. This feature solves the problem of substrate deformation in infrared heating equipment and semiconductor diffusion furnaces.

Transparency and Spectral Transmittance Issues

In fields such as UV sterilization, laser processing, photocatalysis, etc., material transmittance directly affects equipment efficiency. The far ultraviolet optical quartz tube we produce still has a transmittance of over 85% at a wavelength of 185nm, solving the problems of high energy consumption and incomplete sterilization caused by low ultraviolet transmission.

Chemical corrosion and cleanliness issues

In the semiconductor wet cleaning and photovoltaic velvet production processes, acidic and alkaline gas-liquid corrosion of the pipe wall is severe. Our synthetic quartz tube has a total metal impurity content of less than 5ppm, and its acid and alkali corrosion resistance is 30 times that of ordinary glass, fundamentally avoiding process pollution.

Compatibility issues between non-standard specifications and systems

Standard pipes are difficult to match with non-standard equipment. We support customized shapes such as square, D-shaped, conical, bent, flanged, ground, and sealed to solve your installation compatibility problems caused by equipment space limitations or special channel designs.

Our product advantage: not just "pipe", but also complete process support

1. Triple screening system for raw materials

We not only purchase quartz ingots, but also conduct three incoming tests on thermal stability, hydroxyl content, and bubble level for each batch of raw materials.

2. Full chain CNC molding capability

-Outer diameter range: 1.5mm~600mm

-Wall thickness range: 0.3mm~15mm

-Length range: 10mm~3500mm

-Irregular processing: The minimum curvature radius of the bent pipe can reach 1.2 times the diameter of the pipe

-Precision machining: sanding, polishing, cutting, drilling, threading, rounding, sealing

All key processes are equipped with CNC machine tools, which have strong consistency in batch products and support seamless connection between small batch trial production and large batch flipping.

3. Quality grading transparency

We categorize our products into three levels based on their terminal applications:

-Optical grade: used for laser, lithography, and optical communication, with separate testing reports for transmittance indicators

-Industrial grade: used for heating, environmental protection, chemical industry, with a focus on ensuring dimensional accuracy and temperature resistance performance

Customer Application Case (Anonymous)

Case A: German infrared heating equipment manufacturer

The customer has been purchasing milky white quartz tubes for a long time, which are used for printing and drying equipment. The color difference between batches of the original supplier was significant, resulting in inconsistent appearance of the equipment at the factory. We have customized a dedicated color code management system for it, controlling the color difference value within Δ E<1.5, while tightening the wall thickness tolerance from ± 0.3mm to ± 0.1mm, improving thermal efficiency by 12%. Our customers have included us in the global preferred supplier list.

Case B: Korean semiconductor consumables trader

The customer received an urgent order to deliver 2000 irregular quartz tubes for 8-inch wafer cleaning equipment within 10 days. We completed all production from drawing confirmation, raw material allocation to three consecutive shifts, and shipped to Incheon Port on the 9th day. The client will subsequently add an annual framework agreement to cover their business in Japan and Taiwan.

Case C: Middle East Desalination Research Institute

The institution uses ultraviolet quartz tubes for seawater pretreatment and sterilization. The original European brand had a delivery time of up to 8 weeks, which limited the progress of the experiment. We have customized UV transparent quartz tubes that are completely interchangeable with imported brands, with consistent transparency indicators and shortened delivery time to 10 days. At present, this tube type has been applied to its third-generation prototype.

We are ready to participate in your next quartz tube project

Whether you urgently need one sample for equipment testing or require a stable supply of 5000 units in bulk, we are willing to start working together with just one drawing or one phone call.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.