T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

In precision industrial fields such as semiconductors, photovoltaics, optical fibers, optoelectronics, and high-end laboratory equipment, quartz tubes are a key foundational material whose quality directly determines the performance, yield, and safety of the final product. It is crucial to choose a quartz tube supplier with strong technical strength and stable and reliable quality. Among numerous manufacturers, Luverre Quartz stands out as a trusted industry partner due to its ultimate pursuit of high-purity materials, exquisite manufacturing processes, and comprehensive product solutions.

Core products and application areas

The products provided by Luverre Quartz are not universal quartz tubes, but professional solutions optimized for different demanding application scenarios. Its main product lines and applications include:

1. High purity transparent quartz tube

Application: diffusion and oxidation processes in semiconductor manufacturing; Thermal insulation cover and carrier for polycrystalline silicon ingot furnace in the photovoltaic industry; Lampshades for high-end light sources such as xenon lamps and halogen lamps.

Addressing pain points: In high temperature environments (>1000 ° C), metal impurities can contaminate the wafer, leading to device failure. Luverre's high-purity quartz tubes can effectively prevent pollution, ensuring the electrical performance and high yield of semiconductors and photovoltaic cells.

2. UV transparent quartz tube

Application: UV sterilization (UVC) equipment; Water treatment photoreactor; Medical and scientific research ultraviolet lamps.

Addressing pain points: Ordinary glass can block short wave ultraviolet radiation (such as 254nm). Luverre's UV grade quartz tubes have extremely high UV transmittance (>90% @ 254nm), ensuring maximum sterilization and photochemical reaction efficiency.

3. Low hydroxyl quartz tube

Application: Fiber preform deposition tube; Laser cavity; High temperature window.

Addressing pain points: Hydroxyl groups (OH -) can produce absorption peaks in the infrared band, leading to fiber signal attenuation or affecting laser energy output. Luverre's low hydroxyl quartz tube (OH content can be controlled at extremely low levels, such as<5ppm) ensures low loss in optical transmission and high efficiency in laser systems.

4. Customized fossil quartz tubes and devices

Application: Processing of irregular pipes, flanged pipes, closed end pipes, etc. according to customer drawings.

Addressing pain points: Standard products cannot meet the design requirements of special equipment. Luverre has strong deep processing capabilities and can provide one-stop customized services to shorten customers' equipment research and assembly cycles.

Core advantages and competitiveness of the product

The product advantage of Luverre Quartz is not limited to a single dimension, but runs through the entire chain of materials, processes, and services.

Advantage 1: Excellent material purity

Using high-quality natural quartz sand or synthetic quartz raw materials, strict raw material screening and purification processes ensure that the product has extremely low metal impurity content (such as total content of Al, Fe, K, Na, etc.<50ppm), fundamentally eliminating the risk of pollution at high temperatures.

Advantage 2: Exquisite hot and cold processing techniques

We have advanced continuous melting furnaces, electric melting furnaces, and CNC precision machining equipment. The product has excellent thermal stability (softening point up to 1730 ° C), extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/° C), as well as excellent geometric dimension accuracy and surface smoothness, ensuring no deformation or cracking during rapid temperature rise and fall processes.

Advantage 3: Strict Quality Control System

Traceable quality management is implemented throughout the entire process from raw material storage to finished product delivery. Equipped with spectral analyzer, UV spectrophotometer, geometric dimension measuring instrument and other testing equipment, strict testing is carried out on the key parameters (such as purity, transmittance, hydroxyl content, dimensional tolerance) of each batch of products to ensure consistency and reliability of performance.

Advantage 4: Professional technical support and services

Luverre not only provides products, but also offers solutions. Its technical team is well versed in various industry application processes and can provide customers with selection guidance, application problem diagnosis, and customized development services, becoming a reliable partner for customers on the road to technological upgrading.

What key problems can Luverre quartz solve for you?

Choosing Luverre quartz means you can free yourself from the common challenges in the following industries:

Solving the "pollution problem": Say goodbye to wafer contamination and product yield fluctuations caused by impurity precipitation in quartz tubes in semiconductor and photovoltaic manufacturing.

Addressing the 'efficiency challenge': In the field of UV applications, achieving the highest UV light output efficiency ensures that sterilization and chemical reaction effects meet design standards.

Solving the "loss problem": In the fields of fiber optic communication and laser, using low hydroxyl quartz tubes significantly reduces signal attenuation and energy loss.

Solving the "reliability problem": In high temperature, strong corrosion or thermal shock environments, with excellent physical and chemical properties, the stability and service life of equipment operation are greatly improved, reducing unplanned downtime.

Solving the "customization problem": Faced with special research and development or equipment requirements, obtaining quick response and professional design and processing support to accelerate project progress.

Luverre Quartz is a professional supplier specializing in the research and manufacturing of high-performance quartz materials. Its products are characterized by high purity, high precision, and high stability, which deeply meet the strict requirements of high-end manufacturing industries such as semiconductors, photovoltaics, and optoelectronics for basic materials. Whether it is chip manufacturing that pursues ultimate purity, sterilization equipment that requires efficient UV transmission, or the optical communication field that requires low loss, Luverre Quartz can provide reliable products and professional services that match it.

For enterprises seeking stable quality, leading technology, and committed to enhancing their product competitiveness, Luverre Quartz is undoubtedly a strategic supplier worth evaluating and cooperating with.

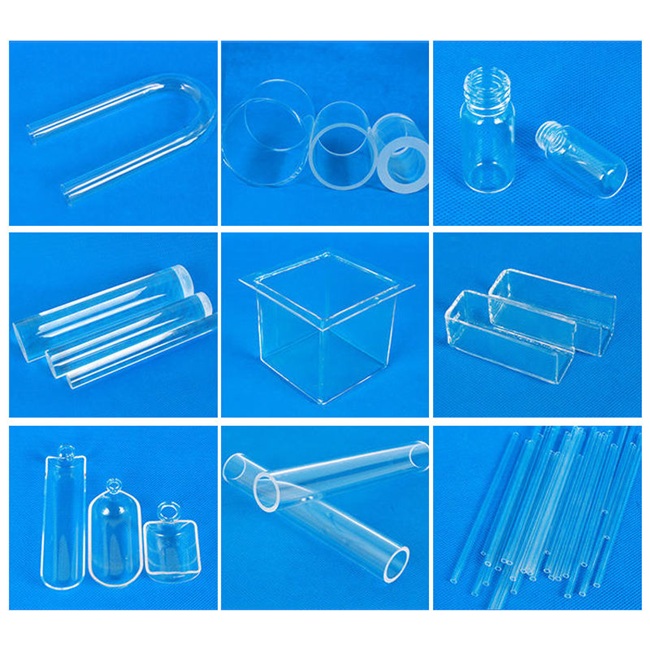

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.