T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2024-11-20 Origin: Site

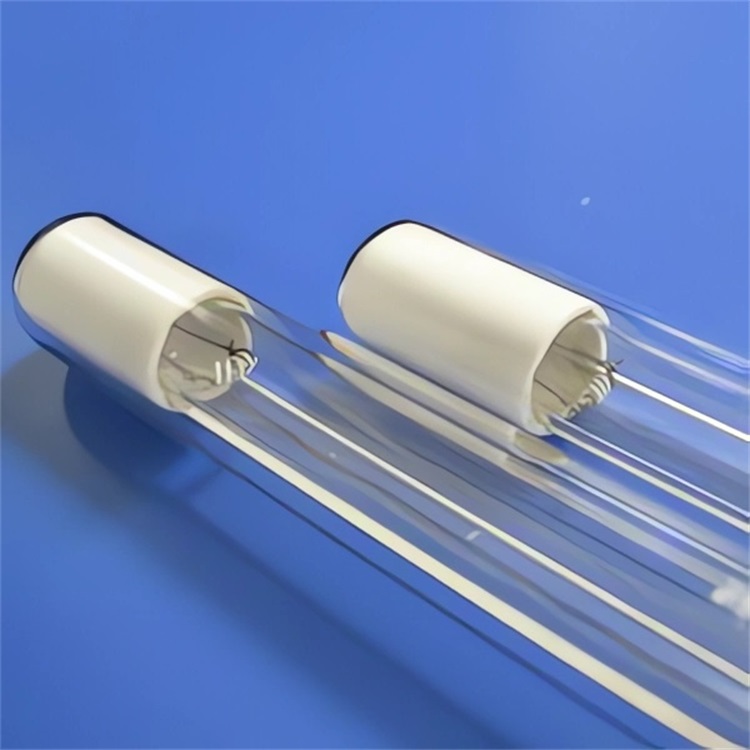

As a high-performance material, quartz glass tubes are widely used in laboratories due to their excellent high temperature resistance, corrosion resistance and optical properties. Whether it is the storage and processing of chemical reagents, or the fabrication and testing of optical components, quartz glass tubes play an indispensable role.

The characteristics of quartz glass tubes

High temperature resistance: quartz glass tubes have a high melting point (about 1720 ° C), which allows them to work stably in high-temperature environments and is not easily deformed or melted, making them ideal for high-temperature experiments.

Corrosion resistance: Quartz glass tubes are highly stable to most chemical substances, including strong acids, alkalis, and various organic solvents, making them less susceptible to corrosion and ensuring the accuracy of experimental results.

High light transmittance: Quartz glass tubes have excellent optical transmission, especially in the ultraviolet and infrared light bands, which makes them particularly important in the manufacture of optical instruments.

Good electrical insulation: quartz glass tubes are excellent electrical insulation materials and can be used in high voltage or high frequency electric fields to ensure experimental safety.

Types of quartz glass tubes

According to different production processes and uses, quartz glass tubes can be divided into various types, including the following:

Continuous fusion quartz glass tubes: This is the most common type on the market, with high quality, large output and low cost. Its silica purity is usually greater than 99.9%, and it is widely used in electric light sources, semiconductors, optical fibers, and chemical industries.

Gas-smelting quartz glass tubes: produced by melting quartz powder with hydrogen-oxygen flame, suitable for quartz glass tubes with larger diameter and thicker wall thickness, mainly used for diffusion tubes, furnace tubes, etc.

Fused quartz glass tubes: produced by vacuum pressurized electrofusion method, with low hydroxyl content, suitable for occasions with high hydroxyl requirements, such as boiler tubes.

Plasma quartz glass tubes: the use of plasma flame melting quartz powder, mainly used for the production of optical fiber.

High-temperature resistant quartz glass tubes: The outer surface of the quartz glass tubes is coated with a high-purity Al 2O or SiC coating to improve its high-temperature resistance and is suitable for experiments in extreme high-temperature environments.

Specification of quartz glass tubes

The specifications of quartz glass tubes are diverse and can be customized according to specific needs, including the following aspects:

Outer diameter: Common outer diameter specifications include 1mm, 2mm, 3mm, 4mm, 5mm, etc. Smaller diameter quartz glass tubes are often used to make miniature experimental devices or optical components.

Wall thickness: The wall thickness is usually between 0.5mm and 5mm, and the common wall thickness specifications are 1mm, 2mm, 3mm, etc. Thicker-walled quartz glass tubes can withstand greater pressure and impact force, making them suitable for high-pressure experiments.

Length: The length can be customized according to the needs. Common length specifications are 10cm, 20cm, 30cm, 50cm, etc. Longer quartz glass tubes are often used to make reactors or expand the volume of reaction devices.

Optical properties: According to experimental requirements, quartz glass tubes with specific optical properties such as high temperature resistant light transmission tubes, ultraviolet light transmission tubes, and infrared light transmission tubes can be selected.

Application scenario

Chemical reagent containers: Due to their corrosion resistance and high transparency, quartz glass tubes are often used as storage containers for chemical reagents, especially those with extremely high material requirements.

Optical components: In the manufacture of optical instruments, quartz glass tubes are widely used in the fabrication of optical components such as lenses, prisms, and filters to ensure the stability and reliability of optical performance.

Medical apparatus: In the medical field, quartz glass tubes are used to make various medical apparatus, such as high temperature sterilization equipment, optical components of medical analytical instruments, etc., because of their non-toxic, corrosion-resistant and high temperature resistance.

Laboratory equipment: In the laboratory, quartz glass tubes are often used to make various instruments, such as reactors, evaporation dishes, test tubes, etc., to meet various complex experimental requirements.

Quartz glass tubes are widely used in laboratories due to their excellent high temperature resistance, corrosion resistance and optical properties. Whether it is the storage and processing of chemical reagents, or the fabrication and testing of optical components, it is inseparable from the support of quartz glass tubes. With the continuous development of science and technology, the production process and performance of quartz glass tubes are also constantly improving, providing more reliable and efficient material support for laboratory research and industrial production.

Luverre Quartz is a manufacturer specializing in quartz tubes.We have over 18 years experience with the production of quartz tubes, we will be your reliable partner on quartz tubes and other quartz items.

Luverre Quartz can produce customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.