T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2025-11-05 Origin: Site

Quartz glass tubes, with their excellent temperature tolerance as their core characteristic, play an irreplaceable role in many high-tech and industrial fields.

Core feature: Excellent temperature tolerance

The temperature tolerance of quartz glass tubes is their most notable attribute, mainly reflected in the following aspects:

1. Extremely high softening point: The softening point of quartz glass (mainly composed of high-purity silica SiO ₂) is as high as 1730 ℃. This means that below this temperature, quartz glass tubes can maintain their structural shape and mechanical strength without undergoing plastic deformation. This is much higher than ordinary soda lime glass (softening point of about 700 ℃) and most metal materials.

2. Excellent thermal shock stability: The thermal expansion coefficient of quartz glass is extremely low, about 5.5 × 10 ⁻⁷/K. This characteristic allows it to withstand severe temperature fluctuations without breaking. For example, pouring a quartz glass tube directly into cold water at high temperatures can usually be safe and sound. This thermal shock resistance is unmatched by other glass or ceramic materials.

3. High long-term use temperature: Quartz glass tubes can work stably for a long time in a high temperature environment of 1200 ℃, and their physical and chemical properties will not undergo significant decay.

Verifiable data sources: The key parameters mentioned above (softening point, thermal expansion coefficient) can be found in the Materials Science Handbook, relevant standards of the American Society for Testing and Materials (ASTM), and product technology white papers of well-known quartz glass manufacturers such as Meitu, Heraeus, Quartz, etc.

Product application: Key components in high-temperature environments

The excellent temperature resistance of quartz glass tubes makes them an ideal choice for the following application scenarios:

Semiconductor industry: Quartz glass tubes are used as wafer carriers (diffusion tubes), furnace tubes, and reaction chambers in photolithography, diffusion, oxidation, and CVD (chemical vapor deposition) processes for chip manufacturing. It must be kept pure in a corrosive gas environment up to 1300 ℃ to prevent contamination of silicon wafers.

Optoelectronic light source: used as the outer shell of high-intensity gas discharge lamps (such as xenon lamps, mercury lamps) and ultraviolet sterilization lamps. These light sources have extremely high internal temperatures and generate a large amount of ultraviolet light. Only quartz glass can withstand high temperatures and efficiently transmit ultraviolet light.

Photovoltaic industry: In the thermal field system of polycrystalline silicon and monocrystalline silicon ingot furnaces, quartz glass crucibles are the core containers that hold high-temperature silicon melts, and their purity and temperature resistance directly determine the quality of silicon ingots.

Laboratory and research equipment: widely used in tube furnaces, muffle furnaces, observation windows, and high-temperature chemical reaction vessels, providing a stable and reliable high-temperature environment for scientific research experiments.

High temperature observation window: In industrial kilns such as steel and glass melting furnaces, quartz glass windows allow operators to directly observe the internal melting state exceeding 1500 ℃ from the outside without being damaged.

Product advantages and problems solved

Based on its temperature tolerance, quartz glass tubes bring multiple core advantages to users and solve key problems:

1. Dimensional stability at high temperatures:

Solved the problem of uncontrolled product dimensional tolerances and process failures caused by material softening and deformation during heat treatment. For example, in semiconductor diffusion processes, the accuracy of wafer position is ensured.

2. Excellent thermal shock resistance:

Solved the production safety and equipment lifespan issues caused by component cracking and damage due to rapid temperature changes during equipment startup, shutdown, or process fluctuations. Greatly reducing maintenance costs and downtime risks.

3. High chemical purity and inertness:

At high temperatures, quartz glass has excellent corrosion resistance to most acids (except hydrofluoric acid and hot phosphoric acid) and metal melts. This solves the problem of material contamination in high-temperature processes, such as high-purity silicon and special alloys.

4. Excellent optical performance:

Capable of transmitting a wide range of light from ultraviolet to infrared. This solves the technical bottleneck of the light source industry that needs to withstand high temperatures and efficient light transmission (especially ultraviolet light) at the same time, and is the key to achieving efficient ultraviolet sterilization and special lighting.

The temperature tolerance of quartz glass tubes is not a single indicator, but a comprehensive and excellent characteristic composed of their high softening point, extremely low thermal expansion coefficient, and high long-term use temperature. This combination of characteristics makes it an irreplaceable fundamental material in fields such as semiconductors, optoelectronics, photovoltaics, and scientific research that have extreme temperature requirements. The value of its products lies in providing a stable, pure, and reliable high-temperature environment, directly ensuring the feasibility of high-end manufacturing processes, product quality, and production efficiency.

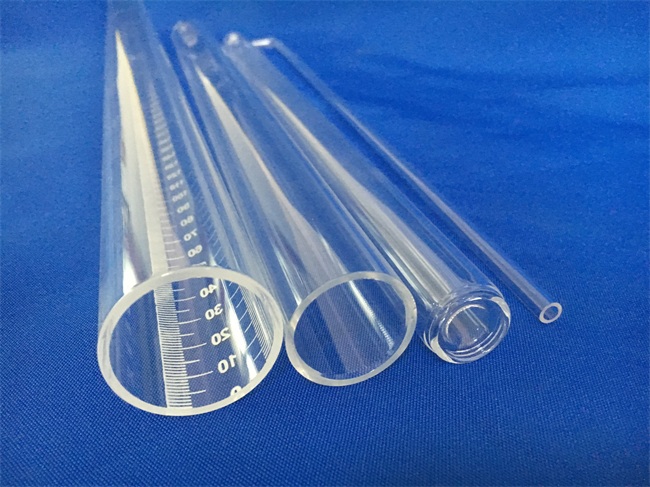

Luverre Quartz can manufacture customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.