T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-03 Origin: Site

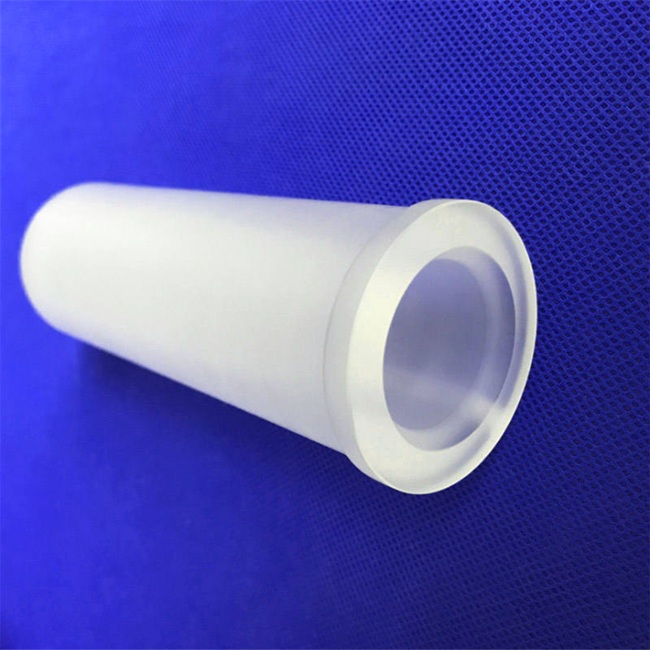

Quartz flanges, as key connecting components in high-end industrial equipment, are widely used in fields such as semiconductors, photovoltaics, optics, chemical engineering, and laboratory equipment. Its high purity, high temperature resistance, corrosion resistance, and excellent optical properties make it an ideal choice for harsh environments.

Luverre Quartz specializes in customizing and producing various specifications and sizes of quartz flanges and other quartz products, which are sold worldwide.

Core application areas of quartz flanges

Quartz flange is not a universal standard component, and its application is highly dependent on specific working conditions:

-Semiconductor manufacturing: used as connecting components for CVD, diffusion furnaces, and etching equipment, requiring extremely high purity and thermal stability.

-Photovoltaic industry: In crystal growth furnaces and photovoltaic glass production lines, it can withstand long-term high temperatures and thermal cycles.

-Optics and laser systems: As windows or connectors for precision optical equipment, excellent optical uniformity is required.

-Chemical and Pharmaceutical: Provides excellent acid and alkali resistance in corrosive media delivery systems.

-Research experimental equipment: used for customizing reaction vessels, vacuum systems, and high-precision measuring instruments.

Five key advantages of professional quartz flanges

1. Excellent thermal stability: The softening point is as high as 1730 ℃, and it can work in an environment of 1200 ℃ for a long time. The coefficient of thermal expansion is extremely low, and the thermal shock resistance is excellent.

2. Chemical inertness: Resistant to almost all acids, bases, and organic solvents except hydrofluoric acid and hot phosphoric acid.

3. High purity and low pollution: The SiO ₂ content is over 99.99%, avoiding contamination of sensitive processes.

4. Excellent optical performance: The light transmission range ranges from ultraviolet to infrared (170nm-2500nm), meeting special optical requirements.

5. Customization flexibility: It can be fully customized according to specific pressure, temperature, and connection standards.

Our customized service capability

As a professional quartz product manufacturer, we provide comprehensive customized solutions:

Customization of specifications and dimensions

-Diameter range: can be produced from small flanges of 10mm to large flanges of 1200mm

-Pressure rating: Can be designed for vacuum flanges (10 ⁻⁸ Pa) to high-pressure flanges (2.0MPa)

-Connection standards: Supports multiple standards such as ISO-KF, ISO-F, CF, ANSI, etc., and can also be customized according to drawings

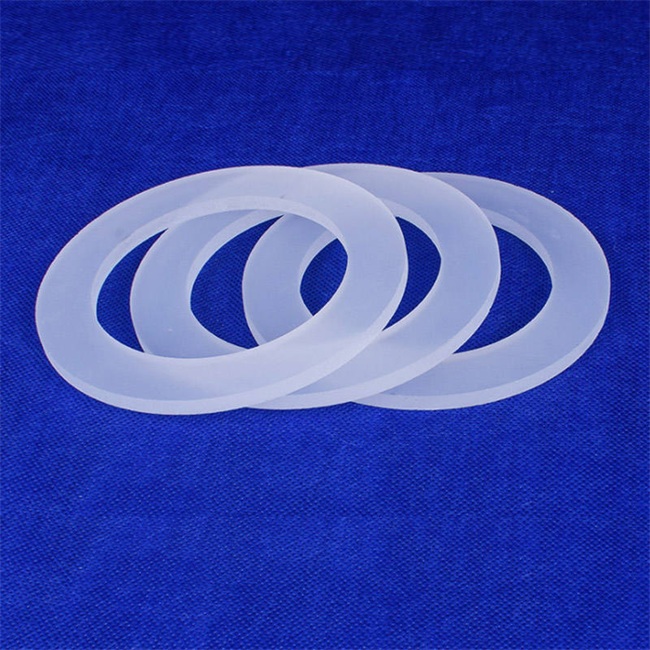

-Structural forms: flat flange, flange flange, blind flange, window flange and other designs

Material grade selection

-Transparent quartz glass: JGS1, JGS2, JGS3 grades, meeting different spectral requirements

-Opaque quartz: suitable for insulation or structural support parts

-Doped quartz: can add elements such as titanium and cerium to adjust specific properties

Surface treatment and accessories

-Precision polishing, sanding, coating and other surface treatments

-Provide a complete connection system including quartz bolts, washers, etc

-Can integrate temperature and pressure sensor installation interfaces

The core problem solved by quartz flange

1. High temperature connection sealing problem: In the temperature range where traditional metal flanges fail, quartz flanges provide a stable and reliable sealing solution.

2. Pollution sensitive environmental requirements: Avoid metal ion pollution and maintain the purity of the process environment.

3. Corrosive medium transportation: Replace metal and ordinary ceramic flanges in strong acid and alkali environments to extend equipment life.

4. Optical and observation requirements: To achieve real-time observation and monitoring in high temperature or corrosive environments.

5. Thermal expansion matching problem: Perfectly match with components such as quartz tubes and quartz reactors to avoid thermal stress rupture.

Why choose us as your quartz flange supplier

Professional focus: For 20 years, we have been dedicated to the research and manufacturing of quartz products, with 85% of our products exported to high-end markets in Europe, America, and Japan.

Technical strength: We have independent melting, CNC hot forming, and precision annealing production lines, which can control internal stress<5nm/cm.

Customization capability: Independently complete the entire process from drawings to finished products, with fast delivery.

Global Service: Products are sold worldwide.

Application case sharing

1. European semiconductor equipment manufacturer: Customized a Φ 450mm CF flange for their new MOCVD equipment, requiring a flatness of<0.02mm and a surface roughness Ra of<0.4 μ m. We have solved the deformation problem of large-sized flanges through a special annealing process, and the product has been running stably for 18 months.

2. Japan Photovoltaic Research Institute: We need a special connecting flange that can work under 1500 ℃ cyclic thermal shock. We have developed a titanium doped quartz formula to increase the temperature difference for thermal shock resistance from 800 ℃ to 1100 ℃, with extremely high customer satisfaction.

3. American chemical companies: For pipeline systems transporting high-purity hydrofluoric acid, the original PTFE flange had a lifespan of only 3-6 months. Our designed thick walled quartz flange has been continuously used for over 3 years, significantly reducing maintenance costs.

4. China Laser Laboratory: We need a window flange that meets both high vacuum (10 ⁻⁷ Pa) and 266nm deep ultraviolet laser transmission requirements. We use JGS1 material and special sealing technology to achieve performance indicators better than customer requirements.

We not only sell products, but also provide you with a complete quartz connection solution. From technical consultation, design support to installation guidance, we accompany you throughout the entire process to ensure the success of your project.

Do you have specific requirements for quartz flanges? Welcome to submit your technical parameters or design drawings. Our engineers will provide customized solutions and detailed quotations within 24 hours. Click to contact us and embark on your journey of high-performance quartz solutions!

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.