T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

Why is it recommended to use quartz plates in the field of optics

Q: In optical system design, I need a material that can ensure high transparency, high temperature resistance, thermal shock resistance, and dimensional stability, while also being able to customize complex shapes. What recommendations do you have?

Answer: Customizing fossil quartz plates is exactly the solution you need - it can provide a wide spectrum of high transmittance from ultraviolet to infrared, maintain optical stability under high temperature and severe temperature differences, and can achieve your exclusive design needs through precision machining, directly improving the performance and durability of the optical system.

The rapid development of optical technology has put forward higher requirements for material properties. Among numerous optical materials, quartz plates (quartz glass plates) have become a key material in optical system design due to their unique physical and chemical properties.

The core application of quartz plates in the field of optics

Quartz plates are made of high-purity silicon dioxide (SiO ₂) and are widely used in the following optical scenarios:

-Laser optical system: used for laser generator windows, reflector substrates, beam extenders, and focusing lenses, especially indispensable in ultraviolet lasers and high-power laser equipment.

-Spectral analysis instrument: As the window plate, colorimetric dish, and prism material of the spectrometer, it ensures the wide spectral range of light transmission performance from ultraviolet to infrared.

-Optical lenses and lenses: lens components used in high-end cameras, microscopes, telescopes, and projection systems, especially in environments that require low thermal expansion coefficients.

-Photomask substrate: used as a mask substrate in semiconductor lithography processes to ensure precise transfer of micro circuit patterns.

-UV optical device: used for UV curing, UV disinfection, and UV analysis equipment, leveraging its high transmittance advantage in the UV band.

-Optical windows and observation windows: Optical observation windows used in high temperature, high pressure, or corrosive environments, such as spacecraft portholes, special reaction vessel sight glasses, etc.

Performance advantages and key characteristics of quartz plates

1. Excellent optical performance

-Wide spectral range and high transmittance: maintaining high transmittance from ultraviolet (about 170nm) to infrared (about 2600nm), especially in the ultraviolet region, the performance far exceeds that of ordinary optical glass.

-Low self luminescence: Almost no spontaneous fluorescence is generated under UV or radiation irradiation, ensuring the purity of optical signals.

-High uniformity: The refractive index distribution is uniform, ensuring the imaging quality of the optical system.

2. Excellent physical and chemical stability

-Extremely low coefficient of thermal expansion (about 5.5 × 10 ⁻⁷/℃): minimal deformation during temperature changes, ensuring the stability of the optical system in variable temperature environments.

-High heat resistance: softening point up to 1730 ℃, long-term use temperature up to 1100 ℃.

-Chemical inertness: Acid resistant (except hydrofluoric acid and hot phosphoric acid), resistant to organic solvents, suitable for harsh chemical environments.

-High hardness and wear resistance: Mohs hardness level 7, the surface is not easily scratched.

3. Mechanical and electrical performance

-High rigidity: The elastic modulus is about 72GPa, and the supporting structure is stable.

-Excellent electrical insulation: high resistivity, low dielectric loss, suitable for optoelectronic devices.

Key issues in the field of optics solved by quartz plates

1. Material bottleneck of UV system: Ordinary optical glass strongly absorbs UV light, while quartz plate provides an ideal solution for UV transmission.

2. Thermal stability challenge: In high-energy optical systems such as lasers, material thermal deformation can cause optical path deviation. The low thermal expansion characteristics of quartz plates effectively maintain system stability.

3. Difficulties in adapting to harsh environments: In extreme environments such as aerospace and chemical engineering, the high temperature resistance and corrosion resistance of quartz plates ensure the reliable operation of optical systems.

4. High precision optical processing requirements: Quartz plates can achieve sub nanometer level surface roughness through precision polishing, meeting extremely high precision optical surface requirements.

5. Long term stability requirements: Quartz material does not absorb moisture, does not deteriorate, and its performance does not change over time, ensuring the long-term accuracy of optical instruments.

Why choose our quartz plate products

As a professional manufacturer of quartz products, we provide the following values to global optical customers:

1. Material purity and quality control

-Using high-purity quartz sand raw materials with a purity of 99.99% or higher

-Non polluting production environment throughout the entire process, avoiding metal ion pollution

-Perform spectral analysis on each batch of products to ensure optical consistency

2. Precision machining capability

-Capable of processing quartz plates with a thickness ranging from 0.1mm to 100mm

-The highest surface accuracy can reach λ/20 (@ 632.8nm)

-Multiple surface treatment options: polishing, coating, etching, etc

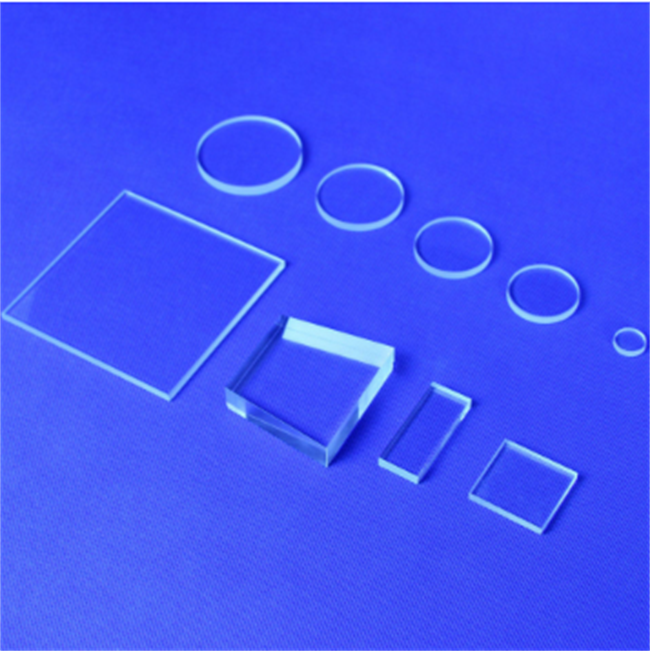

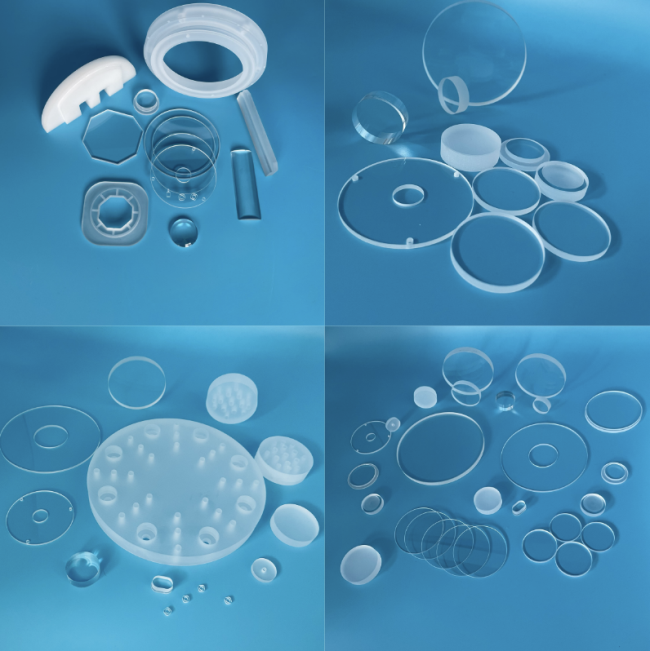

-Customizable in various shapes and sizes, with a maximum processing size of 1200 × 800mm

3. Special quartz plate product line

-UV grade quartz plate: optimizing UV transmission performance

-Laser grade quartz plate: low inclusion, low defect density, suitable for high-power laser applications

-Low self luminous quartz plate: special process reduces fluorescence background

-Anti radiation quartz plate: processed to reduce color centers caused by radiation

4. Professional optical application support

-Provide optical design consultation and material selection suggestions

-Recommend the best quartz plate type based on application scenarios

-The technical support team has a background in optical engineering

Customer Application Case (Anonymous)

1. European laser equipment manufacturer: Using our laser grade quartz plate as the output window of the 10kW fiber laser, it can operate continuously for 2 years without thermal deformation problems, and the power stability remains within ± 0.5%.

2. American semiconductor equipment company: Using our low defect quartz plate as the mask substrate for deep ultraviolet lithography, the defect density is less than 0.05/cm ⊃2;, significantly improving chip yield.

3. Japanese analytical instrument company: We use our UV grade quartz plate as the sample chamber window in their high-end UV spectrophotometer, which increases the transmittance to 92% at 200nm and the detection sensitivity by 30%.

4. Aerospace Research Institute: Our anti radiation quartz plate is selected as the satellite optical observation window, which can withstand extreme temperature changes and radiation environments during in orbit operation and maintain stable performance.

5. Australian University Laboratory: Using our low self luminous quartz plate to build a single photon detection system, the background noise is reduced to 1/5 of the original, significantly improving the signal-to-noise ratio.

With the continuous development of optical technology towards higher precision, wider spectral range, and more demanding environmental applications, the importance of quartz plates as an excellent optical material is becoming increasingly prominent. Choosing high-quality quartz plates correctly and applying them reasonably in optical systems can significantly improve equipment performance, extend service life, and reduce maintenance costs.

What material related challenges or issues have you encountered in the design or use of your optical products? Welcome to leave a message and communicate with us. Our professional technical team will provide you with targeted suggestions.

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.