T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

Q: How to choose materials that can withstand high temperatures and ensure chemical stability in the laboratory?

Answer: Quartz plates are an ideal choice for laboratory high-temperature reactions, corrosive experiments, and precision optical instruments due to their high purity, high temperature resistance, and extremely strong chemical inertness.

Q: How to avoid impurity contamination or thermal deformation in experiments?

Answer: The thermal expansion coefficient of quartz plate is extremely low, and it hardly deforms at high temperatures. The surface is smooth and dense, and it is not easy to attach pollutants, ensuring the accuracy and repeatability of experimental results.

Q: How to quickly meet customized needs?

Answer: We provide customized services such as flexible size, shape, thickness, and perforation, supporting global rapid prototyping and delivery, and adapting to various instrument and equipment integration needs.

In the fields of scientific research experiments, industrial testing, and high-tech manufacturing, the choice of materials directly affects the accuracy of results and the stability of processes. Quartz plate, as a high-performance laboratory material, is increasingly becoming a standard configuration in high-end laboratories.

Quartz plate is a special type of glass made of silicon dioxide, which has an extremely low coefficient of thermal expansion, excellent high temperature resistance, good chemical stability, and high transmittance. It is widely used in fields such as semiconductors, optical communications, precision instruments, and optical coatings, and is an important foundational material for high-end industry and scientific research.

Core advantages and characteristics of quartz plate

Quartz plates are made of high-purity silicon dioxide (SiO ₂), and their unique physical and chemical properties make them excellent in laboratory environments:

-Ultimate thermal stability: Quartz plates have an extremely low coefficient of thermal expansion and can withstand prolonged high temperatures (up to 1100 ℃) without deformation or cracking, making them suitable for high-temperature reactions, sintering, and heat treatment scenarios.

-Excellent optical transmittance: Especially in the ultraviolet (UV) band, quartz plates have significantly better transmittance than ordinary glass, making them an ideal window material for UV spectroscopic analysis, photochemical reactions, and optical detection.

-Excellent corrosion resistance: In addition to hydrofluoric acid and hot phosphoric acid, quartz plates exhibit strong resistance to most acids, bases, and organic solvents, making them suitable for experimental operations in highly corrosive environments.

-High purity and low pollution risk: High purity quartz material hardly precipitates impurities, avoiding sample contamination and ensuring the accuracy of analysis results.

-Excellent electrical insulation: able to maintain good insulation performance at high temperatures, suitable for semiconductor, electronic component testing and other scenarios.

Key application scenarios of quartz plates in laboratories

1. High temperature experimental platform: As a high-temperature furnace observation window, heating plate liner, or sample carrier plate, it provides stable support in material sintering, crystal growth, and thermal analysis.

2. Spectral analysis window: an optical window used for UV visible spectrophotometers, infrared spectrometers, and laser experiments to ensure the authenticity and reliability of spectral data.

3. Microelectronics and semiconductor manufacturing: As a wafer carrier, etching mask, or vacuum chamber observation window, it maintains high stability in a clean environment.

4. Chemical synthesis and corrosion experiments: As a lining for reaction vessels or a platform for handling corrosive substances, it can resist chemical corrosion and extend equipment life.

5. Life science research: Provide biocompatible and highly transparent solutions in scenarios such as cell culture observation and fluorescence microscope slides.

What common laboratory problems can quartz plates solve?

-Eliminating experimental errors caused by thermal deformation: Ordinary glass or ceramic materials are prone to deformation when temperature changes, which affects the position and optical path of the sample. The low thermal expansion characteristics of quartz plates ensure dimensional stability at high temperatures.

-Avoid data distortion caused by UV absorption: Ordinary glass strongly absorbs UV light, which interferes with UV spectral measurements. The high ultraviolet transmittance of quartz plates ensures the accuracy of data in the short wavelength region.

-Reduce pollution risk: Low purity materials may precipitate metal ions and contaminate samples in high temperature or corrosive environments. High purity quartz (with a purity of over 99.99%) greatly reduces the possibility of contamination.

-Extending the lifespan of experimental components: In harsh environments, the corrosion and heat resistance of quartz plates significantly reduce the frequency of replacement and lower long-term operating costs.

-Improving experimental safety: The high strength and high heat resistance of quartz plates reduce the risk of rupture during the experimental process, protecting personnel and equipment safety.

Customized services: meet the diverse needs of laboratories worldwide

As a professional quartz product manufacturer, we provide comprehensive customized services to ensure that each quartz plate is perfectly adapted to your experimental system:

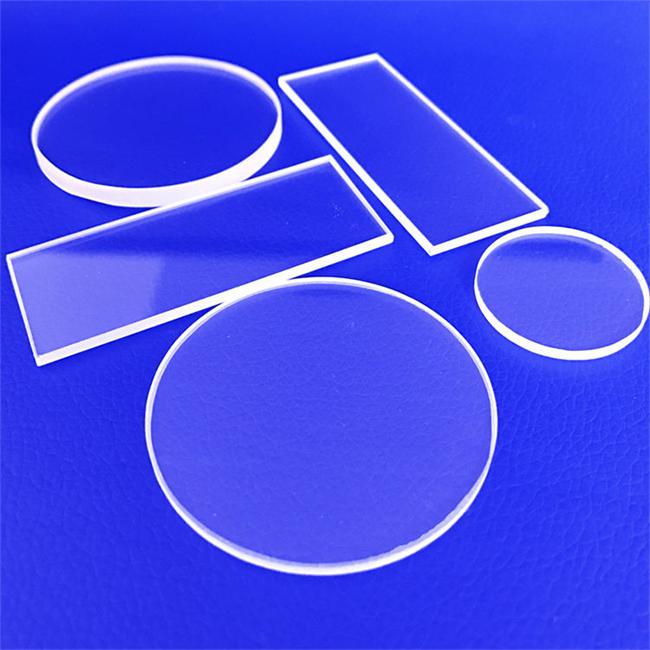

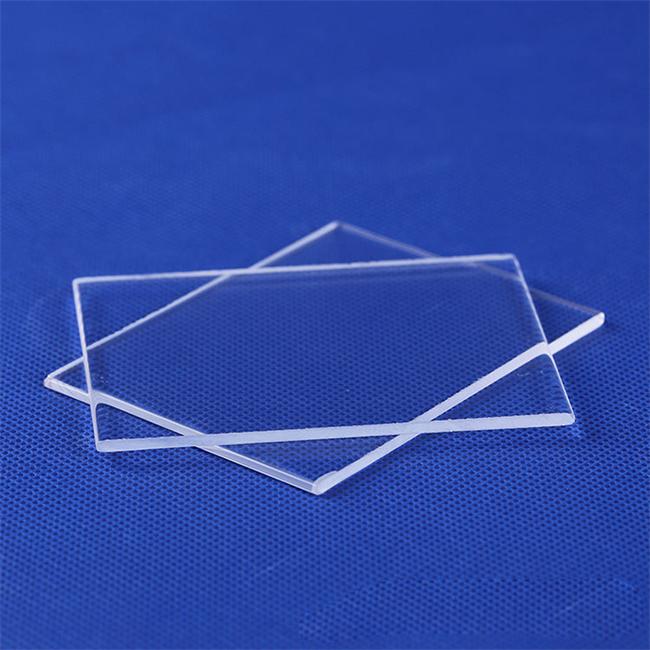

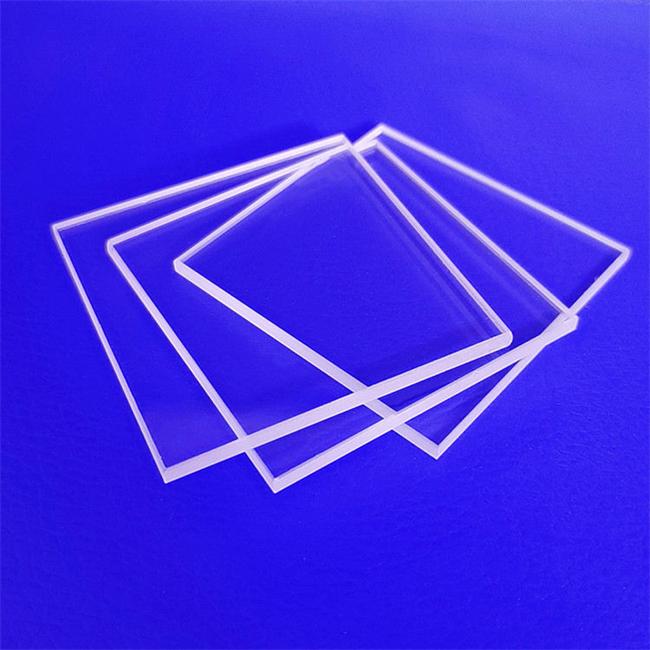

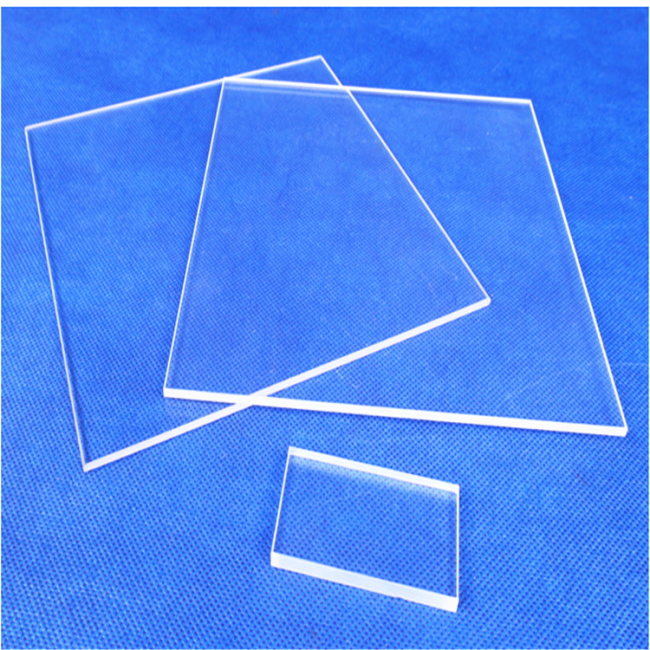

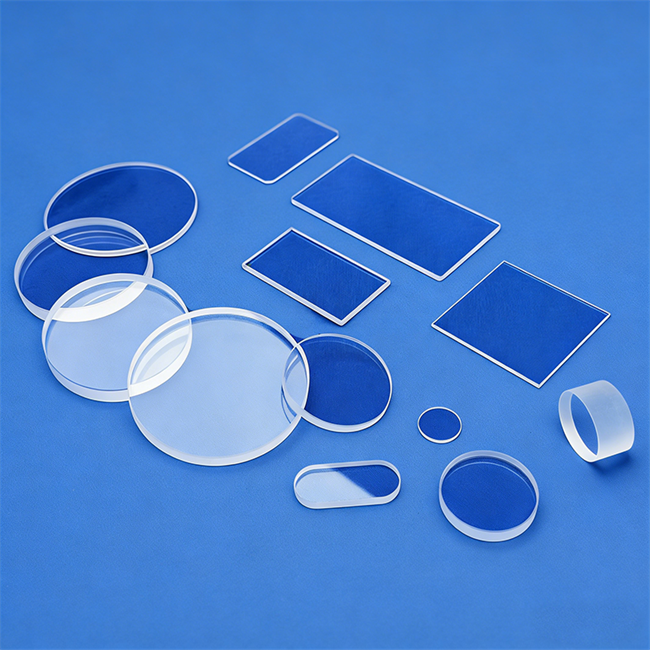

-Customization of Size and Shape: We offer circular, rectangular, and irregular cutting options with thicknesses ranging from 0.5mm to 50mm. The maximum size can reach 600 × 600mm and we support non-standard designs.

-Surface processing: Provides surface treatment processes such as polishing (single-sided/double-sided), sanding, and coating (anti reflective film, reflective film, conductive film, etc.).

-Aperture and edge processing: It can process various apertures, slots, chamfers, and edge strengthening treatments to meet the integration requirements of complex experimental devices.

-Purity grade selection: We provide quartz materials with different purity grades (standard grade, high-purity grade, ultra-high purity grade) to meet different experimental accuracy requirements.

Why choose us as your quartz plate supplier?

1. Professional technical accumulation: Focusing on the production of quartz products for 15 years, mastering the full chain technology from raw material screening to precision processing, ensuring product performance consistency.

2. Global service experience: Providing products to laboratories and research institutions in over 30 countries including Europe, America, Japan, South Korea, Australia, etc., and understanding the standards and needs of different regions.

3. Strict quality control: Each process has inspection nodes, and key parameters (flatness, parallelism, transmittance) are tested using advanced instruments with a tolerance control of ± 0.2mm.

4. Rapid response capability: Standard size products can be delivered within 7-15 days, customized products can be delivered within 3-4 weeks, and expedited service options are provided.

5. Cost optimization plan: By optimizing production processes and large-scale procurement, we provide competitive prices while ensuring quality.

6. Full process technical support: From design consultation to installation guidance, a professional technical team provides full process support to ensure that the product is perfectly adapted to your application.

Application case sharing (anonymous customer)

Case 1: European Materials Research Institute High Temperature Observation System

The customer needs to observe the material phase transition process in real-time at 1400 ℃. Our double-sided polished quartz observation window (diameter 200mm, thickness 8mm) has successfully solved the problems of thermal deformation and decreased transmittance of traditional glass windows, improving the continuity of experimental data acquisition by 90%.

Case 2: Fluorescence Analysis Platform of North American Biotechnology Company

The customer's original glass slide produces background fluorescence under UV excitation, which interferes with weak signal detection. Our customized UV grade quartz carrier (75 × 25 × 1mm, double-sided optical polishing) reduces background noise to 1/5 of its original level, significantly improving detection sensitivity.

Case 3: Etching Process Improvement of Asian Semiconductor Enterprises

The customer requires an observation window that is resistant to hydrofluoric acid vapor during the chip etching process. The coated protective quartz observation window we developed extends its service life from the original 2 months to 18 months while ensuring visibility, saving approximately $60000 in maintenance costs annually.

Quartz plates are not only a material choice for laboratories, but also a key factor in improving experimental accuracy, ensuring data reliability, and reducing long-term operating costs. With the continuous improvement of scientific research and industrial testing standards, high-performance quartz products are becoming an essential element in advanced laboratories.

Do you need a customized quartz solution for your laboratory?

Welcome to contact our technical team and provide your specific needs (application scenarios, size specifications, performance requirements, etc.). We will provide you with free product selection suggestions and customized solutions. Global shipping and technical support ensure that you receive the most suitable quartz products for your experimental needs.

Consult now for customized services to enhance your experimental accuracy and efficiency with professional quartz plates!

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.