T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

Q: Why is material selection crucial in scientific research experiments?

A: The purity, thermal stability, and chemical inertness of materials directly affect the accuracy and reproducibility of experimental data.

Q: What core problems can quartz plates solve in scientific research?

A: Quartz plates, with their high purity, high temperature resistance, corrosion resistance, and excellent optical transmission performance, can solve deformation problems in high-temperature experiments, material degradation problems in strong corrosive environments, and signal interference problems in optical experiments.

Q: How can it improve research efficiency?

A: Customized sizes and specifications of quartz plates can perfectly adapt to various precision instruments, reducing experimental preparation time. At the same time, their long lifespan reduces the cost and interruption risk of frequent consumables replacement

In precision science experiments, the choice of materials directly affects the accuracy and reproducibility of research results. Quartz plates, with their excellent physical and chemical properties, have become an indispensable basic material in modern scientific research laboratories. As a professional manufacturer of customized quartz products, we provide high-quality quartz plate solutions to global research institutions, helping scientific research break through boundaries.

The outstanding characteristics and product advantages of quartz plates

1. Ultra high purity and chemical stability

-Purity of over 99.99%, ensuring no metal ion contamination

-Resistant to strong acid and alkali corrosion (excluding hydrofluoric acid)

-Maintain chemical inertness at high temperatures

2. Excellent optical performance

-Wide transmission range (170nm-2500nm), covering the ultraviolet to infrared bands

-Low self fluorescence background, reducing optical interference

-High transmittance (>90% at 200nm)

3. Thermal stability and mechanical strength

-Extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃)

-Strong heat shock resistance (maximum operating temperature of 1100 ℃)

-High surface hardness (Mohs 7), wear-resistant and scratch resistant

4. Electrical and radiation properties

-Excellent electrical insulation

-Strong radiation resistance

-Low dielectric loss

Research application scenarios and problem solutions

1. Spectral analysis field

-Application scenarios: UV visible spectrophotometer sample cell, Fourier transform infrared spectrometer window

-Solution: Eliminate the absorption interference of ordinary glass in the ultraviolet region to ensure the accuracy of spectral data

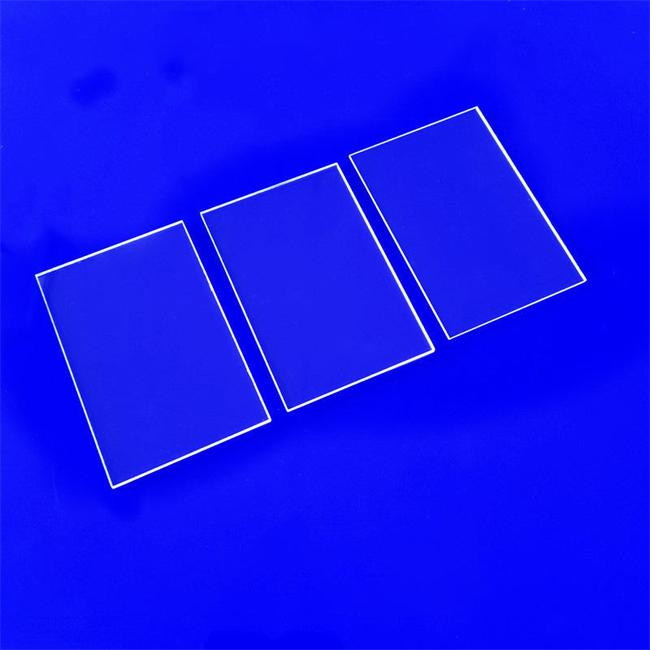

-Recommended specifications: 1-5mm thickness, double-sided optical polishing, flatness λ/10

2. Microfluidic chip technology

-Application scenarios: Microfluidic chip substrates, microreactors

-Problem solving: Provide excellent chemical compatibility and optical transparency for real-time observation

-Recommended specifications: 0.5-2mm thickness, precision etching processing, surface roughness Ra<10nm

3. High temperature experimental apparatus

-Application scenarios: Tube furnace observation window, high-temperature reactor window

-Problem solving: Tolerate extreme temperature changes without cracking, maintain clear observation

-Recommended specifications: 3-10mm thickness, high temperature resistant coating treatment

4. Semiconductor and Optoelectronic Research

-Application scenarios: Photolithography mask templates, wafer carriers

-Problem solving: Low thermal expansion ensures dimensional stability, high purity avoids contamination

-Recommended specifications: Precision photolithography processing, surface flatness<1 μ m

5. Life science research

-Application scenarios: Cell culture observation plates, fluorescence microscope slides

-Problem solving: No biological toxicity, low spontaneous fluorescence, improved imaging signal-to-noise ratio

-Recommended specifications: Biocompatibility treatment, ultra clean packaging

Comprehensive customized services to meet the diverse needs of scientific research

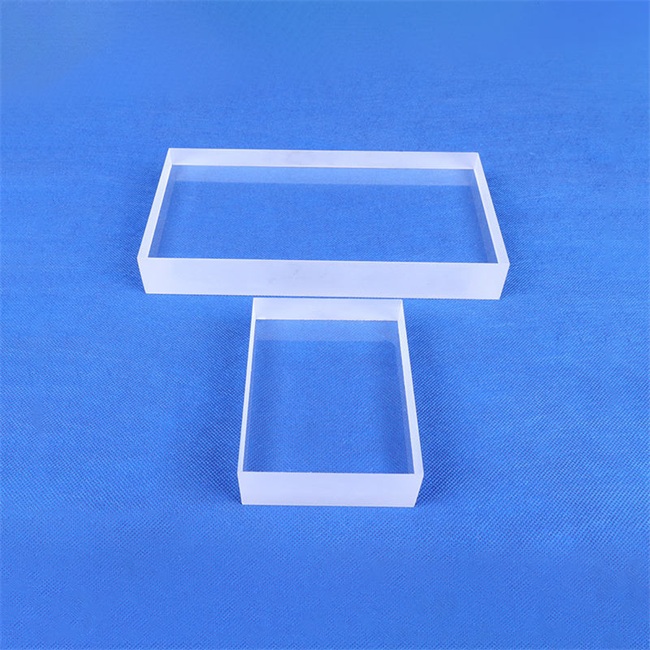

1. Customization of size and shape

-Thickness range: 0.1mm to 50mm

-Maximum size: up to 500 × 600mm

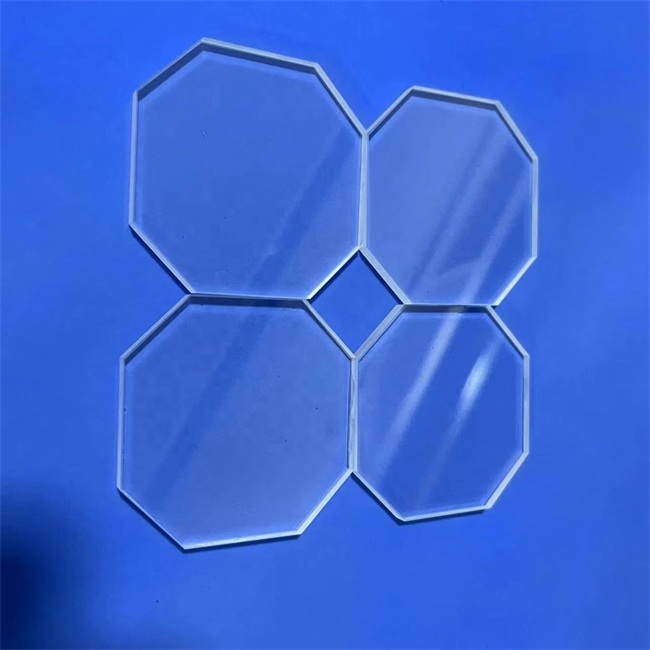

-Alien cutting: Round, square, and special contours can be customized

-Chamfering and Edge Treatment: Protecting the Safety of Researchers

2. Surface treatment process

-Optical grade polishing: achieving λ/20 flatness

-Double sided or single-sided polishing options

-Coating services: anti reflective film, reflective film, high-temperature resistant film

-Special texture processing: increase cell adhesion, etc

3. Control of machining accuracy

-Dimensional tolerance: ± 0.01mm to ± 0.1mm optional

-Parallelism: up to 10 arc seconds

-Surface quality: 10/5 scratch and pitting standard or higher

4. Material grade selection

-Optical grade quartz: JGS1, JGS2, JGS3

-Fused silica: HPFS ® 7980, Corning 7980

-Synthetic quartz: extremely low metal impurity content

Why Choose Us: Core Advantages of Professional Manufacturers

1. 20 years of experience, global service network

-Products exported to 35+countries and regions

-Multi language technical support (English, German, Japanese, etc.)

-Familiar with research equipment standards and specifications from various countries

2. Whole process quality control system

-Raw material traceability: cooperation with top global quartz sand suppliers

-Production monitoring: real-time detection of each process

3. Flexible production capacity

-Support small-scale trial production to large-scale production

-Quick response: Standard products can be delivered within 7-14 days

-Special channel for urgent orders

4. Comprehensive after-sales support

-Application technical support

-Product usage guide

-Long term quality tracking

Application Case (Anonymous Display)

Case 1: Top European Physics Research Institute

-Requirement: Radiation detection window for Large Hadron Collider experiments

-Challenge: To withstand high-energy particle radiation while maintaining optical performance

-Solution: Customized 200 × 300mm synthetic quartz plate with a thickness of 8mm and special annealing treatment

-Result: Continuous operation for 3 years without performance degradation, highly praised by the research team

Case 2: North American Biomedical Laboratory

-Requirement: Ultra low fluorescence background glass slides for long-term observation of live cells

-Challenge: Reduce spontaneous fluorescence and improve single-molecule detection sensitivity

-Solution: High purity synthetic quartz, thickness 1mm, double-sided λ/4 polishing

-Result: Fluorescence background decreased by 60%, and the quality of experimental data significantly improved

Case 3: Asian Semiconductor Research Center

-Requirement: Mask substrate for extreme ultraviolet lithography technology

-Challenge: Nano level surface smoothness and thermal stability

-Solution: JGS1 quartz, flatness<0.5 μ m, precise control of thermal expansion coefficient

-Result: The lithography accuracy has been improved to meet the 7nm node requirement

Case 4: Australian Marine Research Institution

-Requirement: Deep sea exploration equipment pressure resistant observation window

-Challenge: Tolerate pressure at a depth of 1000 meters and seawater corrosion

-Solution: Half spherical quartz observation window, thickness 25mm, edge strengthening treatment

-Result: Successfully deployed for 12 months without any malfunctions, obtaining valuable deep-sea data

Whether you are conducting basic scientific research or developing applied technologies, choosing the right quartz material is the key to success. We invite you to contact us to discuss your specific needs. Our technical team will provide you with professional material selection advice and customized solutions to help your research project overcome technical bottlenecks.

Consult now for free samples or technical solution evaluations, making professionally customized quartz plates your reliable partner for scientific breakthroughs!

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.