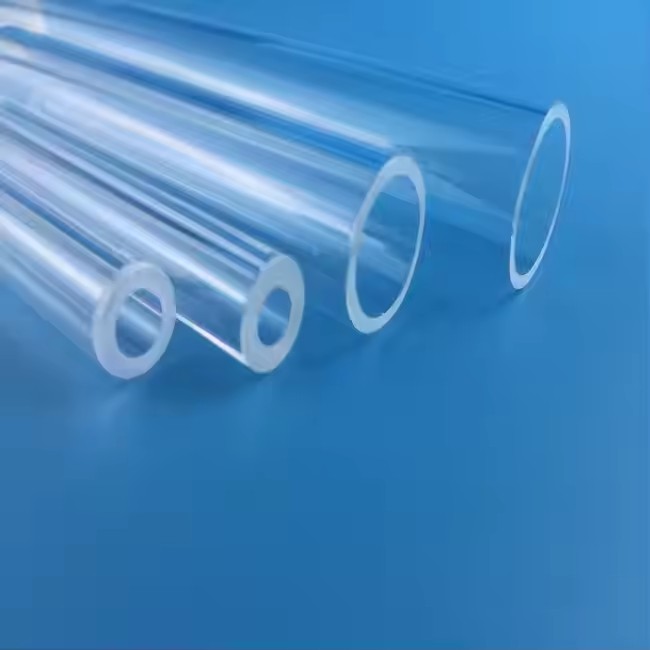

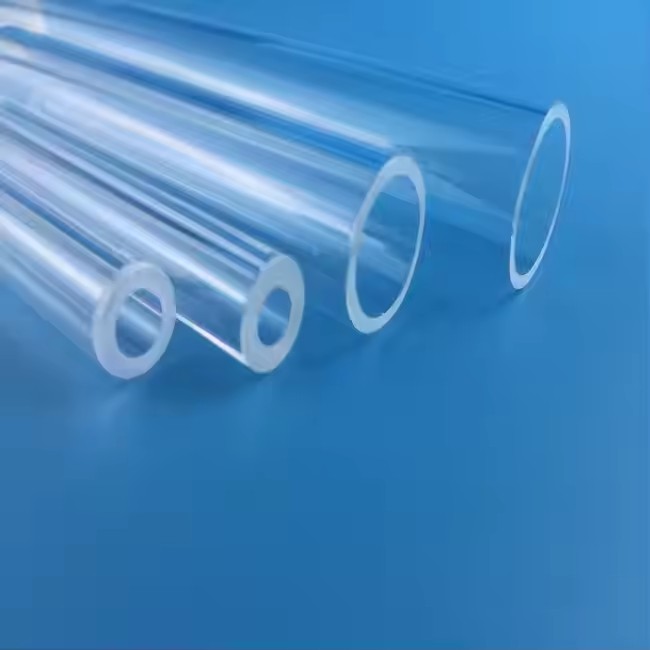

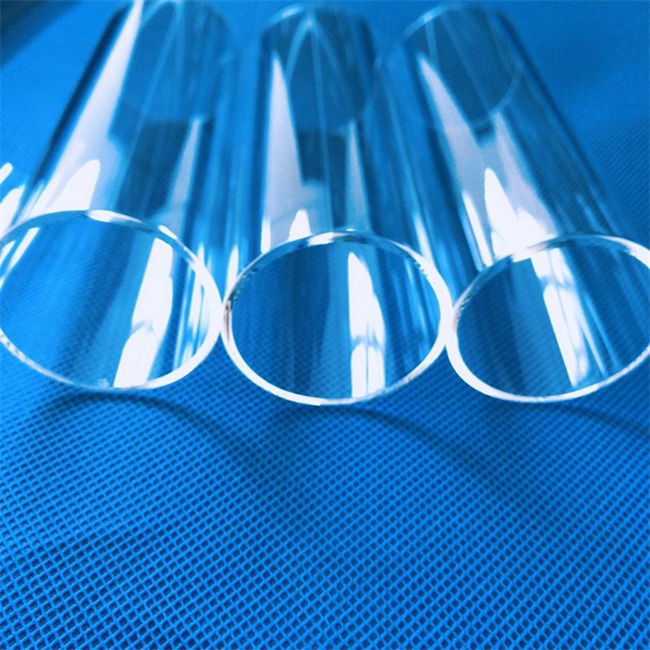

1-50mm high-purity semiconductor quartz tube, made of high-purity quartz material, with a purity of over 99.99%, high temperature resistance, corrosion resistance, and excellent thermal stability. Suitable for semiconductor manufacturing, photovoltaics and other fields, meeting high-temperature process requirements and ensuring pure and pollution-free production processes.

As a manufacturer specializing in the research and production of high-end quartz products, we are committed to providing high-purity, high-precision, and high-performance quartz tube products to customers in the global semiconductor, optoelectronic, and scientific research fields.

Core advantages of the product

Our semiconductor quartz tube is made of natural high-purity quartz sand, manufactured through advanced vacuum melting technology and precision control technology, and has the following significant advantages:

-Ultra high purity: SiO ₂ content ≥ 99.99%, key metal impurities (such as K, Na, Li, Fe) content less than 1ppm, meeting the stringent requirements of semiconductor processes for materials.

-Excellent thermal stability: The softening point is as high as 1730 ℃, and it can work stably for a long time at a high temperature of 1200 ℃. The coefficient of thermal expansion is extremely low (5.5 × 10 ⁻⁷/℃), and it has strong thermal shock resistance.

-Excellent optical performance: It has high transparency in the ultraviolet to infrared wavelength range (especially in the deep ultraviolet region), meeting the requirements of photolithography, detection and other processes.

-Precision dimension control: The diameter range is 1-50mm, and the tolerances for wall thickness, concentricity, and straightness can be controlled within ± 0.05mm to ensure process consistency.

-Excellent surface quality: The inner and outer surfaces are finely polished, without bubbles or particle contamination, suitable for clean room environments.

Main application areas

This product is designed specifically for high-tech industries and is mainly used for:

-Semiconductor manufacturing: diffusion furnace tubes, oxidation furnace tubes, CVD reaction tubes, carrier boats, etc.

-Optoelectronic industry: LED/MOCVD equipment tubes, photovoltaic coating furnace tubes, laser device protective sleeves.

-Research experiment: High temperature reaction vessel, optical experimental device, analytical instrument accessories.

-High end lighting: halogen lamps, ultraviolet lamps, special light source tubes.

The key problems we can solve

In semiconductor and high-end manufacturing, material defects often lead to serious consequences. Our quartz tube can effectively solve the following common problems:

1. Pollution risk: Low metal impurity content avoids contamination of wafers and improves chip yield.

2. High temperature deformation: Excellent thermal stability ensures dimensional stability in high-temperature processes and extends component life.

3. Process fluctuation: Precise dimensional control ensures uniform gas flow field and improves process repeatability.

4. Cost escalation: High durability reduces downtime and replacement frequency, lowering overall operating costs.

Our customized services

We provide deeply customized solutions to meet diverse needs:

-Size customization: Supports non-standard diameters, wall thicknesses, lengths, and special conical/irregular designs.

-Purity level: Different purity levels (such as 99.99%~99.999%) can be provided according to process requirements.

-Surface treatment: Provide inner wall coating, outer wall sanding, flame polishing and other treatments.

-Certification support: Material reports, size inspection reports, cleanliness testing data, etc. can be provided.

-Quick response: Sample delivery time is 7-15 days, production orders take 4-6 weeks, and urgent needs can be expedited.

Why choose us?

-Focused on foreign trade for 20 years: Deeply cultivating the global market, exporting products to more than 30 countries and regions including Europe, America, Japan, South Korea, Southeast Asia, etc., familiar with international standards and customer needs.

-Technical team support: A team of engineers with over 10 years of experience can provide application selection and problem diagnosis.

-Cost effectiveness advantage: With our own production base and no intermediate links, we offer more competitive prices for the same quality.

-Sustainable cooperation: providing long-term supply guarantee, technological upgrade support, and regular quality tracking.

Customer Case (Anonymous)

-Case 1: A semiconductor equipment manufacturer in South Korea purchases Ø 30mm high-purity quartz tubes for CVD equipment. The original supplier's product had a problem with microbubbles, but we optimized the melting process to provide bubble free products, helping customers reduce equipment failure rates by 40%.

-Case 2: A photovoltaic research institute in Germany customized Ø 12mm thin-walled quartz tubes for experiments on new perovskite cells. We provide precision cutting and flame sealing services to meet their small batch and multi batch research and development needs, and help their projects obtain EU funding support.

-Case 3: A certain LED company in the United States has been purchasing Ø 50mm quartz tubes for long-term use in MOCVD reaction chambers. We have reduced the transportation damage rate from 3% to 0.2% and saved over $50000 in annual costs by improving packaging and logistics solutions.

In the high-tech field that pursues precision and reliability, the choice of materials directly determines the success or failure of the process. Our 1-50mm high-purity semiconductor quartz tubes have become a trusted partner for global customers due to their excellent purity, stable performance, and precise manufacturing.

If you are looking for high-purity quartz tube suppliers or have any questions about technical parameters or application scenarios, please feel free to contact us at any time.

Luverre Quartz can manufacture customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.