T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

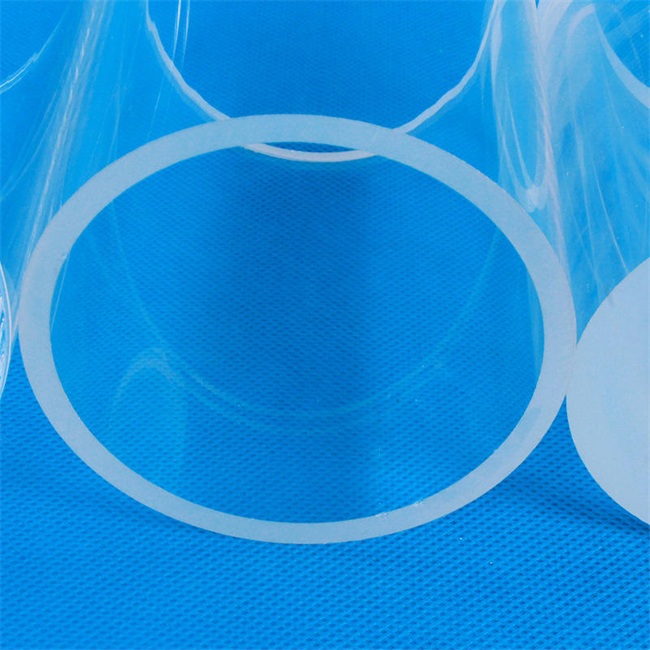

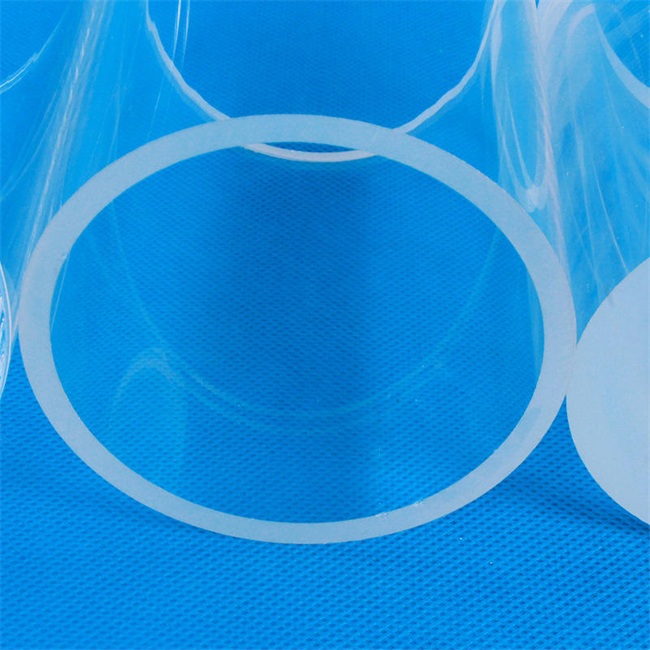

High temperature resistant quartz glass furnace tube

High temperature resistant quartz glass furnace tube is a key industrial element made of high-purity fused silica.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

High temperature resistant quartz glass furnace tube

High temperature resistant quartz glass furnace tube is a key industrial element made of high-purity fused silica. With its excellent thermal stability, excellent optical performance and excellent chemical purity, it is widely used in semiconductor, photovoltaic, new materials, laboratory research and other fields. This product is designed to achieve stable and reliable process in high temperature and corrosive environments.

Core product advantages: Why choose our quartz furnace tube?

Our high-temperature resistant quartz glass furnace tubes are not ordinary glass products, and their performance advantages stem from the characteristics of the material itself and precision manufacturing processes.

1. Excellent temperature resistance performance

Extremely high softening point: The softening point can reach up to 1730 ℃, with a long-term use temperature of 1200 ℃ and a short-term maximum tolerance temperature of 1450 ℃, ensuring no deformation or collapse in extreme high temperature environments.

Extremely low coefficient of thermal expansion: With a thermal expansion coefficient of only 5.5 × 10 ⁻⁷/℃, it has super strong thermal shock resistance and can withstand severe temperature changes (such as rapid heating and quenching), greatly reducing the risk of cracking due to thermal stress.

2. Excellent optical and physical properties

Hyperspectral transmittance: It has high transmittance in a wide spectral range from ultraviolet to infrared, especially suitable for processes that require ultraviolet curing, infrared heating, or optical monitoring.

Excellent electrical insulation: It can maintain good electrical insulation performance at high temperatures and is an ideal high-temperature insulation material.

High mechanical strength: Compared to ordinary glass, quartz glass has higher mechanical strength and longer service life.

3. Outstanding chemical stability

High purity and corrosion resistance: Made of over 99.99% high-purity silicon dioxide (SiO ₂), it hardly reacts with other acidic substances except hydrofluoric acid and hot phosphoric acid.

Strong pollution resistance: The inner wall is smooth and not easily attached to the sample. It will not react with the materials processed inside the tube (such as wafers, metals, chemicals) at high temperatures, effectively ensuring the purity of the process.

Main application areas: In which scenarios is it indispensable?

This product is a core consumable and component for multiple high-tech and scientific research fields.

Semiconductor industry: a tube furnace used for diffusion, oxidation, CVD (chemical vapor deposition), annealing and other processes, serving as the core reaction chamber for carrying silicon wafers and conducting high-temperature treatment.

Photovoltaic industry: As a key carrier tube in the heat treatment process of polycrystalline silicon, monocrystalline silicon ingots, and solar cells.

New material synthesis: used for the research and production of new materials such as carbon nanotubes, graphene, and compound semiconductors (such as GaN).

Analytical instruments and laboratories: As furnace tubes for muffle furnaces and vacuum atmosphere tube furnaces, they are widely used in material sintering, heat treatment, ashing analysis and other experiments in universities and research institutes.

Optoelectronics and Lighting: Shell tubes used for electric light source products such as metal halide lamps and ultraviolet lamps.

The key problems we can solve

Choosing our high-temperature resistant quartz furnace tube can effectively address and solve the following industry pain points:

Solution to high temperature deformation problem: Replace ordinary glass or metal pipes to avoid softening deformation under long-term high temperature, which may cause equipment damage or process failure.

Addressing pollution and purity issues: preventing contamination of expensive samples being processed (such as semiconductor wafers) due to impure furnace tube materials or the release of impurities at high temperatures, ensuring product yield.

Addressing the risk of thermal shock rupture: significantly reducing the probability of furnace tube cracking caused by thermal stress in process cycles that require rapid temperature rise and fall, improving production safety and equipment utilization.

Addressing the issue of process energy efficiency: Excellent optical transparency allows for efficient penetration of infrared heater energy, achieving fast and uniform heating and improving energy utilization efficiency.

Customized service: meet your unique needs

We are well aware that standard products cannot meet all application scenarios. Therefore, we provide comprehensive customization services to ensure that our products perfectly match your equipment and craftsmanship.

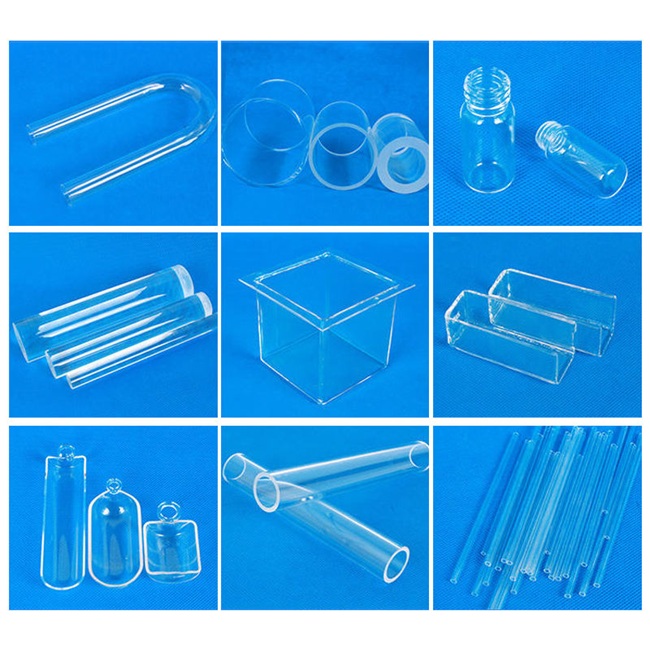

Size customization: The outer diameter, inner diameter, length, wall thickness, and other dimensions can be customized according to customer requirements.

Shape customization: supports the production of special shapes such as one end opening, two end opening, irregular ports, and flanges.

Function customization: It is possible to open holes on the pipe body, weld branch pipes, install observation windows, or perform special treatments such as sanding and coating.

This high-temperature resistant quartz glass furnace tube is a highly reliable product that has undergone strict quality control and performance verification, aiming to provide stable, pure, and durable solutions for the most demanding high-temperature application environments. We are committed to becoming your trusted partner in high-tech manufacturing and cutting-edge research fields through professional products and flexible customized services.

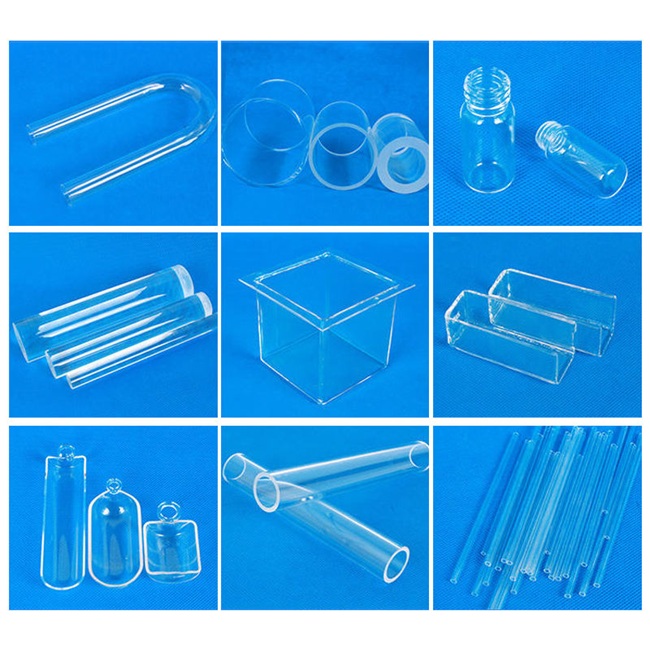

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.

High temperature resistant quartz glass furnace tube

High temperature resistant quartz glass furnace tube is a key industrial element made of high-purity fused silica. With its excellent thermal stability, excellent optical performance and excellent chemical purity, it is widely used in semiconductor, photovoltaic, new materials, laboratory research and other fields. This product is designed to achieve stable and reliable process in high temperature and corrosive environments.

Core product advantages: Why choose our quartz furnace tube?

Our high-temperature resistant quartz glass furnace tubes are not ordinary glass products, and their performance advantages stem from the characteristics of the material itself and precision manufacturing processes.

1. Excellent temperature resistance performance

Extremely high softening point: The softening point can reach up to 1730 ℃, with a long-term use temperature of 1200 ℃ and a short-term maximum tolerance temperature of 1450 ℃, ensuring no deformation or collapse in extreme high temperature environments.

Extremely low coefficient of thermal expansion: With a thermal expansion coefficient of only 5.5 × 10 ⁻⁷/℃, it has super strong thermal shock resistance and can withstand severe temperature changes (such as rapid heating and quenching), greatly reducing the risk of cracking due to thermal stress.

2. Excellent optical and physical properties

Hyperspectral transmittance: It has high transmittance in a wide spectral range from ultraviolet to infrared, especially suitable for processes that require ultraviolet curing, infrared heating, or optical monitoring.

Excellent electrical insulation: It can maintain good electrical insulation performance at high temperatures and is an ideal high-temperature insulation material.

High mechanical strength: Compared to ordinary glass, quartz glass has higher mechanical strength and longer service life.

3. Outstanding chemical stability

High purity and corrosion resistance: Made of over 99.99% high-purity silicon dioxide (SiO ₂), it hardly reacts with other acidic substances except hydrofluoric acid and hot phosphoric acid.

Strong pollution resistance: The inner wall is smooth and not easily attached to the sample. It will not react with the materials processed inside the tube (such as wafers, metals, chemicals) at high temperatures, effectively ensuring the purity of the process.

Main application areas: In which scenarios is it indispensable?

This product is a core consumable and component for multiple high-tech and scientific research fields.

Semiconductor industry: a tube furnace used for diffusion, oxidation, CVD (chemical vapor deposition), annealing and other processes, serving as the core reaction chamber for carrying silicon wafers and conducting high-temperature treatment.

Photovoltaic industry: As a key carrier tube in the heat treatment process of polycrystalline silicon, monocrystalline silicon ingots, and solar cells.

New material synthesis: used for the research and production of new materials such as carbon nanotubes, graphene, and compound semiconductors (such as GaN).

Analytical instruments and laboratories: As furnace tubes for muffle furnaces and vacuum atmosphere tube furnaces, they are widely used in material sintering, heat treatment, ashing analysis and other experiments in universities and research institutes.

Optoelectronics and Lighting: Shell tubes used for electric light source products such as metal halide lamps and ultraviolet lamps.

The key problems we can solve

Choosing our high-temperature resistant quartz furnace tube can effectively address and solve the following industry pain points:

Solution to high temperature deformation problem: Replace ordinary glass or metal pipes to avoid softening deformation under long-term high temperature, which may cause equipment damage or process failure.

Addressing pollution and purity issues: preventing contamination of expensive samples being processed (such as semiconductor wafers) due to impure furnace tube materials or the release of impurities at high temperatures, ensuring product yield.

Addressing the risk of thermal shock rupture: significantly reducing the probability of furnace tube cracking caused by thermal stress in process cycles that require rapid temperature rise and fall, improving production safety and equipment utilization.

Addressing the issue of process energy efficiency: Excellent optical transparency allows for efficient penetration of infrared heater energy, achieving fast and uniform heating and improving energy utilization efficiency.

Customized service: meet your unique needs

We are well aware that standard products cannot meet all application scenarios. Therefore, we provide comprehensive customization services to ensure that our products perfectly match your equipment and craftsmanship.

Size customization: The outer diameter, inner diameter, length, wall thickness, and other dimensions can be customized according to customer requirements.

Shape customization: supports the production of special shapes such as one end opening, two end opening, irregular ports, and flanges.

Function customization: It is possible to open holes on the pipe body, weld branch pipes, install observation windows, or perform special treatments such as sanding and coating.

This high-temperature resistant quartz glass furnace tube is a highly reliable product that has undergone strict quality control and performance verification, aiming to provide stable, pure, and durable solutions for the most demanding high-temperature application environments. We are committed to becoming your trusted partner in high-tech manufacturing and cutting-edge research fields through professional products and flexible customized services.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.