T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2023-08-17 Origin: Site

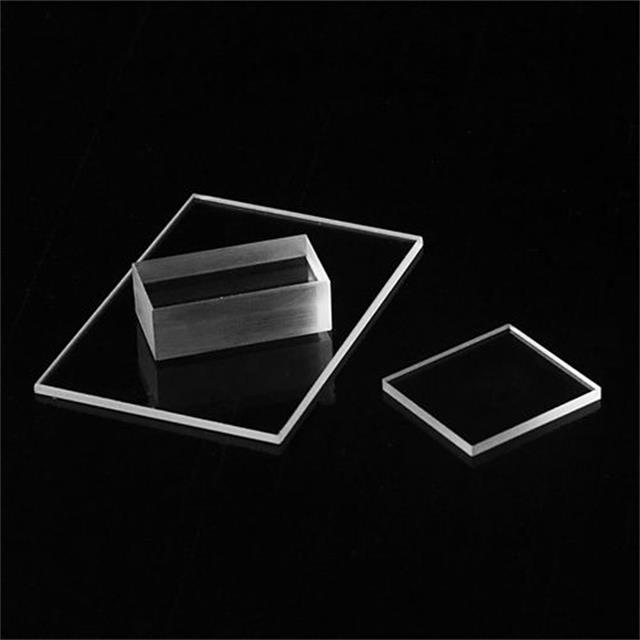

Quartz plate is usually smelted and cut from quartz, and their silica content can reach more than 99.99%. The hardness is Mohs seven, and it has the characteristics of high-temperature resistance, low thermal expansion coefficient, thermal shock resistance, and good electrical insulation performance. It is usually colorless and transparent, and the visible light transmittance is above 85%. Next, let's take a look at the performance and application fields of the quartz plate.

Here is the content list:

The unique performance of quartz plate.

The application field of quartz plates is very extensive.

Quartz plate because of its excellent characteristics. It is one of the indispensable excellent materials in modern cutting-edge technology such as space technology, atomic energy industry, national defense equipment, automation system, semiconductor, metallurgy, chemical industry, electric light source, communication, light industry, building materials, and other industries.

The appearance of the quartz plate is transparent, colorless, without bubbles, and traces of processing. In terms of purity, it is controlled at the order of PPM. It has an extremely low coefficient of thermal expansion, high-temperature resistance, excellent chemical stability, and excellent electrical insulation. It has a stable ultrasonic delay function, the best ultraviolet spectrum transmission performance, visible light and infrared spectrum performance, and higher mechanical properties than ordinary glass.

The optical function of the quartz plate has unique features. It cannot only pass through far-ultraviolet light, which is the best among all ultraviolet light materials but also passes through visible light and near-infrared spectrum. Because quartz glass is resistant to high temperatures, its thermal expansion coefficient is extremely small, its chemical stability is good, and its air bubbles, stripes, uniformity, and birefringence are comparable to ordinary optical glass. Therefore, it is an indispensable optical material with high stability optical coefficient working in various harsh occasions.

The formation of a quartz plate is the result of the high viscosity of its melt at high temperatures. It is used in the manufacture of semiconductors, electric light sources, semiconductor communication equipment, lasers, optical instruments, laboratory instruments, electrical equipment, medical equipment and high temperature and corrosion-resistant chemical instruments, chemical industry, electronics, metallurgy, building materials, and national defense industries.

Quartz plate has excellent optical performance, and also has the characteristics of thermal shock resistance, low thermal expansion coefficient, high-temperature resistance, good chemical stability, and good electrical insulation performance, so it has a wide range of applications. Such as semiconductor production, electric light source, semiconductor communication device, laser, optical instruments, laboratory instruments, electrical equipment, medical equipment and high temperature and corrosion resistant chemical instrument, chemical industry, electronics, metallurgy, building materials, and national defense and other industrial fields, and Printing and dyeing, plastics, food processing, medical and health industries. In addition, due to the high precision of the quartz plate, no bubbles, flat and smooth surface, corrosion resistance, and very good light transmission performance, the quartz plate is especially suitable for the fields of electron optics, military industry, and chemical industry.

After reading the above introduction, we can find that quartz plate is usually used in relatively harsh environments as a special function. Although it is not common in daily life, its value and significance are extraordinary. The above are the relevant answers I have summarized for you about the role of quartz plates. I hope it will be helpful to you. Our official website is https://www.luverrequartz.com/. To choose high-quality quartz plate materials, you must choose a factory with excellent technology.