T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

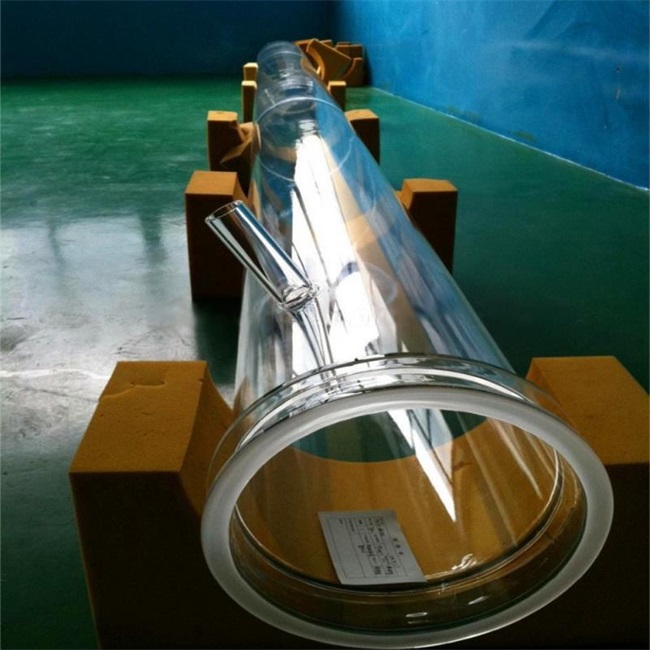

The quartz glass tube in the tube furnace is an important heating component, and its quality and condition directly affect the heating effect and operational stability of the equipment. Therefore, it is crucial to carry out meticulous daily maintenance on it. What are the daily maintenance measures for quartz glass tubes in tube furnaces?

1、 Temperature control

Understanding the softening point: The softening point of quartz glass tubes is about 1270 ℃, and the duration of use should be limited when approaching this temperature. Especially at 1200 ℃, the continuous use time should not exceed 3 hours to prevent the quartz tube from softening and deforming due to prolonged high temperature.

Avoid rapid temperature changes: During use, quartz glass tubes should be avoided from experiencing rapid temperature changes, such as rapid heating or cooling, which may cause the quartz tube to rupture due to thermal stress. Therefore, during the heating or cooling process, the temperature should be gradually adjusted to give the quartz tube enough time to adapt to temperature changes.

Natural cooling: After use, the tube furnace should be allowed to cool naturally, avoiding the use of rapid water addition or other rapid cooling methods to prevent quartz tube breakage due to excessive temperature changes.

2、 Gas usage safety

Restricting the use of hydrogen: It is generally not recommended to introduce hydrogen into tube furnaces unless the hydrogen content is outside the limit explosive concentration and strict safety measures have been taken. If hydrogen gas needs to be used, stainless steel pipes should be used instead of quartz pipes, and both ends of the stainless steel pipes should be water-cooled to prevent the O-ring from being unable to seal due to high temperature.

Ensure airtightness: During the heating process, it is necessary to ensure good airtightness inside the furnace tube to prevent gas leakage from affecting the heating effect or causing safety hazards. Therefore, the sealing condition of flanges and O-rings should be checked regularly, and aging O-rings should be replaced in a timely manner.

3、 Maintain cleanliness

Regular cleaning: Quartz glass tubes are prone to accumulating dust and debris during use, which may cause uneven local heating and generate thermal stress, leading to the rupture of the quartz tube. Therefore, it is necessary to regularly clean the dust and debris on the surface of the quartz tube to maintain its cleanliness.

Correct cleaning method: When cleaning quartz tubes, soak them in fuming nitric acid or hot concentrated sulfuric acid for 3-5 minutes, and repeat several times if necessary. For difficult to clean stains, high-temperature baking or steam blowing methods can be used. However, it should be noted that when the temperature of the tube furnace exceeds 800 ℃, the quartz tube may slowly crystallize and become opaque, and ordinary cleaning methods may not be able to remove these crystals. For this situation, the condition of the quartz tube should be checked regularly. If crystals are found to seriously affect the heating effect, the quartz tube should be replaced in a timely manner.

4、 Reasonable use and placement

Avoid placing materials directly: When burning materials, it is advisable to avoid placing them directly on quartz glass tubes. Instead, containers such as boat shaped crucibles should be used to hold materials to prevent direct contact between the materials and quartz tubes, which can cause damage.

Placing furnace plugs: During the heating process, ceramic or alumina furnace plugs should be placed at both ends of the quartz tube to create a balanced temperature field and prevent O-ring failure or quartz tube rupture caused by excessive temperature at both ends of the furnace tube. The number and position of furnace plugs should be adjusted according to specific circumstances to ensure the best heating effect.

5、 Pay attention to purity and temperature resistance

The temperature resistance of quartz glass tubes is closely related to their purity. The higher the purity of the quartz glass tube, the better its temperature resistance. Therefore, when choosing quartz glass tubes, attention should be paid to their purity indicators and the appropriate temperature resistance level should be selected according to actual usage needs.

The daily maintenance measures for quartz glass tubes in tube furnaces involve temperature control, safe gas use, maintaining cleanliness, reasonable use and placement, as well as paying attention to purity and temperature resistance. By taking these measures, the service life of quartz glass tubes can be effectively extended, ensuring the efficient and stable operation of tube furnaces.

Luverre Quartz is a manufacturer specializing in quartz tubes and other quartz items.We have over 18 years experience with the production of quartz tubes, we will be your reliable partner on quartz tubes and other quartz items.

Luverre Quartz can manufacture customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.