T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2025-11-03 Origin: Site

Quartz glass tube, as a special industrial material made of high-purity silicon dioxide (SiO ₂), plays an irreplaceable role in key fields such as semiconductors, optical communications, aerospace, high-end lighting, and laboratory equipment due to its excellent physical and chemical properties. However, not all quartz glass tubes can meet the needs of these high-end applications.

Core physical and chemical performance standards: quantifiable technical indicators

The standard for high-quality quartz glass tubes is first reflected in a series of strict and measurable physical and chemical properties.

1. Extremely high purity and low impurity content

Standard requirement: The typical feature of high-quality quartz tubes is extremely high purity, with SiO ₂ content typically>99.99% (often expressed as 4N, 4.5N). The key is that certain specific impurity elements must be strictly controlled, such as:

Hydroxyl (OH ⁻) content: Depending on the application, it is divided into low hydroxyl (<5ppm) and high hydroxyl (>150ppm) products. Low hydroxyl tubes are crucial for transmitting ultraviolet light or for optical fiber preforms that are sensitive to water peaks.

Alkali metals (K ⁺, Na ⁺) and heavy metal impurities: These impurities significantly reduce the softening point of materials and cause crystallization (loss of permeability) at high temperatures, damaging the material structure. Its content needs to be in the ppm (parts per million) or even ppb (parts per billion) level.

Verifiability: Purity can be accurately determined by inductively coupled plasma mass spectrometry (ICP-MS), and hydroxyl content can be verified by infrared spectroscopy (FTIR).

2. Excellent optical performance

Standard requirements:

Wide spectral transmission range: High quality quartz glass tubes have extremely high transmittance for a wide spectrum from deep ultraviolet (~185nm) to near-infrared (~2500nm) (e.g. transmittance>85% at 193nm).

UV transmittance is a key indicator: ordinary glass strongly absorbs ultraviolet light, while high-purity quartz glass is an excellent UV transmittance material.

Verifiability: Transmittance can be accurately measured using a UV Vis NIR spectrophotometer, which is direct evidence for determining its optical grade.

3. Excellent thermal performance

Standard requirements:

High softening point: about 1730 ℃, much higher than ordinary glass.

Extremely low coefficient of thermal expansion: about 5.5 × 10 ⁻⁷/℃, which means that under rapid cooling and heating (thermal shock) conditions, its deformation is extremely small and its thermal shock resistance is excellent.

Excellent thermal stability: can be used for a long time at a high temperature of 1100 ℃ without softening or deformation.

Verifiability: The coefficient of thermal expansion can be measured by a thermal mechanical analyzer (TMA), and the softening point can be determined by high-temperature microscopy.

4. Excellent mechanical and electrical performance

Standard requirements:

High hardness and scratch resistance: The Mohs hardness can reach level 7.

Excellent insulation performance: The electrical resistivity can reach over 10 ⊃1;⁶Ω· cm at room temperature, and it can maintain good electrical insulation performance even at high temperatures.

Verifiability: The resistivity can be measured using a high resistance meter.

Product Applications and Advantages: How Standards Transform into Value

The strict physical and chemical standards mentioned above directly determine the performance of quartz glass tubes in high-end applications and the problems they can solve.

1. Application field: Semiconductor manufacturing

Specific applications: Used as diffusion tubes, furnace tubes, boats, carrying silicon wafers for processes such as oxidation, diffusion, annealing, and CVD (chemical vapor deposition) in high-temperature environments.

Problem solved:

High purity standard: prevents impurities such as heavy metals from contaminating silicon wafers during high temperature processes, ensuring the electrical performance and yield of chips.

High thermal stability standard: Ensure that quartz devices do not deform or break during repeated thermal cycles, prolong equipment life, and reduce maintenance costs.

Anti crystallization property: prevents quartz tubes from losing transparency under long-term high temperatures, avoiding crystal point detachment and polluting the process environment.

Product advantages: high yield, low pollution, long lifespan, and high process stability.

2. Application field: Optical communication

Specific applications: As a deposition base tube and a drawing outer tube for optical fiber preforms.

Problem solved:

Low hydroxyl standard: Ensure that optical fibers have extremely low optical attenuation in communication bands (such as 1310nm, 1550nm), reducing signal loss.

High purity and uniformity standards: Ensure precise control of the refractive index distribution of the fiber core and cladding, achieving efficient optical signal transmission.

Product advantages: low loss, high bandwidth, and reliable signal transmission quality.

3. Application areas: high-end lighting and ultraviolet technology

Specific applications: Used for mercury lamps, xenon lamps, and ultraviolet sterilization lamps.

Problem solved:

UV high transmittance standard: enables UV rays to efficiently penetrate the lamp tube for sterilization, curing, or as a light source.

Thermal shock resistance standard: withstand severe temperature changes when the lamp is turned on and off to prevent bursting.

Product advantages: high luminous efficiency, long lifespan, safe and reliable.

Appearance and processing quality: intuitive evaluation criteria

In addition to its intrinsic performance, high-quality quartz glass tubes also have clear standards for appearance and processing.

Bubbles and impurities: There should be no visible bubbles, gas lines, particles or other impurities on the inner and outer walls.

Dimensional accuracy: The tolerances of outer diameter and wall thickness need to be strictly controlled, usually requiring ± 0.1mm or even smaller, to ensure precise installation and use in automated equipment.

Surface smoothness: The surface is smooth and uniform, without scratches, cracks, or cloud like defects.

High quality quartz glass tube is not a simple upgrade of ordinary glass. It is a high-tech product defined by a series of strict standards such as extreme purity, excellent optical and thermal performance, and precise geometric dimensions. These standards are not empty talk, they directly correspond to key issues such as pollution control, signal loss, and equipment lifespan that can be solved in core industrial fields such as semiconductors, optical communications, and lighting, and ultimately translate into significant product advantages that improve yield, ensure performance, and reduce costs.

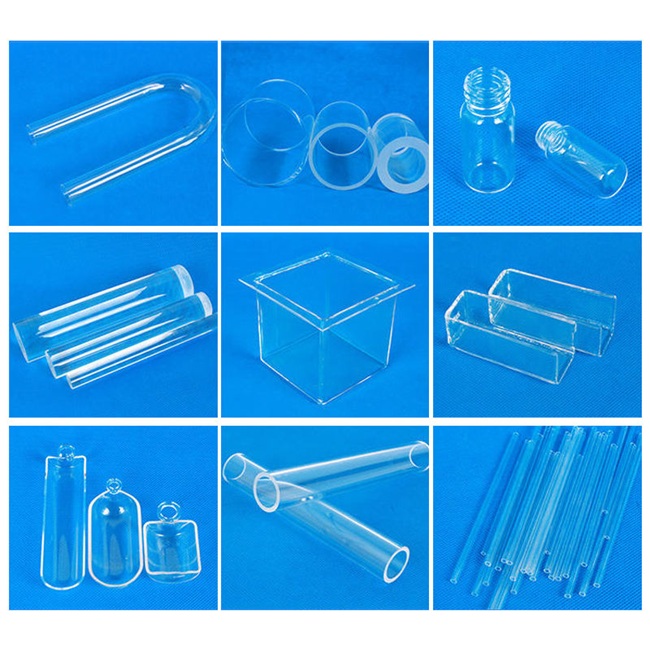

Luverre Quartz can manufacture customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.