T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

Q: As an optical instrument manufacturer or R&D personnel, do you face the following challenges?

Do you need materials with high transmittance and low thermal expansion to ensure the accuracy of optical systems?

Worried about the performance degradation of optical components caused by UV or high temperature environments?

Looking for corrosion-resistant and highly stable window or substrate?

Do you need customized sizes and shapes to accommodate special instrument designs?

Answer: Customizing quartz plates is your ideal solution. It can provide over 99% high transmittance (from ultraviolet to infrared bands), almost zero thermal expansion coefficient, and excellent chemical stability, directly solving the core requirements of optical instruments for material accuracy, environmental resistance, and long-term reliability.

In the design and manufacturing of modern optical instruments, the selection of core optical components directly determines the performance, accuracy, and reliability of the instrument. Quartz plate (quartz glass plate), as a high-performance optical material, has become one of the preferred choices for high-end optical instruments.

Key applications of quartz plates in optical instruments

Quartz plate is an optical material mainly composed of high-purity silicon dioxide (SiO ₂), which is made through precision melting and processing. In optical instruments, it is widely used in the following scenarios:

-Optical window and protective film: used as observation windows for spectrometers, microscopes, laser equipment, and other instruments to protect internal components from environmental erosion.

-Lens and Prism Substrate: Used as a substrate for lenses, prisms, and reflectors in ultraviolet, visible, and infrared optical systems.

-Precision optical platform: an optical platform used for high-precision instruments such as interferometers and lithography machines to ensure stable optical path transmission.

-Sensor packaging: Provides transparent and durable packaging protection for optical sensors in high temperature or corrosive environments.

Advantages of Quartz Plates: Why is it an ideal choice for optical instruments?

High transparency and wide spectral range

Quartz plates have excellent transparency in the ultraviolet (UV), visible light to near-infrared (IR) bands (usually UV grade quartz has a transmittance of over 90%). This makes it suitable for full spectrum optical systems, especially irreplaceable in ultraviolet laser equipment and astronomical observation instruments.

Excellent thermal stability and low thermal expansion coefficient

The thermal expansion coefficient of quartz is extremely low (about 5.5 × 10 ⁻⁷/℃), and it can maintain stable shape and optical properties at high or sudden temperature changes. For example, in high-temperature microscopes or aerospace optical equipment, quartz plates can avoid aberrations caused by thermal deformation.

Excellent chemical durability and mechanical strength

Quartz plate is acid and alkali resistant, corrosion-resistant, and not easily aged in humid or chemically exposed environments. Its hardness is high (Mohs 7), and the surface can be polished to achieve optical grade flatness (roughness<1nm), making it suitable for precision optical coating.

High laser damage threshold

For high-power laser systems such as laser cutting machines and optical radars, quartz plates can withstand high energy densities to avoid performance degradation caused by laser burns.

The core problem solved by quartz plate

-Poor environmental adaptability: Ordinary optical glass has a high absorption rate in the ultraviolet band and is susceptible to chemical corrosion. Quartz plates make up for this deficiency and expand the application range of instruments in special environments.

-Thermal deformation leads to decreased accuracy: In laboratory or industrial scenarios with large temperature fluctuations, the low thermal expansion characteristics of quartz plates ensure the long-term stability of optical systems.

-Short service life: the abrasion resistance and anti-aging characteristics of quartz plate extend the maintenance cycle of optical instruments and reduce the operating cost.

Why choose us as the supplier of quartz plates?

Professional customization capability

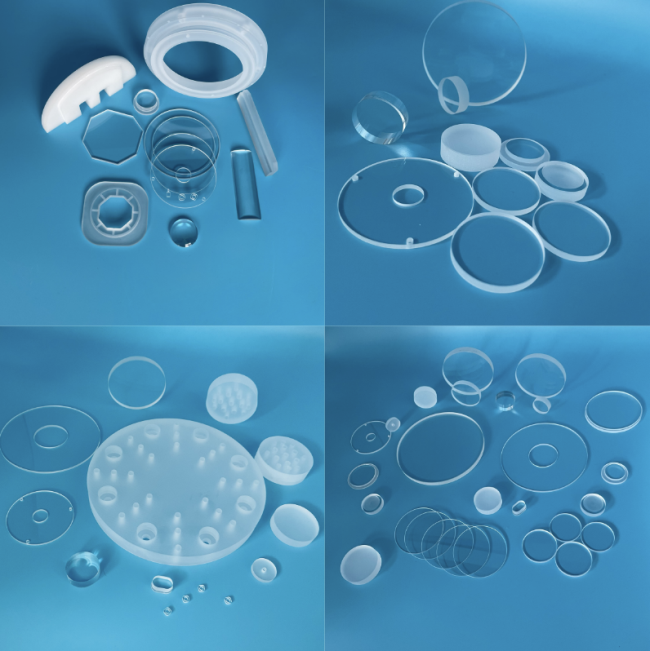

We have over 19 years of experience in producing quartz products and can provide customized services according to customer needs

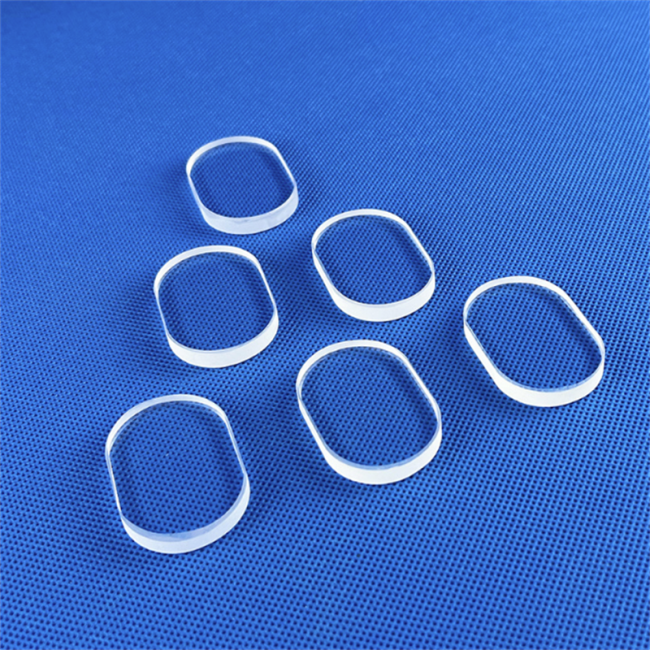

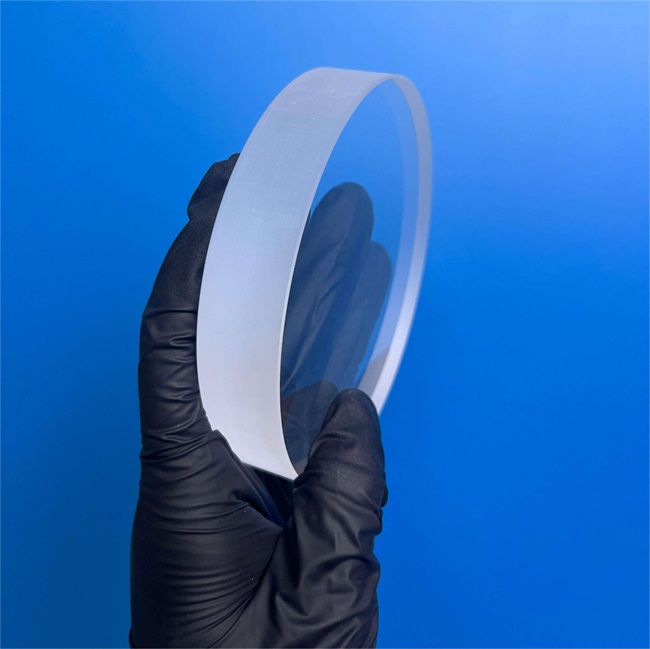

-Flexible customization of size and shape: supports circular, rectangular, and irregular cutting, with a thickness of 0.1mm to 50mm, and a maximum size of up to 500mm × 600mm.

-Surface accuracy control: Provides optical grade polishing, coating (anti reflective film, reflective film, etc.), drilling, chamfering and other processing.

-There are various material grades, including UV grade (JGS1), infrared grade (JGS3), low hydroxyl quartz, etc., to meet the needs of different frequency bands.

Strict quality control system

From raw material screening (purity above 99.99%) to finished product testing, we follow the ISO 9001 quality management standard to ensure that every quartz plate:

-Optical uniformity (<5 × 10 ⁻⁶)

-No bubbles, no impurities (Class 0)

-Surface accuracy reaches λ/10

Global Services and Rapid Response

As a professional manufacturer, we provide multilingual technical support, logistics optimization solutions, and after-sales tracking services to global customers to ensure timely and reliable delivery.

Customer application cases (anonymous)

-Case 1: German optical instrument manufacturer

The customer needs to customize a high transmittance UV quartz window (size 150mm × 200mm, thickness 2mm) for the UV spectrophotometer. The JGS1 grade quartz plate we provide has a transmittance of ≥ 92% at a wavelength of 250nm, which solves the signal attenuation problem caused by ordinary glass UV absorption for customers and improves instrument accuracy by 30%.

-Case 2: American space research institutions

The optical platform used by the customer for satellite remote sensing systems needs to operate in an environment of -80 ℃ to 120 ℃. The low expansion quartz plate we provide (thermal expansion coefficient<5 × 10 ⁻⁷/℃) ensures the dimensional stability of the platform under extreme temperatures, and the project has been running stably for 3 years.

-Case 3: Japanese Laser Equipment Company

The customer's high-power laser cutting machine requires protective lenses that are resistant to high temperatures and have a high laser damage threshold. The damage threshold of the quartz plate coated with anti reflective film we provide is 15J/cm ⊃2; (@ 1064nm), and the service life is extended to 5 times that of ordinary glass.

Quartz plates have become an indispensable component of high-end optical instruments due to their unique optical, thermal, and chemical properties. Choosing a professional and reliable supplier can not only improve instrument performance, but also reduce long-term maintenance costs.

We are committed to providing customized quartz plate solutions for global customers. If you have any needs for upgrading or customizing optical instruments, please feel free to contact us for free samples and technical support - let us use professional craftsmanship to help your optical system be more accurate and durable!

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.