T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

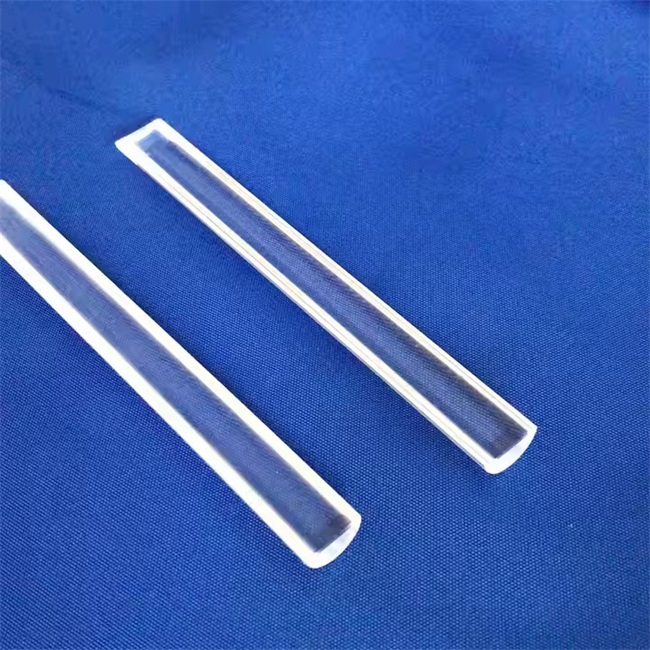

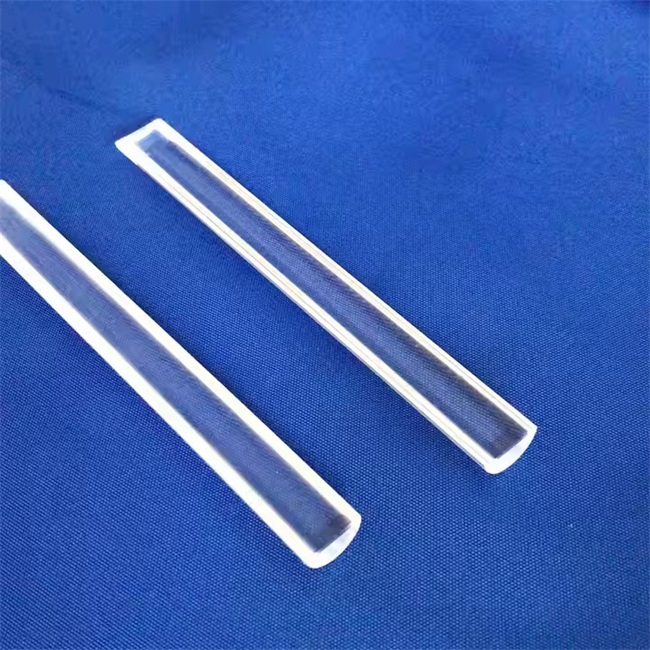

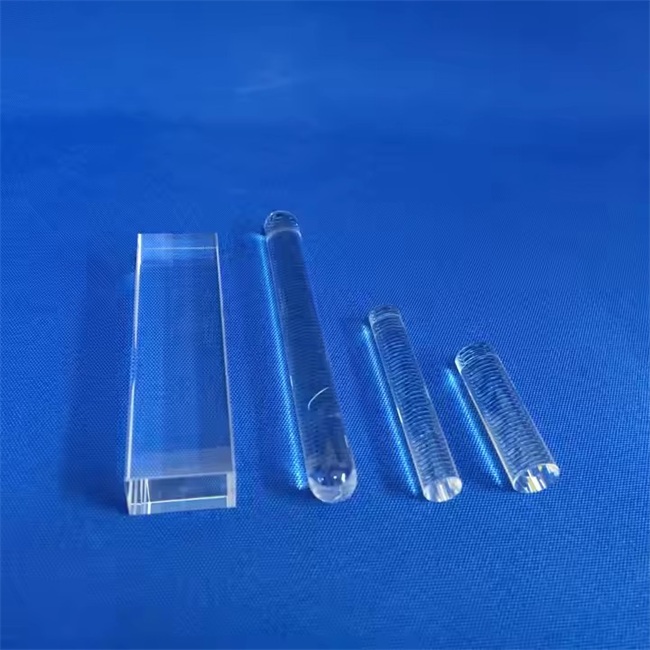

10-100mm diameter transparent quartz glass rod

Transparent quartz glass rod with a diameter of 10-100mm is a high-performance special glass material with extremely high purity, excellent optical properties, and outstanding physical and chemical properties.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

Transparent quartz glass rod with a diameter of 10-100mm is a high-performance special glass material with extremely high purity, excellent optical properties, and outstanding physical and chemical properties. It is mainly composed of silicon dioxide (SiO ₂), with a purity of over 99.99%. This type of quartz glass rod is widely used in various high-tech fields such as semiconductors, fiber optic communication, optical instruments, chemical engineering, aerospace, etc. As a professional quartz product manufacturer with years of experience in foreign trade, we are well aware of the stringent requirements of various industries for the performance of core materials.

Product Core Advantage: Why Our Quartz Glass Rod Stands Out

Our transparent quartz glass rod is made of high-purity fused silica sand by advanced electric melting or gas refining process, which ensures the stability and reliability of the product in extreme environments. Its main advantages include:

Extremely high thermal stability: with a softening point of up to 1730 ℃, it can work for a long time at 1100 ℃, with an extremely low coefficient of thermal expansion, and can withstand drastic temperature changes without bursting.

Excellent optical performance: It has high transmittance in a wide spectral range from ultraviolet to infrared (especially in the ultraviolet band, transmittance far exceeds that of ordinary glass), making it an ideal choice for optical applications.

Excellent chemical inertness: except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acidic substances, has strong resistance to metal and solution corrosion, and has a long service life.

Superior mechanical strength: good surface condition, high Young's modulus, pressure resistance, bending resistance, and excellent mechanical properties.

Extremely low impurity content: Silicon dioxide (SiO2) content ≥ 99.99%, ensuring no pollution is introduced when applied in high-end fields such as semiconductors and photovoltaics.

Widely applicable fields: from laboratories to industrial production lines

With the above advantages, our quartz glass rods serve numerous high-tech and traditional industrial fields worldwide:

Semiconductor and Photovoltaic Industry: Used as wafer carriers, diffusion furnace tubes, supports and blades in CVD processes, its high purity and high temperature resistance ensure the production quality of chips and solar cells.

Optoelectronics and Lighting Industry: As the lamp tube and outer shell of halogen lamps, xenon lamps, UV lamps and other electric light sources, their excellent transparency and heat resistance ensure the efficiency and lifespan of the light source.

Laboratory and research equipment: used for manufacturing test tubes, crucibles, observation windows, optical prisms, and various customized experimental instruments to meet the requirements of scientific research for material accuracy and stability.

Industrial heating and heat treatment: As the furnace, insulation screen, and support components of sintering furnaces and vacuum furnaces, it maintains structural integrity in high temperature environments.

Chemical industry: used for making observation windows, sensor protection tubes, and transport pipelines in corrosive environments.

What key issues can we solve?

Choosing our quartz glass rod means you can effectively tackle the following challenges:

1. Solve the problem of material deformation and failure in high temperature environments: replace ordinary glass or metal, and ensure production continuity without deformation or crystallization under long-term high temperature.

2. Avoid contamination risks in high-purity processes: The extremely high purity ensures that it will not become a source of contamination in applications sensitive to impurities such as semiconductors, photovoltaics, and optical fibers.

3. Improve the efficiency and accuracy of optical systems: Excellent UV transmittance ensures the performance of UV curing, spectral analysis, and other equipment.

4. Reduce downtime and maintenance costs caused by equipment component failures: Excellent durability and thermal shock resistance reduce unplanned downtime and improve overall production efficiency.

Why choose us? Your global quartz solution partner

Deep production expertise: We have been focusing on the field of quartz products for many years and have a complete set of process technologies from raw material purification to precision processing.

Flexible customization services: We provide comprehensive customization support, including:

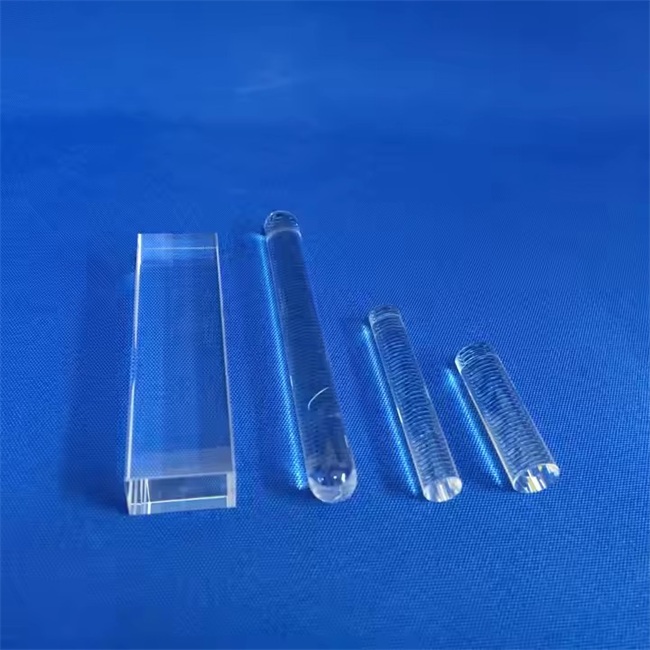

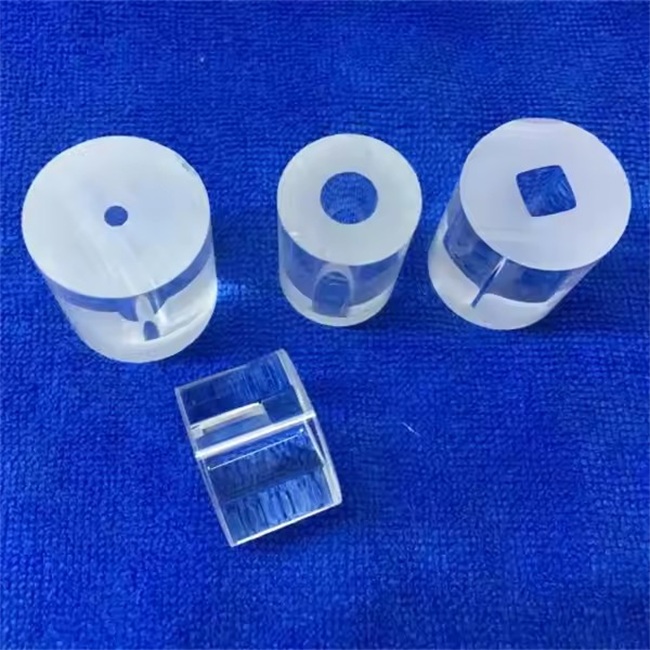

Size customization: In addition to standard diameters (10-100mm), non-standard diameters, lengths, and tolerances can be customized.

Shape and Processing: Supports secondary precision processing such as cutting, edging, chamfering, drilling, and flame polishing.

Surface treatment: Different surface states such as matte and frosted can be provided according to requirements.

Strict quality control: Each quartz rod undergoes strict size, bubble, impurity, and transmittance testing before leaving the factory to ensure compliance with international standards.

Global foreign trade experience: We are familiar with international trade processes and can provide smooth communication, efficient logistics, and competitive prices for global customers.

Customer real case sharing

Case 1 (a well-known lighting manufacturer in Europe): The customer's quartz rod, which was originally used to manufacture high-power halogen lamps, often experienced premature loss of transparency due to insufficient thermal stability of the bulb. After switching to the 25mm diameter high-purity quartz rod we provided, the product life was increased by more than 30%, and customer satisfaction significantly improved.

Case 2 (a semiconductor equipment supplier in Southeast Asia): The customer requires a quartz furnace tube support rod with a diameter of 80mm and a length exceeding 2 meters, which has extremely strict requirements for straightness and purity. We have successfully delivered products that fully meet their drawing requirements by optimizing the process, helping customers solve supply chain challenges for core components.

Are you ready to search for reliable quartz materials for your project?

Whether you need standard sized inventory products or customized solutions with special requirements, we are ready. Please contact us immediately to obtain samples or inquire about your specific needs. Our professional team will provide you with the most suitable solution.

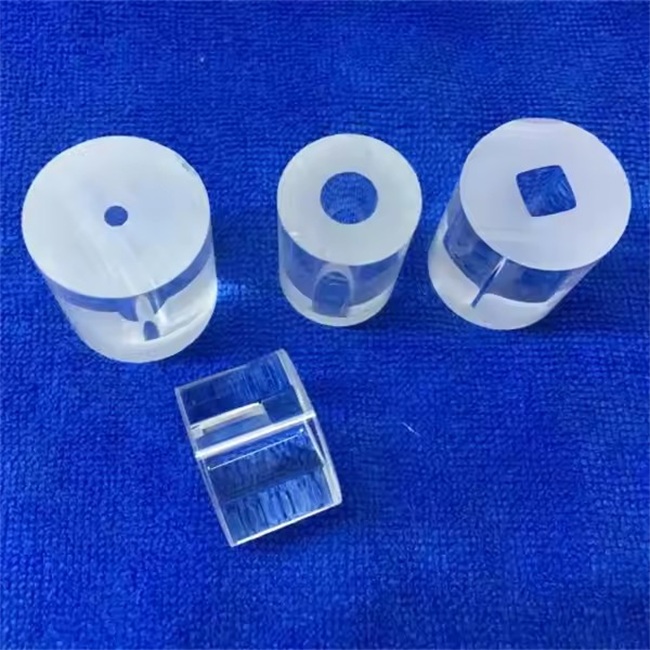

Luverre Quartz can manufacture customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.

Transparent quartz glass rod with a diameter of 10-100mm is a high-performance special glass material with extremely high purity, excellent optical properties, and outstanding physical and chemical properties. It is mainly composed of silicon dioxide (SiO ₂), with a purity of over 99.99%. This type of quartz glass rod is widely used in various high-tech fields such as semiconductors, fiber optic communication, optical instruments, chemical engineering, aerospace, etc. As a professional quartz product manufacturer with years of experience in foreign trade, we are well aware of the stringent requirements of various industries for the performance of core materials.

Product Core Advantage: Why Our Quartz Glass Rod Stands Out

Our transparent quartz glass rod is made of high-purity fused silica sand by advanced electric melting or gas refining process, which ensures the stability and reliability of the product in extreme environments. Its main advantages include:

Extremely high thermal stability: with a softening point of up to 1730 ℃, it can work for a long time at 1100 ℃, with an extremely low coefficient of thermal expansion, and can withstand drastic temperature changes without bursting.

Excellent optical performance: It has high transmittance in a wide spectral range from ultraviolet to infrared (especially in the ultraviolet band, transmittance far exceeds that of ordinary glass), making it an ideal choice for optical applications.

Excellent chemical inertness: except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acidic substances, has strong resistance to metal and solution corrosion, and has a long service life.

Superior mechanical strength: good surface condition, high Young's modulus, pressure resistance, bending resistance, and excellent mechanical properties.

Extremely low impurity content: Silicon dioxide (SiO2) content ≥ 99.99%, ensuring no pollution is introduced when applied in high-end fields such as semiconductors and photovoltaics.

Widely applicable fields: from laboratories to industrial production lines

With the above advantages, our quartz glass rods serve numerous high-tech and traditional industrial fields worldwide:

Semiconductor and Photovoltaic Industry: Used as wafer carriers, diffusion furnace tubes, supports and blades in CVD processes, its high purity and high temperature resistance ensure the production quality of chips and solar cells.

Optoelectronics and Lighting Industry: As the lamp tube and outer shell of halogen lamps, xenon lamps, UV lamps and other electric light sources, their excellent transparency and heat resistance ensure the efficiency and lifespan of the light source.

Laboratory and research equipment: used for manufacturing test tubes, crucibles, observation windows, optical prisms, and various customized experimental instruments to meet the requirements of scientific research for material accuracy and stability.

Industrial heating and heat treatment: As the furnace, insulation screen, and support components of sintering furnaces and vacuum furnaces, it maintains structural integrity in high temperature environments.

Chemical industry: used for making observation windows, sensor protection tubes, and transport pipelines in corrosive environments.

What key issues can we solve?

Choosing our quartz glass rod means you can effectively tackle the following challenges:

1. Solve the problem of material deformation and failure in high temperature environments: replace ordinary glass or metal, and ensure production continuity without deformation or crystallization under long-term high temperature.

2. Avoid contamination risks in high-purity processes: The extremely high purity ensures that it will not become a source of contamination in applications sensitive to impurities such as semiconductors, photovoltaics, and optical fibers.

3. Improve the efficiency and accuracy of optical systems: Excellent UV transmittance ensures the performance of UV curing, spectral analysis, and other equipment.

4. Reduce downtime and maintenance costs caused by equipment component failures: Excellent durability and thermal shock resistance reduce unplanned downtime and improve overall production efficiency.

Why choose us? Your global quartz solution partner

Deep production expertise: We have been focusing on the field of quartz products for many years and have a complete set of process technologies from raw material purification to precision processing.

Flexible customization services: We provide comprehensive customization support, including:

Size customization: In addition to standard diameters (10-100mm), non-standard diameters, lengths, and tolerances can be customized.

Shape and Processing: Supports secondary precision processing such as cutting, edging, chamfering, drilling, and flame polishing.

Surface treatment: Different surface states such as matte and frosted can be provided according to requirements.

Strict quality control: Each quartz rod undergoes strict size, bubble, impurity, and transmittance testing before leaving the factory to ensure compliance with international standards.

Global foreign trade experience: We are familiar with international trade processes and can provide smooth communication, efficient logistics, and competitive prices for global customers.

Customer real case sharing

Case 1 (a well-known lighting manufacturer in Europe): The customer's quartz rod, which was originally used to manufacture high-power halogen lamps, often experienced premature loss of transparency due to insufficient thermal stability of the bulb. After switching to the 25mm diameter high-purity quartz rod we provided, the product life was increased by more than 30%, and customer satisfaction significantly improved.

Case 2 (a semiconductor equipment supplier in Southeast Asia): The customer requires a quartz furnace tube support rod with a diameter of 80mm and a length exceeding 2 meters, which has extremely strict requirements for straightness and purity. We have successfully delivered products that fully meet their drawing requirements by optimizing the process, helping customers solve supply chain challenges for core components.

Are you ready to search for reliable quartz materials for your project?

Whether you need standard sized inventory products or customized solutions with special requirements, we are ready. Please contact us immediately to obtain samples or inquire about your specific needs. Our professional team will provide you with the most suitable solution.

Luverre Quartz can manufacture customized quartz tubes in various shapes, such as spiral, square, round, with processing including cutting, bending, welding, etc., and available in different colors, such as transparent quartz tubes, opaque quartz tubes, milky white quartz tubes, red quartz tubes, and so on.