T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

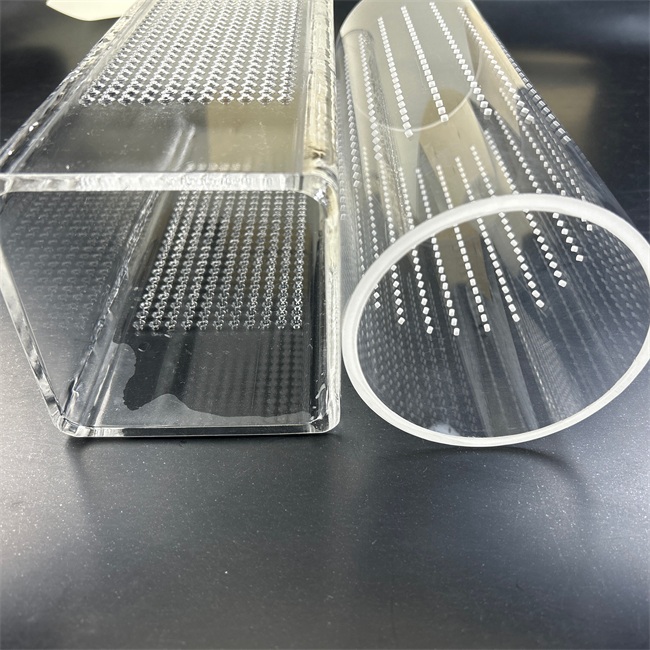

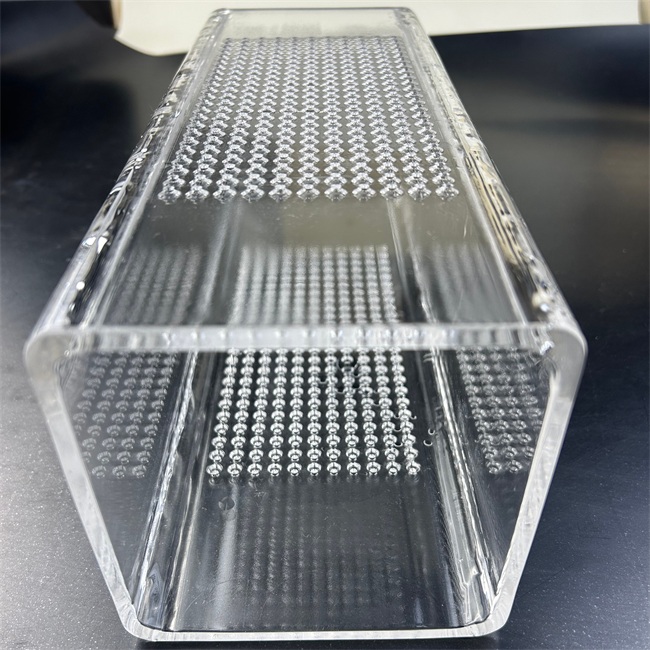

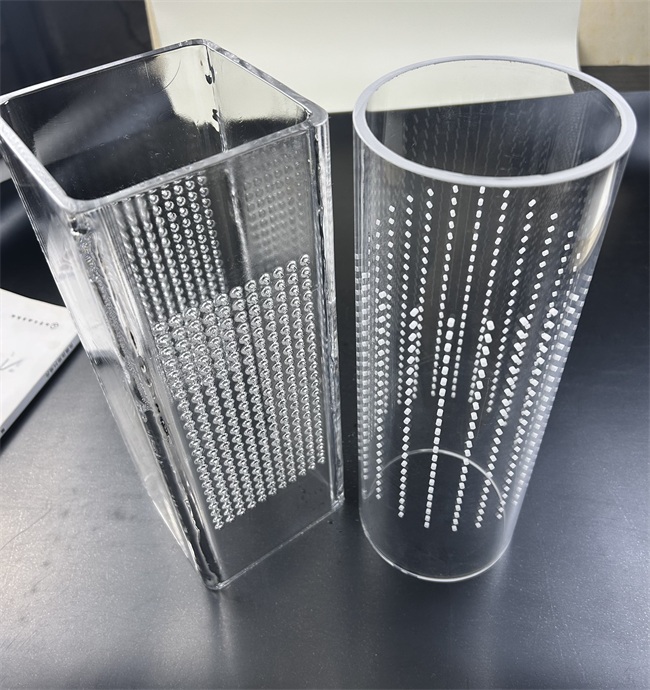

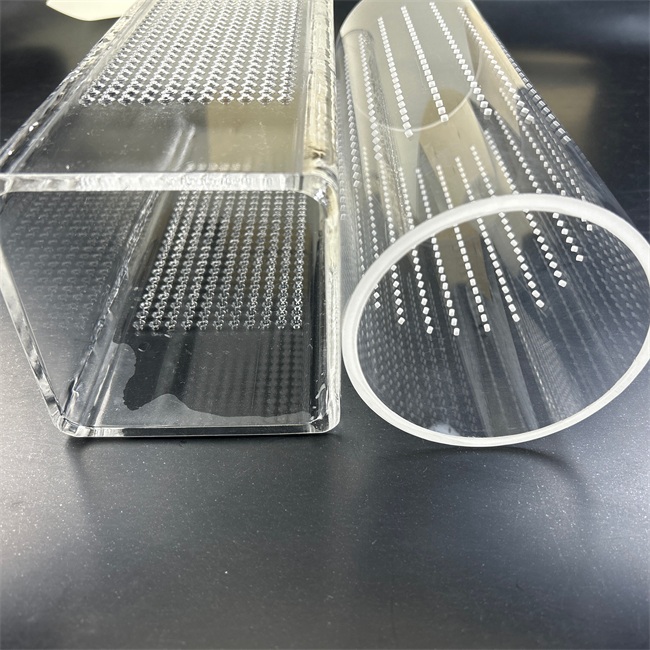

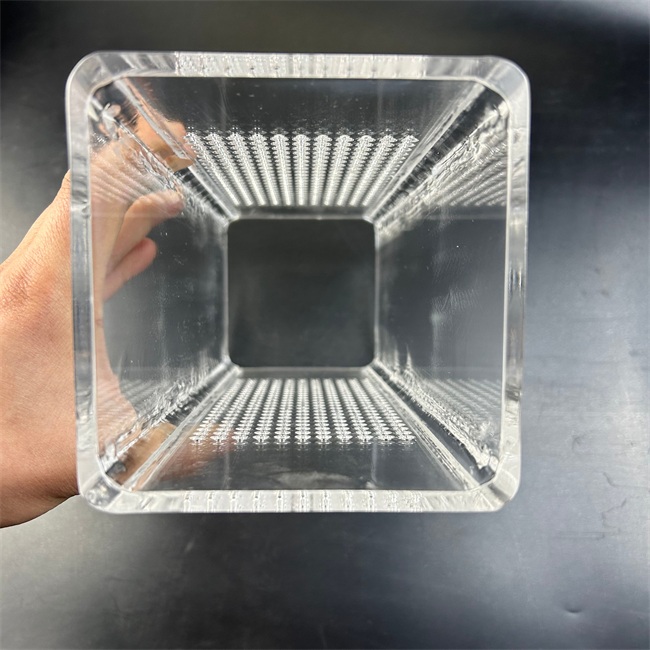

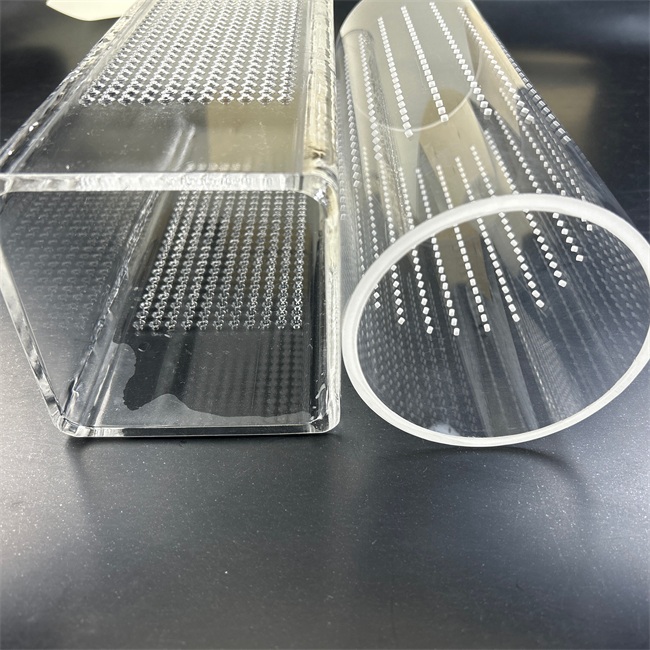

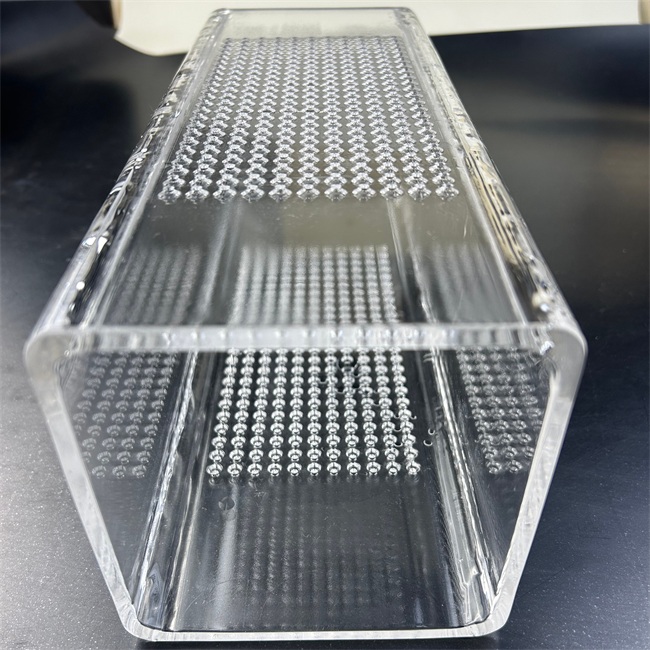

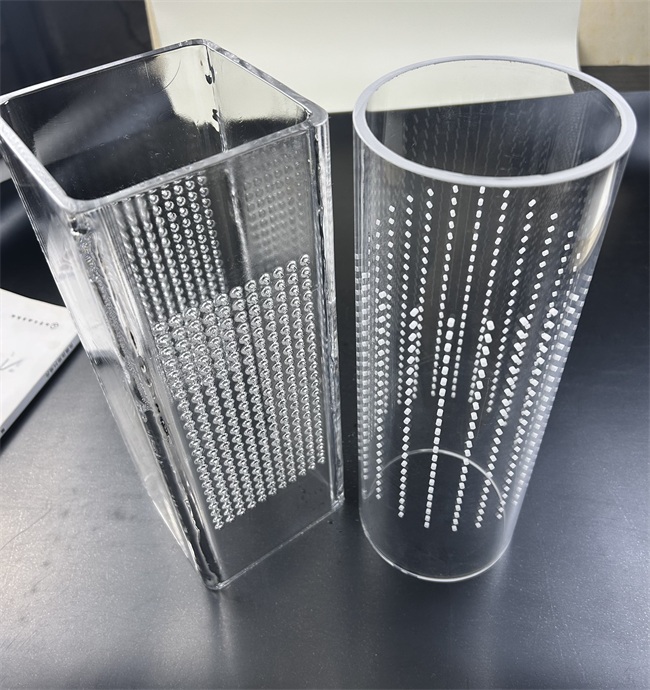

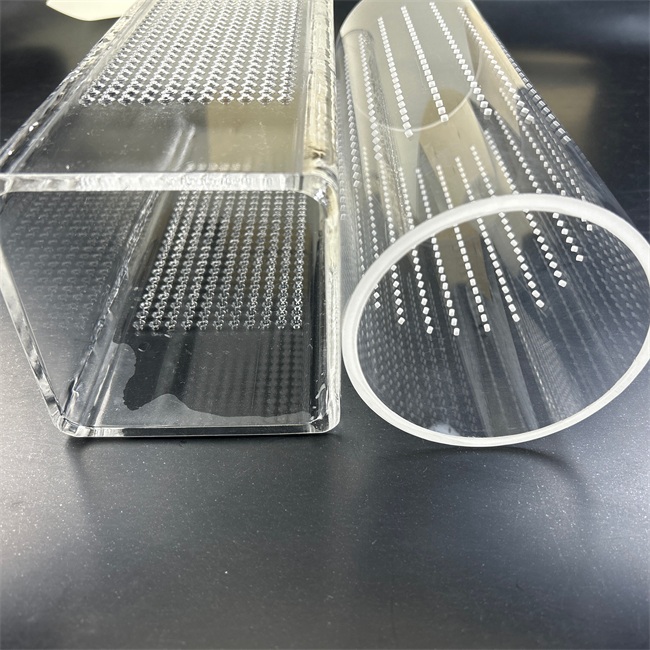

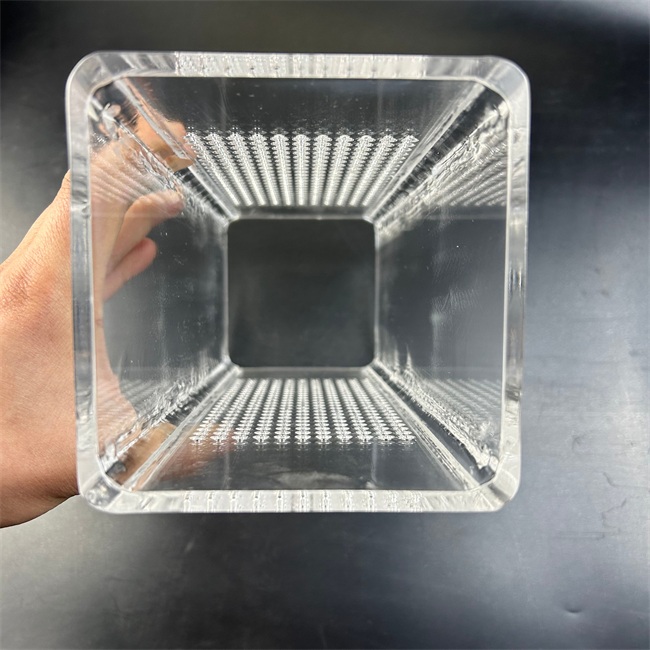

Square circular quartz glass tube

These two fundamental but crucial forms each have unique advantages and serve different application scenarios.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

As a foreign trade enterprise specializing in the research and production of quartz products, we are well aware of the core position of square and circular quartz glass tubes in modern industry and technology. These two fundamental but crucial forms each have unique advantages and serve different application scenarios.

Product Advantage: Why does our quartz glass tube stand out?

Our square and circular quartz glass tubes are made of high-purity natural quartz sand and manufactured through advanced electric melting or gas refining processes, ensuring that the products have unparalleled inherent advantages:

Extremely high thermal stability: with a softening point of up to 1730 ℃, it can work for a long time at 1100 ℃, and has higher instantaneous temperature resistance, able to withstand drastic temperature changes without bursting.

Excellent optical performance: It has extremely high transmittance in the full spectrum from ultraviolet to infrared (especially in the ultraviolet region, with a transmittance of over 80%), making it an ideal choice for optical applications.

Excellent corrosion resistance: except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acidic substances, and its acid resistance is 30 times that of ceramics and 150 times that of stainless steel.

Extremely low coefficient of thermal expansion: The coefficient of thermal expansion is extremely small, only 5.5 × 10 ^ (-7)/℃, which means that its shape and size remain stable under rapid cooling and heating conditions.

Excellent electrical insulation: Its resistance value is equivalent to ten thousand times that of ordinary glass, making it an excellent electrical insulation material.

Special advantages in form:

Circular quartz tube: standard shape, uniform mechanical strength, easy to seal and connect, is the preferred choice for fluid transmission, tube furnaces, and conventional heating containers.

Square quartz tube: provides a larger surface area, which can maintain the optimal distance between the wafer and the tube wall in semiconductor diffusion processes; Compact structure, convenient for modular integration in limited space, reduces light scattering, and performs better in certain optical systems.

Application areas: Your industry challenges, our solutions

Our quartz glass tube is not only a material, but also a key component for solving industry-specific problems.

Semiconductor and Photovoltaic Industry:

Problem solving: Metal contamination during high-temperature processes, deformation caused by thermal stress, and inadequate cleanliness.

Application: Square tubes are widely used in LPCVD (low-pressure chemical vapor deposition) furnace tubes and diffusion furnaces as carriers for chips; Circular tubes are used for quartz boat supports, load-bearing rods, and gas delivery pipelines.

Optoelectronics and Lighting Industry:

Solution: Traditional glass has low UV transmittance and is prone to blackening and aging at high temperatures.

Application: Circular quartz tube is the core material for the shell of halogen lamps, mercury lamps, and UV sterilization lamps; Square tubes are used for UV curing equipment and optical detection windows with special structures.

Chemical and laboratory equipment:

Problem solving: Corrosion of containers by highly corrosive media, safety under high temperature and high pressure.

Application: As the observation window, condenser tube, and core component of precision experimental instruments for reaction vessels, it provides a high-purity, corrosion-resistant and safe operating environment.

Environmental protection and analytical instruments:

Problem solved: High temperature and corrosive flue gas damage the sampling tube, affecting measurement accuracy.

Application: Used for sampling tubes and heat tracing tubes in CEMS (Continuous Emission Monitoring System), ensuring no loss or reaction of gas samples during transmission.

Customized service: Your needs, our blueprint

We firmly believe that no two customers have exactly the same needs. Therefore, we provide in-depth customized services:

Size customization: Diameter, side length, wall thickness, and length can be produced according to demand, whether it is micro experimental tubes or large industrial furnace tubes.

Customization of Shape and Structure: In addition to standard square and circular shapes, special structures such as D-shaped, oval shaped, flanged, perforated, sealed, etc. can be customized.

Purity and performance customization: Based on your process requirements, we provide products with different purity levels (such as low hydroxyl, high-purity seamless pipes).

Surface treatment: Grinding, sandblasting, polishing and other treatments can be carried out to meet specific optical or sealing requirements.

Why choose us? ——The common choice of global customers

1. Source manufacturer, cost advantage: We are a manufacturer with a complete industrial chain, no intermediate links, and provide you with the most competitive prices.

2. Foreign trade expert, serving the world: With rich export experience, proficient in international trade processes, able to efficiently handle various orders, and provide professional multilingual technical support.

3. Strict quality control, trusted choice: From raw materials to finished products, every process undergoes strict testing (including size, bubbles, impurities, transmittance, etc.) to ensure that every quartz tube meets high standards.

4. Technical team, strong support: With an experienced team of engineers, we can provide selection suggestions and solutions for your application, serving as your reliable technical support.

Real customer cases

Case 1 (a well-known semiconductor equipment manufacturer in Europe):

Requirement: We need a batch of oversized, low hydroxyl content square quartz furnace tubes for our new generation 12 inch wafer diffusion process, with ultra smooth inner walls and no micro defects.

Challenge: The size exceeds the norm, with extremely high requirements for verticality and flatness at high temperatures.

Solution: Our technical team optimized the melting and cooling processes, using special molds and precision annealing technology, and successfully delivered products that fully meet specifications, helping customers increase equipment yield by nearly 2 percentage points.

Case 2 (a North American environmental monitoring company):

Requirement: Customized composite circular quartz sampling tube with multi-channel structure, requiring high temperature resistance and inert coating on the inner wall.

Solution: We accurately controlled the size and concentricity of multiple inner holes based on their drawings, and successfully applied special inert coating technology to solve the adsorption problem of sample gases during transportation, which has been highly recognized by customers.

Are you ready to find the most suitable quartz glass tube solution for your project?

Feel free to contact us anytime for free samples, technical consultation, or instant quotes. Let us empower your products with professional quartz glass technology!

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.

As a foreign trade enterprise specializing in the research and production of quartz products, we are well aware of the core position of square and circular quartz glass tubes in modern industry and technology. These two fundamental but crucial forms each have unique advantages and serve different application scenarios.

Product Advantage: Why does our quartz glass tube stand out?

Our square and circular quartz glass tubes are made of high-purity natural quartz sand and manufactured through advanced electric melting or gas refining processes, ensuring that the products have unparalleled inherent advantages:

Extremely high thermal stability: with a softening point of up to 1730 ℃, it can work for a long time at 1100 ℃, and has higher instantaneous temperature resistance, able to withstand drastic temperature changes without bursting.

Excellent optical performance: It has extremely high transmittance in the full spectrum from ultraviolet to infrared (especially in the ultraviolet region, with a transmittance of over 80%), making it an ideal choice for optical applications.

Excellent corrosion resistance: except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acidic substances, and its acid resistance is 30 times that of ceramics and 150 times that of stainless steel.

Extremely low coefficient of thermal expansion: The coefficient of thermal expansion is extremely small, only 5.5 × 10 ^ (-7)/℃, which means that its shape and size remain stable under rapid cooling and heating conditions.

Excellent electrical insulation: Its resistance value is equivalent to ten thousand times that of ordinary glass, making it an excellent electrical insulation material.

Special advantages in form:

Circular quartz tube: standard shape, uniform mechanical strength, easy to seal and connect, is the preferred choice for fluid transmission, tube furnaces, and conventional heating containers.

Square quartz tube: provides a larger surface area, which can maintain the optimal distance between the wafer and the tube wall in semiconductor diffusion processes; Compact structure, convenient for modular integration in limited space, reduces light scattering, and performs better in certain optical systems.

Application areas: Your industry challenges, our solutions

Our quartz glass tube is not only a material, but also a key component for solving industry-specific problems.

Semiconductor and Photovoltaic Industry:

Problem solving: Metal contamination during high-temperature processes, deformation caused by thermal stress, and inadequate cleanliness.

Application: Square tubes are widely used in LPCVD (low-pressure chemical vapor deposition) furnace tubes and diffusion furnaces as carriers for chips; Circular tubes are used for quartz boat supports, load-bearing rods, and gas delivery pipelines.

Optoelectronics and Lighting Industry:

Solution: Traditional glass has low UV transmittance and is prone to blackening and aging at high temperatures.

Application: Circular quartz tube is the core material for the shell of halogen lamps, mercury lamps, and UV sterilization lamps; Square tubes are used for UV curing equipment and optical detection windows with special structures.

Chemical and laboratory equipment:

Problem solving: Corrosion of containers by highly corrosive media, safety under high temperature and high pressure.

Application: As the observation window, condenser tube, and core component of precision experimental instruments for reaction vessels, it provides a high-purity, corrosion-resistant and safe operating environment.

Environmental protection and analytical instruments:

Problem solved: High temperature and corrosive flue gas damage the sampling tube, affecting measurement accuracy.

Application: Used for sampling tubes and heat tracing tubes in CEMS (Continuous Emission Monitoring System), ensuring no loss or reaction of gas samples during transmission.

Customized service: Your needs, our blueprint

We firmly believe that no two customers have exactly the same needs. Therefore, we provide in-depth customized services:

Size customization: Diameter, side length, wall thickness, and length can be produced according to demand, whether it is micro experimental tubes or large industrial furnace tubes.

Customization of Shape and Structure: In addition to standard square and circular shapes, special structures such as D-shaped, oval shaped, flanged, perforated, sealed, etc. can be customized.

Purity and performance customization: Based on your process requirements, we provide products with different purity levels (such as low hydroxyl, high-purity seamless pipes).

Surface treatment: Grinding, sandblasting, polishing and other treatments can be carried out to meet specific optical or sealing requirements.

Why choose us? ——The common choice of global customers

1. Source manufacturer, cost advantage: We are a manufacturer with a complete industrial chain, no intermediate links, and provide you with the most competitive prices.

2. Foreign trade expert, serving the world: With rich export experience, proficient in international trade processes, able to efficiently handle various orders, and provide professional multilingual technical support.

3. Strict quality control, trusted choice: From raw materials to finished products, every process undergoes strict testing (including size, bubbles, impurities, transmittance, etc.) to ensure that every quartz tube meets high standards.

4. Technical team, strong support: With an experienced team of engineers, we can provide selection suggestions and solutions for your application, serving as your reliable technical support.

Real customer cases

Case 1 (a well-known semiconductor equipment manufacturer in Europe):

Requirement: We need a batch of oversized, low hydroxyl content square quartz furnace tubes for our new generation 12 inch wafer diffusion process, with ultra smooth inner walls and no micro defects.

Challenge: The size exceeds the norm, with extremely high requirements for verticality and flatness at high temperatures.

Solution: Our technical team optimized the melting and cooling processes, using special molds and precision annealing technology, and successfully delivered products that fully meet specifications, helping customers increase equipment yield by nearly 2 percentage points.

Case 2 (a North American environmental monitoring company):

Requirement: Customized composite circular quartz sampling tube with multi-channel structure, requiring high temperature resistance and inert coating on the inner wall.

Solution: We accurately controlled the size and concentricity of multiple inner holes based on their drawings, and successfully applied special inert coating technology to solve the adsorption problem of sample gases during transportation, which has been highly recognized by customers.

Are you ready to find the most suitable quartz glass tube solution for your project?

Feel free to contact us anytime for free samples, technical consultation, or instant quotes. Let us empower your products with professional quartz glass technology!

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.