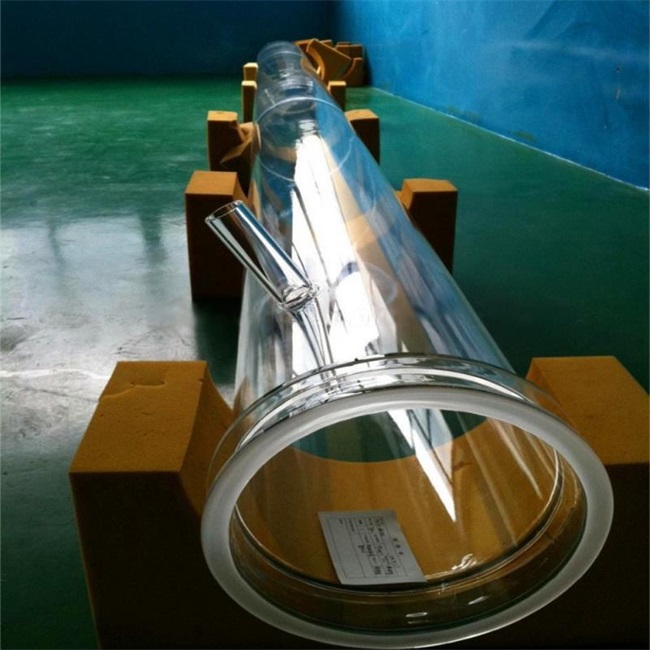

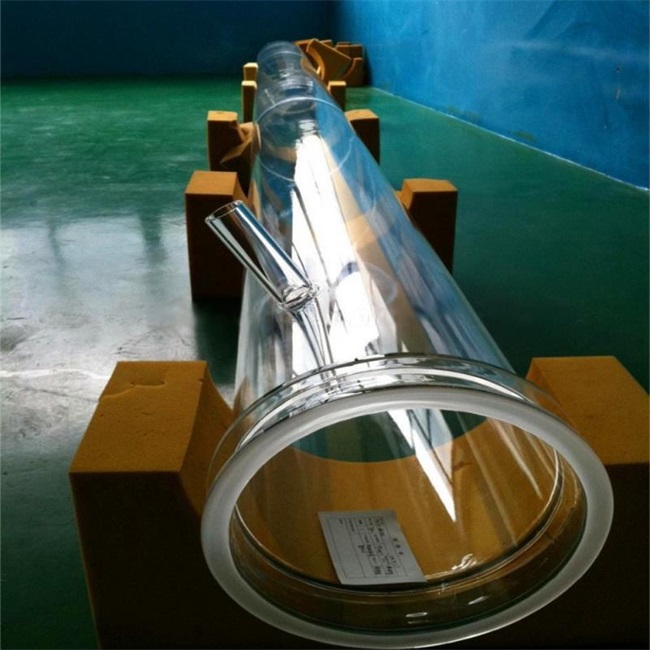

Laboratory high temperature process furnace quartz tube

Quartz tube is a key component of high-temperature experimental equipment made of high-purity silica

Main features:

- High temperature resistance: Can withstand temperatures up to 1200 ° C or even higher, maintaining good structural integrity in high-temperature environments.

Chemical resistance: It is highly resistant to most acids, alkalis, and corrosive chemicals, preventing sample contamination.

Thermal stability: Low thermal expansion coefficient minimizes deformation under rapid temperature changes, making it less prone to thermal cracking.

Optical properties: transparent to ultraviolet and infrared rays, suitable for photochemical and optical experiments.

Application

Quartz tubes are widely used in laboratory high-temperature process furnaces, mainly in the following fields:

Materials science: for the preparation and processing of novel materials, such as nanomaterials, ceramics, composites, etc.

Chemical synthesis: for chemical vapor deposition (CVD), vapor growth, catalyst activation, etc.

Physical research: used to study the high temperature properties of materials, phase transitions, heat treatment processes, etc.

- Semiconductor industry: used for the diffusion, oxidation, annealing and other processes of semiconductor materials.

Heat treatment: used for sintering, annealing, and reducing materials.

Custom description

Quartz tubes can be customized according to the specific needs of the laboratory to meet different experimental requirements.

Size customization: The length, diameter and wall thickness of the quartz tube can be customized according to the specifications of the experimental equipment and the size of the sample.

Shape customization: In addition to the common round tubes, special-shaped quartz tubes can also be customized according to experimental requirements.

Special performance customization: For example, for experiments that require special atmospheres, quartz tubes can be customized to withstand specific gas environments.

- Accessories customization: Special flanges, seals and other accessories can be equipped to ensure the airtightness and ease of operation of quartz tubes.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.