T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

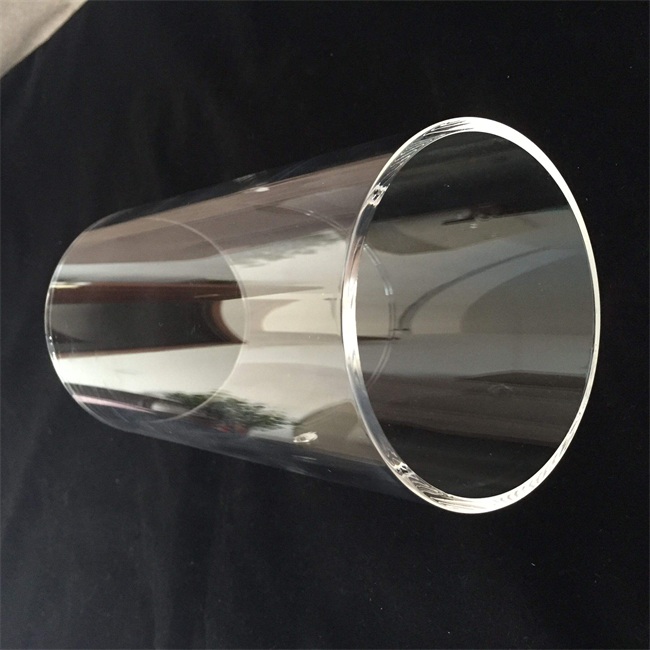

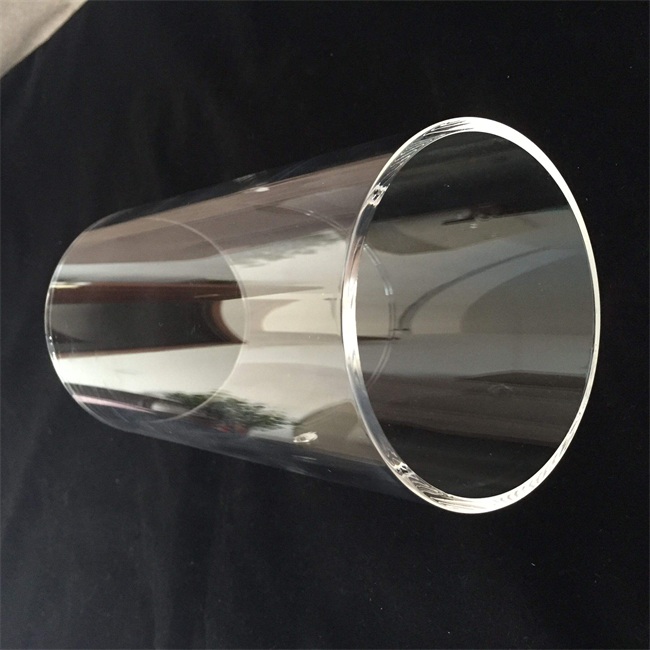

600mm diameter quartz tube

600mm diameter quartz tube is a large quartz glass product made of high-purity natural quartz sand through high-temperature melting and precision control molding process.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

600mm diameter quartz tube is a large quartz glass product made of high-purity natural quartz sand through high-temperature melting and precision control molding process. Its significant large aperture characteristics, combined with the excellent thermal, optical, and chemical properties of quartz materials themselves, make it an irreplaceable key foundational material in many high-end industrial fields and cutting-edge scientific experiments.

Core advantages and product features

This product strictly adheres to high-quality standards and has the following outstanding performance:

1. Excellent thermal stability

High temperature resistance: The softening point can reach up to 1730 ℃, and the long-term use temperature can reach 1200 ℃, which can withstand severe thermal shock.

Low thermal expansion coefficient: The thermal expansion coefficient is extremely low (about 5.5 × 10 ⁻⁷/℃), which is not easy to explode under rapid cooling and heating conditions, ensuring process safety.

2. Excellent optical performance

High transmittance: It has excellent transmittance in the broad spectral range from ultraviolet to infrared, especially for ultraviolet light, which far exceeds the transmittance of ordinary glass. It is an ideal window material for ultraviolet disinfection and photochemical reactions.

Optical uniformity: The material has no bubbles or stripes inside, ensuring that the light is transmitted without distortion and meeting the requirements of high-precision optical systems.

3. Excellent chemical purity and stability

High purity: Silicon dioxide (SiO ₂) content ≥ 99.99%, effectively reducing pollution to process materials at high temperatures.

Corrosion resistance: Except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acidic substances and has considerable corrosion resistance to alkaline solutions.

4. Excellent electrical insulation and vacuum performance

At room temperature, the resistance value can reach up to 1 × 10 ⊃1;⁶Ω· cm, making it an excellent high-temperature insulation material.

Good airtightness makes it an ideal chamber for high vacuum systems, maintaining a stable low-pressure environment.

Main application areas

The 600mm large-diameter quartz tube plays a core role in the following key areas due to its comprehensive advantages:

Semiconductor industry:

Application scenario: Used as furnace tubes for wafer oxidation, diffusion, and annealing processes.

Problem solving: Its high purity and high-temperature resistance provide a pollution-free and highly stable high-temperature environment for silicon wafer manufacturing, which is a key component to ensure chip performance and yield.

Photovoltaic new energy:

Application scenario: Insulation cover and carrier for polycrystalline silicon and monocrystalline silicon ingot furnaces.

Problem solving: Large caliber design meets the production needs of large-sized silicon ingots; High transparency allows infrared heating to penetrate through specific processes, achieving uniform heating and improving the quality of silicon ingots.

Optoelectronics and Lighting:

Application scenario: The casing of high-power metal halide lamps and ultraviolet sterilization lamps.

Problem solving: Able to withstand the high temperature of the arc and efficiently transmit specific wavelengths of ultraviolet light, while maintaining stable chemical properties to prevent reactions between the substances inside the lamp and the tube wall.

Research and Special Equipment:

Application scenarios: Large vacuum chambers, observation windows, CVD (chemical vapor deposition) equipment reaction chambers, precision optical platform support structures.

Problem solving: Provides customized transparent or load-bearing solutions that meet extreme conditions (high temperature, high vacuum, strong corrosion) for cutting-edge experiments and special equipment manufacturing.

The key problems we can solve

By choosing our 600mm diameter quartz tube, you will effectively tackle the following challenges:

1. The load-bearing problem of large-sized processes: solving the process requirements for batch or single processing of large-scale workpieces that traditional small-diameter quartz tubes cannot meet.

2. Pollution risk in high temperature environment: The high purity of the material itself greatly reduces product defects caused by impurities precipitation in sensitive processes (such as semiconductor doping).

3. Equipment failure caused by thermal stress: Excellent thermal shock stability avoids pipe cracking caused by frequent temperature rise and fall, prolongs equipment maintenance cycle, and improves production continuity.

4. Material matching in harsh environments: Provides reliable and long-lasting material selection for equipment that needs to operate in high temperature, high vacuum, strong corrosion, or specific spectral environments.

Customized service

We are well aware that standard products cannot meet all innovative needs. Therefore, we offer comprehensive customized services:

Size customization: Customized cutting with different wall thicknesses and lengths can be provided on a reference diameter of 600mm.

Shape processing: According to the equipment drawings, precision secondary processing such as opening, edging, sealing, bending, etc. are carried out.

Surface treatment: Provide surface treatment services such as sandblasting, sanding, and coating (such as anti reflective film, ITO film).

Performance enhancement: Specialized quartz tubes doped with specific elements (such as titanium and cerium) can be provided according to requirements to adjust UV transmittance or radiation resistance.

600mm diameter high-purity quartz tube is an indispensable basic material for modern high-tech industries. It is not only a tool for implementing specific processes, but also the cornerstone for ensuring product yield and promoting technological innovation. We are committed to providing our customers with quartz products and solutions that are stable in performance, complete in specifications, and support deep customization. We are your trusted partner in the fields of semiconductors, photovoltaics, optics, and scientific research.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.

600mm diameter quartz tube is a large quartz glass product made of high-purity natural quartz sand through high-temperature melting and precision control molding process. Its significant large aperture characteristics, combined with the excellent thermal, optical, and chemical properties of quartz materials themselves, make it an irreplaceable key foundational material in many high-end industrial fields and cutting-edge scientific experiments.

Core advantages and product features

This product strictly adheres to high-quality standards and has the following outstanding performance:

1. Excellent thermal stability

High temperature resistance: The softening point can reach up to 1730 ℃, and the long-term use temperature can reach 1200 ℃, which can withstand severe thermal shock.

Low thermal expansion coefficient: The thermal expansion coefficient is extremely low (about 5.5 × 10 ⁻⁷/℃), which is not easy to explode under rapid cooling and heating conditions, ensuring process safety.

2. Excellent optical performance

High transmittance: It has excellent transmittance in the broad spectral range from ultraviolet to infrared, especially for ultraviolet light, which far exceeds the transmittance of ordinary glass. It is an ideal window material for ultraviolet disinfection and photochemical reactions.

Optical uniformity: The material has no bubbles or stripes inside, ensuring that the light is transmitted without distortion and meeting the requirements of high-precision optical systems.

3. Excellent chemical purity and stability

High purity: Silicon dioxide (SiO ₂) content ≥ 99.99%, effectively reducing pollution to process materials at high temperatures.

Corrosion resistance: Except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acidic substances and has considerable corrosion resistance to alkaline solutions.

4. Excellent electrical insulation and vacuum performance

At room temperature, the resistance value can reach up to 1 × 10 ⊃1;⁶Ω· cm, making it an excellent high-temperature insulation material.

Good airtightness makes it an ideal chamber for high vacuum systems, maintaining a stable low-pressure environment.

Main application areas

The 600mm large-diameter quartz tube plays a core role in the following key areas due to its comprehensive advantages:

Semiconductor industry:

Application scenario: Used as furnace tubes for wafer oxidation, diffusion, and annealing processes.

Problem solving: Its high purity and high-temperature resistance provide a pollution-free and highly stable high-temperature environment for silicon wafer manufacturing, which is a key component to ensure chip performance and yield.

Photovoltaic new energy:

Application scenario: Insulation cover and carrier for polycrystalline silicon and monocrystalline silicon ingot furnaces.

Problem solving: Large caliber design meets the production needs of large-sized silicon ingots; High transparency allows infrared heating to penetrate through specific processes, achieving uniform heating and improving the quality of silicon ingots.

Optoelectronics and Lighting:

Application scenario: The casing of high-power metal halide lamps and ultraviolet sterilization lamps.

Problem solving: Able to withstand the high temperature of the arc and efficiently transmit specific wavelengths of ultraviolet light, while maintaining stable chemical properties to prevent reactions between the substances inside the lamp and the tube wall.

Research and Special Equipment:

Application scenarios: Large vacuum chambers, observation windows, CVD (chemical vapor deposition) equipment reaction chambers, precision optical platform support structures.

Problem solving: Provides customized transparent or load-bearing solutions that meet extreme conditions (high temperature, high vacuum, strong corrosion) for cutting-edge experiments and special equipment manufacturing.

The key problems we can solve

By choosing our 600mm diameter quartz tube, you will effectively tackle the following challenges:

1. The load-bearing problem of large-sized processes: solving the process requirements for batch or single processing of large-scale workpieces that traditional small-diameter quartz tubes cannot meet.

2. Pollution risk in high temperature environment: The high purity of the material itself greatly reduces product defects caused by impurities precipitation in sensitive processes (such as semiconductor doping).

3. Equipment failure caused by thermal stress: Excellent thermal shock stability avoids pipe cracking caused by frequent temperature rise and fall, prolongs equipment maintenance cycle, and improves production continuity.

4. Material matching in harsh environments: Provides reliable and long-lasting material selection for equipment that needs to operate in high temperature, high vacuum, strong corrosion, or specific spectral environments.

Customized service

We are well aware that standard products cannot meet all innovative needs. Therefore, we offer comprehensive customized services:

Size customization: Customized cutting with different wall thicknesses and lengths can be provided on a reference diameter of 600mm.

Shape processing: According to the equipment drawings, precision secondary processing such as opening, edging, sealing, bending, etc. are carried out.

Surface treatment: Provide surface treatment services such as sandblasting, sanding, and coating (such as anti reflective film, ITO film).

Performance enhancement: Specialized quartz tubes doped with specific elements (such as titanium and cerium) can be provided according to requirements to adjust UV transmittance or radiation resistance.

600mm diameter high-purity quartz tube is an indispensable basic material for modern high-tech industries. It is not only a tool for implementing specific processes, but also the cornerstone for ensuring product yield and promoting technological innovation. We are committed to providing our customers with quartz products and solutions that are stable in performance, complete in specifications, and support deep customization. We are your trusted partner in the fields of semiconductors, photovoltaics, optics, and scientific research.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.