T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

Quartz tube furnace accessories

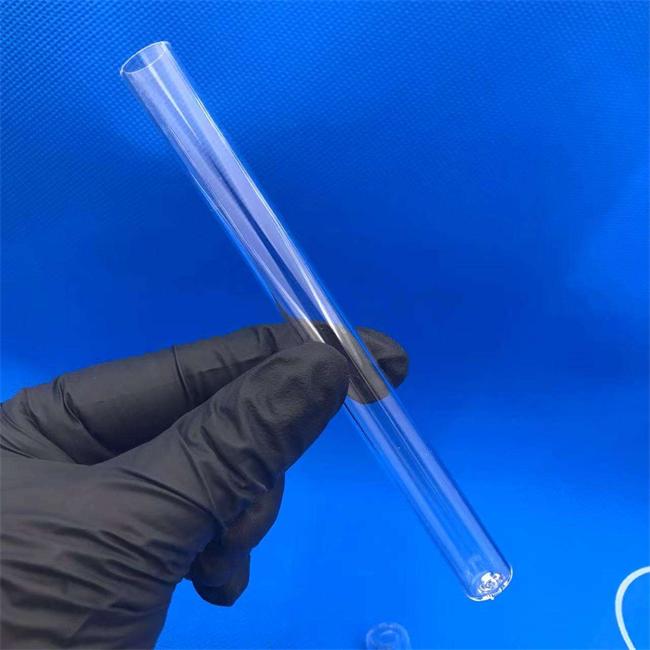

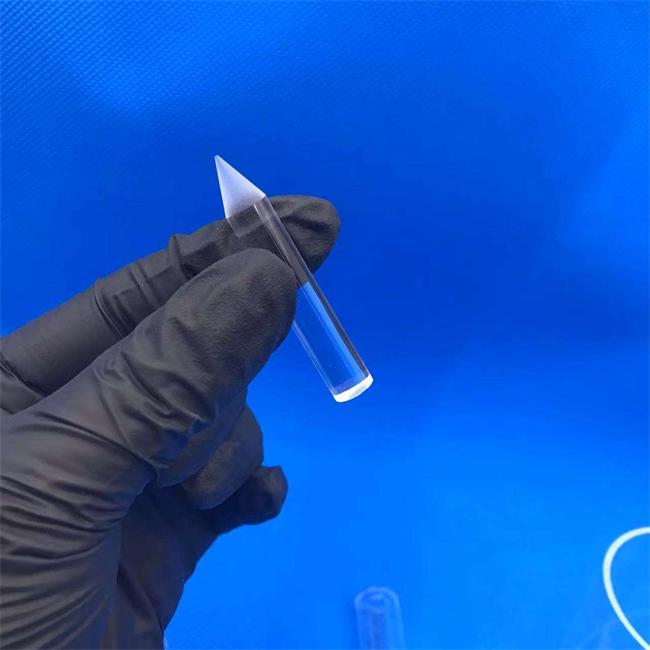

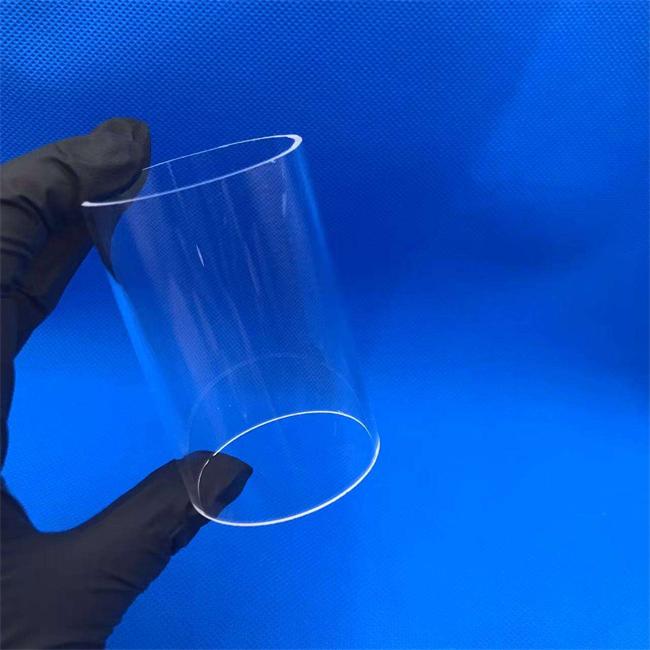

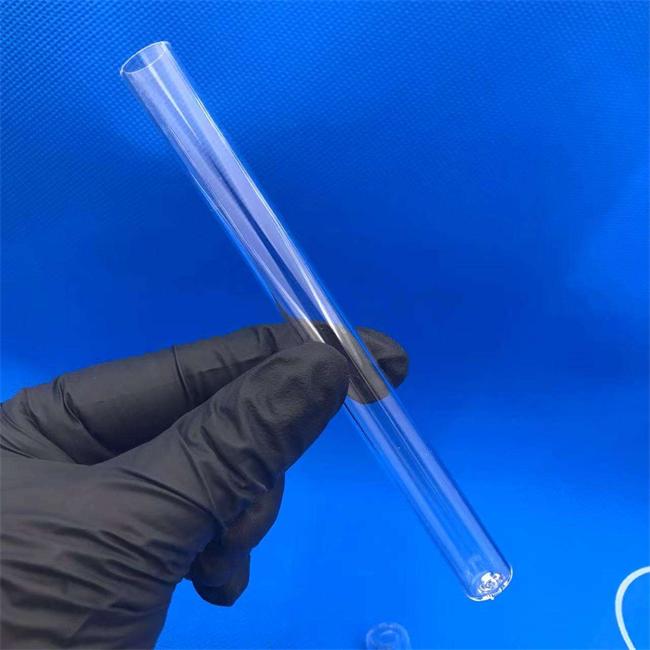

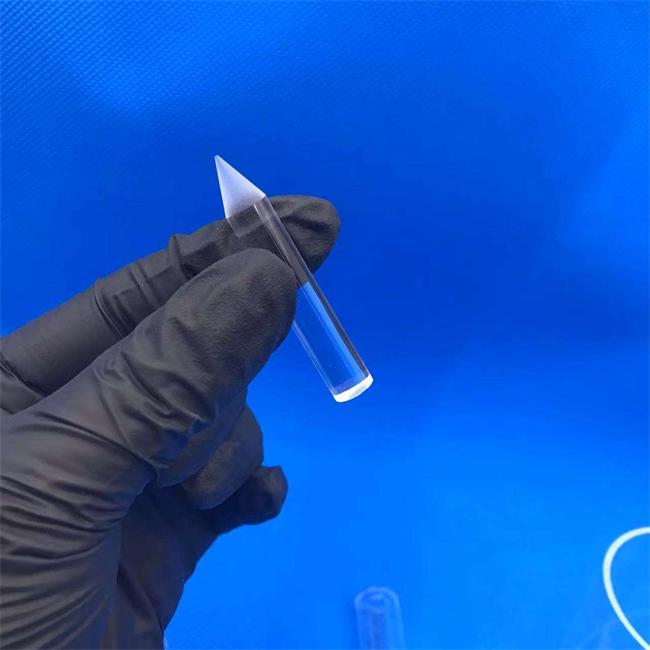

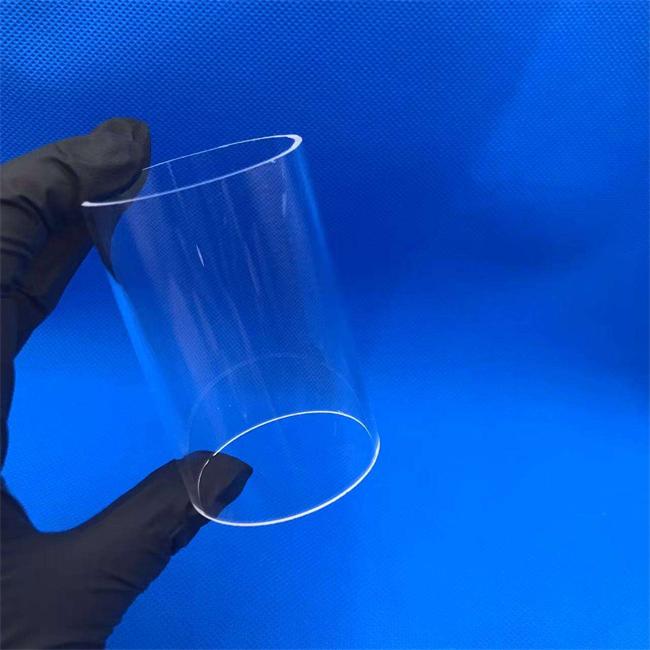

Quartz tube: straight tube, conical tube, flange tube, etc., suitable for high-temperature treatment such as semiconductor annealing, photovoltaic sintering, material synthesis, etc.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

Quartz tube furnace accessories

What core problems can quartz tube furnace accessories solve for you?

Q: In high-temperature experiments or production, ordinary materials are prone to deformation and sample contamination. How to ensure stability and purity?

Answer: Our high-purity quartz accessories have a temperature resistance of over 1200 ° C, a low coefficient of thermal expansion, no deformation at high temperatures, and strong chemical inertness to avoid contaminating materials.

Q: What should I do if I need quartz accessories with special sizes or shapes that cannot be met by standard products?

Answer: We provide full-size customization services, from quartz tubes with diameters ranging from 10mm to 300mm, irregular connectors to complex components, all of which can be processed according to the drawings to accurately match your furnace body.

Q: Quartz accessories are fragile, how to ensure long-term reliability?

Answer: We use selected high-purity quartz sand combined with precision annealing technology to improve thermal shock resistance and mechanical strength, and optimize structural design to extend service life.

Product series and application areas

-Quartz tube: straight tube, conical tube, flange tube, etc., suitable for high-temperature treatment such as semiconductor annealing, photovoltaic sintering, material synthesis, etc.

-Quartz boat and bracket: used to carry wafers, powders, and sheet-like samples, designed reasonably to ensure uniform thermal field.

-Quartz connectors and flanges: ensure the airtightness of the tube furnace and support operation in vacuum or atmospheric environments.

-Customized components: such as multi-channel quartz tubes, observation windows, airflow guidance devices, etc., to meet special process requirements.

Key advantage

-High purity material: SiO ₂ content ≥ 99.99%, trace elements controllable, ensuring accurate experimental data.

-Excellent thermal performance: high temperature resistance (up to 1300 ° C in the short term), low thermal expansion (5.5 × 10 ⁻⁷/° C), strong thermal shock resistance.

-Chemical stability: acid resistant (except hydrofluoric acid), metal slag resistant, suitable for corrosive environments.

-Precision machining: CNC cutting, laser drilling, flame polishing, with dimensional tolerances controlled within ± 0.2mm.

Specifications and Customization Services

-Standard size: Quartz tube inner diameter 10-200mm, length up to 2000mm, wall thickness 1-10mm.

-Customized support:

-Flexible size adjustment, supporting non-standard diameters, bending angles, and irregular openings.

-Surface treatment options: transparent, frosted, coating (such as anti crystalline coating).

-Accessory combination: Provide a complete solution of pipe fittings, flanges, and sealing rings.

-Quick response: Provide 3D drawing confirmation, with a small batch customization cycle of 15-20 days.

Problem solving and customer value

-Replace metal/ceramic: avoid high-temperature oxidation and metal pollution, and improve product yield.

-Extend equipment lifespan: High quality quartz reduces frequent replacement and lowers maintenance costs.

-Process optimization: Customized design improves airflow distribution, temperature uniformity, and enhances experimental/production efficiency.

Customer Application Case (Anonymous)

-Case 1: German New Materials Laboratory

Requirement: For high-temperature silicon carbide synthesis, a quartz boat that can withstand 1300 ° C and carbon erosion is required.

Solution: Customized thickened wall thickness+surface anti crystallization coating quartz boat, with no cracking or deformation after six months of use, resulting in a 12% increase in product purity.

-Case 2: Indian Photovoltaic Enterprises

Requirement: Quartz tube furnace is used for sintering solar cells, but the thermal uniformity of the original components is poor.

Solution: Design multi-channel airflow guided quartz tube, improve temperature uniformity from ± 15 ° C to ± 5 ° C, and reduce energy consumption by 8%.

-Case 3: American University Research Institute

Requirement: Special angle quartz connecting tube for in-situ observation experiments, requiring high transparency and airtightness.

Solution: Customized 30 ° bend tube+optical grade window, light transmittance>93%, vacuum sealing up to 10 ⁻⁵ Pa.

Whether in research and development laboratories or industrial production lines, reliable quartz tube furnace accessories are the cornerstone of high-temperature processes. We are committed to providing customers with high-temperature resistant, high-purity, and precision customized quartz solutions to help you achieve experimental success and improve production efficiency.

If you need detailed specification sheets, customized consultations, or quick quotes, please feel free to contact us at any time.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.

Quartz tube furnace accessories

What core problems can quartz tube furnace accessories solve for you?

Q: In high-temperature experiments or production, ordinary materials are prone to deformation and sample contamination. How to ensure stability and purity?

Answer: Our high-purity quartz accessories have a temperature resistance of over 1200 ° C, a low coefficient of thermal expansion, no deformation at high temperatures, and strong chemical inertness to avoid contaminating materials.

Q: What should I do if I need quartz accessories with special sizes or shapes that cannot be met by standard products?

Answer: We provide full-size customization services, from quartz tubes with diameters ranging from 10mm to 300mm, irregular connectors to complex components, all of which can be processed according to the drawings to accurately match your furnace body.

Q: Quartz accessories are fragile, how to ensure long-term reliability?

Answer: We use selected high-purity quartz sand combined with precision annealing technology to improve thermal shock resistance and mechanical strength, and optimize structural design to extend service life.

Product series and application areas

-Quartz tube: straight tube, conical tube, flange tube, etc., suitable for high-temperature treatment such as semiconductor annealing, photovoltaic sintering, material synthesis, etc.

-Quartz boat and bracket: used to carry wafers, powders, and sheet-like samples, designed reasonably to ensure uniform thermal field.

-Quartz connectors and flanges: ensure the airtightness of the tube furnace and support operation in vacuum or atmospheric environments.

-Customized components: such as multi-channel quartz tubes, observation windows, airflow guidance devices, etc., to meet special process requirements.

Key advantage

-High purity material: SiO ₂ content ≥ 99.99%, trace elements controllable, ensuring accurate experimental data.

-Excellent thermal performance: high temperature resistance (up to 1300 ° C in the short term), low thermal expansion (5.5 × 10 ⁻⁷/° C), strong thermal shock resistance.

-Chemical stability: acid resistant (except hydrofluoric acid), metal slag resistant, suitable for corrosive environments.

-Precision machining: CNC cutting, laser drilling, flame polishing, with dimensional tolerances controlled within ± 0.2mm.

Specifications and Customization Services

-Standard size: Quartz tube inner diameter 10-200mm, length up to 2000mm, wall thickness 1-10mm.

-Customized support:

-Flexible size adjustment, supporting non-standard diameters, bending angles, and irregular openings.

-Surface treatment options: transparent, frosted, coating (such as anti crystalline coating).

-Accessory combination: Provide a complete solution of pipe fittings, flanges, and sealing rings.

-Quick response: Provide 3D drawing confirmation, with a small batch customization cycle of 15-20 days.

Problem solving and customer value

-Replace metal/ceramic: avoid high-temperature oxidation and metal pollution, and improve product yield.

-Extend equipment lifespan: High quality quartz reduces frequent replacement and lowers maintenance costs.

-Process optimization: Customized design improves airflow distribution, temperature uniformity, and enhances experimental/production efficiency.

Customer Application Case (Anonymous)

-Case 1: German New Materials Laboratory

Requirement: For high-temperature silicon carbide synthesis, a quartz boat that can withstand 1300 ° C and carbon erosion is required.

Solution: Customized thickened wall thickness+surface anti crystallization coating quartz boat, with no cracking or deformation after six months of use, resulting in a 12% increase in product purity.

-Case 2: Indian Photovoltaic Enterprises

Requirement: Quartz tube furnace is used for sintering solar cells, but the thermal uniformity of the original components is poor.

Solution: Design multi-channel airflow guided quartz tube, improve temperature uniformity from ± 15 ° C to ± 5 ° C, and reduce energy consumption by 8%.

-Case 3: American University Research Institute

Requirement: Special angle quartz connecting tube for in-situ observation experiments, requiring high transparency and airtightness.

Solution: Customized 30 ° bend tube+optical grade window, light transmittance>93%, vacuum sealing up to 10 ⁻⁵ Pa.

Whether in research and development laboratories or industrial production lines, reliable quartz tube furnace accessories are the cornerstone of high-temperature processes. We are committed to providing customers with high-temperature resistant, high-purity, and precision customized quartz solutions to help you achieve experimental success and improve production efficiency.

If you need detailed specification sheets, customized consultations, or quick quotes, please feel free to contact us at any time.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.