T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

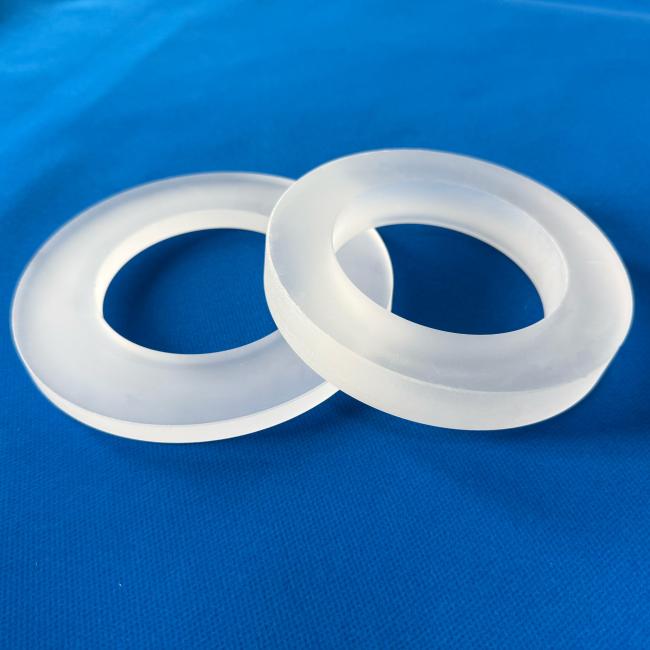

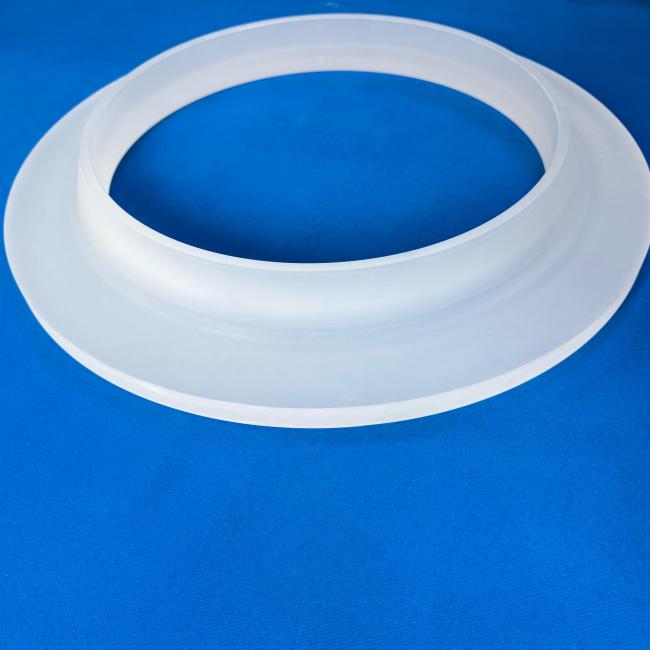

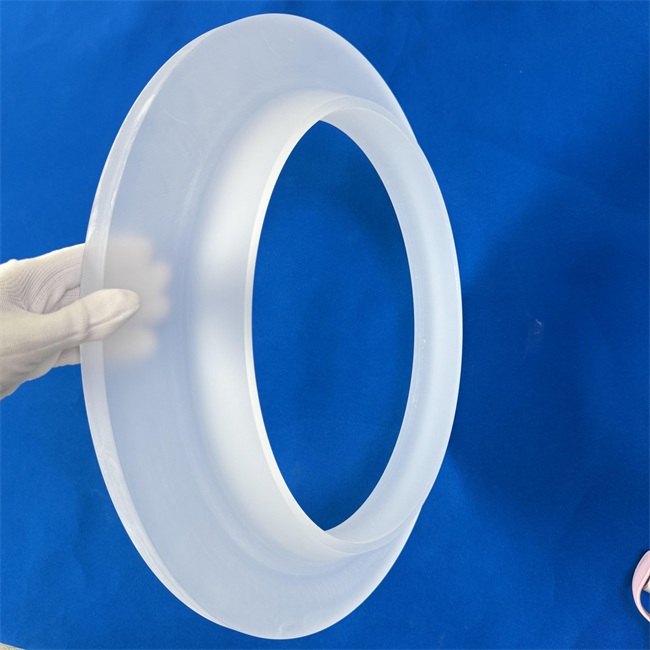

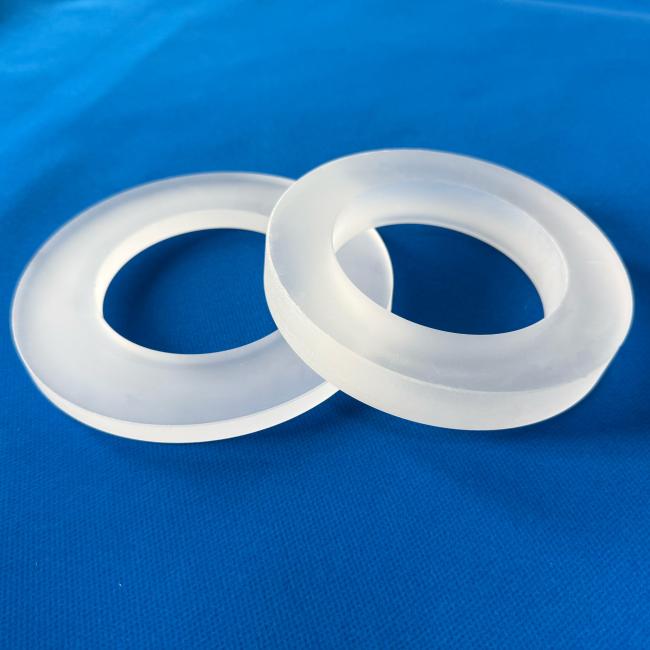

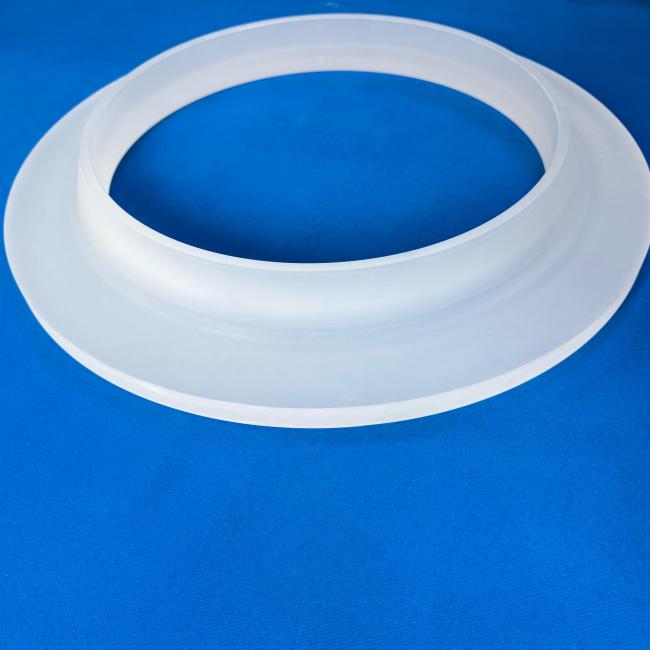

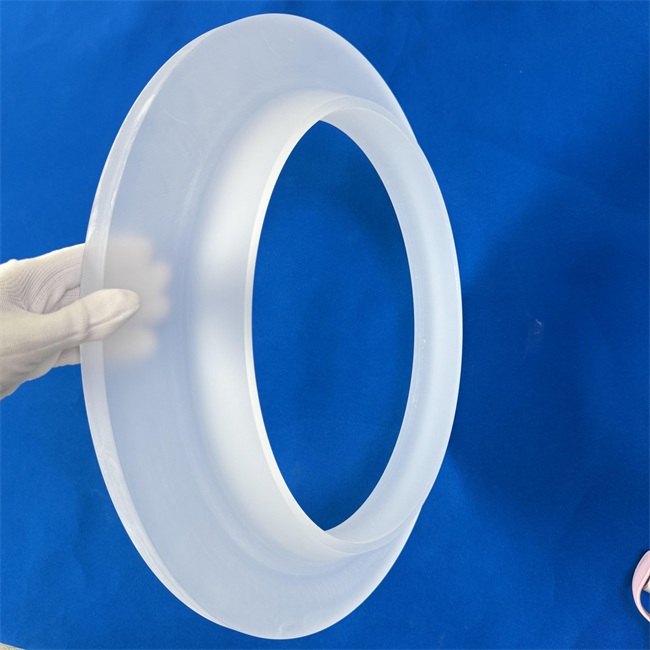

Translucent circular quartz flange

Translucent ring quartz flange is a kind of ring connecting part made of high-precision fused silica material, which has excellent thermal stability, chemical inertia and optical characteristics.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

Translucent ring quartz flange

What can the circular quartz flange solve for your project?

Q: How to ensure absolute sealing and long-term stability of pipeline connections in high temperature, high pressure, or highly corrosive environments?

Answer: The translucent annular quartz flange is made of high-purity fused silica, with a temperature tolerance of more than 1100 ℃, a very low coefficient of thermal expansion, and almost no deformation under severe temperature difference, which perfectly solves the problem of seal failure under high temperature environment.

Q: How to achieve a clean connection that is both corrosion-resistant and non polluting in semiconductor, photovoltaic, or optical equipment?

Answer: Quartz material has excellent chemical inertness and is almost not corroded by any acid other than hydrofluoric acid. Its surface is smooth without micropores and will not adsorb or release pollutants, ensuring the high purity of the process medium.

Q: How can traditional metal flanges balance sealing and visualization requirements when observing the fluid state inside pipelines?

Answer: The semi transparent annular quartz flange maintains mechanical strength while providing excellent optical transparency (transparency of about 93%), allowing real-time visual or sensor monitoring of internal process status without the need for additional observation windows.

Translucent ring quartz flange is a kind of ring connecting part made of high-precision fused silica material, which has excellent thermal stability, chemical inertia and optical characteristics. As a professional manufacturer in the field of customized quartz products, we provide high standard and high-performance quartz solutions for global industrial customers, widely used in fields such as semiconductors, photovoltaics, chemical engineering, optoelectronics, and scientific research experiments.

Core product advantages

1. Excellent material performance

-High purity material: fused silica with purity above 99.99% is used to ensure extremely low impurity content

-Excellent thermal stability: With an extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), it can withstand rapid changes in high temperature up to 1200 ℃ without breaking

-Chemical inertness: Resistant to acid and alkali corrosion, hardly reacts with any chemical substances except hydrofluoric acid and hot phosphoric acid

-Optical properties: The semi transparent structure allows visible and ultraviolet light to pass through, making it easy to monitor the process

-Electrical insulation: high resistivity, suitable for high voltage and high frequency application environments

2. Precision machining technology

-CNC precision machining: using computer numerical control machine tools to ensure dimensional accuracy of ± 0.1mm

-Laser cutting technology: achieving complex shapes and precise aperture processing

-Flame polishing treatment: Surface smoothness Ra ≤ 0.8 μ m, reducing the risk of particle contamination

-Strict quality control: Each batch of products undergoes size, flatness, parallelism, and purity testing

Technical specifications and customized services

Standard specification range

-Outer diameter size: 50mm to 600mm (supports customization for larger sizes)

-Inner diameter size: 20mm to 550mm

-Thickness range: 3mm to 30mm

-Tolerance control: outer diameter ± 0.1mm, inner diameter ± 0.05mm, thickness ± 0.05mm

-Surface smoothness: Polishing, sanding, or special coating treatment can be provided according to application requirements

Comprehensive customization capability

-Size customization: non-standard sizes, irregular holes, special thicknesses

-Structural design: Integrated card slots, grooves, threaded holes, positioning holes and other complex structures

-Performance optimization: Adjust transmittance, thermal conductivity, or mechanical strength according to application scenarios

-Accessory matching: Provide a complete connection system including matching quartz bolts, washers, observation windows, etc

Key industry issues addressed

1. Semiconductor manufacturing

-Challenge: Metal pollution and particle generation in high-temperature processes

-Solution: The extremely high purity of quartz material avoids contaminating the wafer, and the smooth surface reduces particle shedding

-Effect: Improve chip yield and extend maintenance cycle

2. Photovoltaic industry

-Challenge: High temperature corrosion and thermal stress rupture in crystal growth furnace

-Solution: Excellent thermal stability and chemical inertness of quartz flanges

-Effect: Extend furnace life and reduce production costs

3. Chemical processing

-Challenge: Equipment sealing and observation requirements in highly corrosive environments

-Solution: Corrosion resistant semi transparent quartz flange

-Effect: Achieve safe observation and long-term stable sealing

4. Scientific research experimental equipment

-Challenge: Customized requirements under special experimental conditions

-Solution: Flexible customized design services

-Effect: Accurately match experimental parameters to ensure data accuracy

Why choose us

1. Professional manufacturing capability

-Focused on quartz product production for 18 years, with complete industry chain control capability

-Independently developing quartz melting technology to ensure material consistency and stability

-Introducing precision machining equipment from Germany and Japan to ensure product accuracy

2. Global service experience

-Our products are exported to 35 countries and serve over 500 industrial customers

-Multi language technical support team (English, German, Japanese, Korean)

-Familiar with industry standards and certification requirements in various countries

3. Quick response service

-Standard product delivery time of 7-15 days

-No minimum order quantity

-Technical support responds within 48 hours

Application Cases

Case 1: European semiconductor equipment manufacturer

-Requirement: Quartz window flange for plasma etching equipment, requiring high purity and flatness

-Solution: Customized semi transparent quartz flange with a diameter of 380mm and a thickness of 12mm, integrated with 16 precision positioning holes

-Result: The product has passed strict customer testing, replaced the original supplier, and maintained a zero return record for three consecutive years

Case 2: American Solar Energy Research Institute

-Requirement: The observation port flange of the crystal silicon growth furnace needs to withstand the impact of a temperature difference of 1400 ℃

-Solution: Develop semi transparent quartz flanges with special heat treatment to optimize thermal stress distribution

-Result: The service life has been extended by 40%, and the research team has successfully observed the key process of crystal growth

Case 3: Asian Chemical Enterprises

-Requirement: Strong acid reaction vessel observation flange, corrosion-resistant and easy to disassemble and maintain

-Solution: Customized quartz flange system with quick connect structure, with special surface treatment to enhance corrosion resistance

-Result: 60% reduction in equipment maintenance time and significant improvement in safety

![]()

We are well aware that every industrial application has its unique needs, which is why we focus on customized solutions. Whether you are seeking standard sized semi transparent ring quartz flanges or special designs that require complete customization, our engineering team can provide professional support.

Contact our quartz solution experts immediately for design consultation and sample evaluation, and work together to create quartz components that meet your precise requirements. Let us transform your high requirements into high-performance products to assist in your process innovation and efficiency improvement.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.

Translucent ring quartz flange

What can the circular quartz flange solve for your project?

Q: How to ensure absolute sealing and long-term stability of pipeline connections in high temperature, high pressure, or highly corrosive environments?

Answer: The translucent annular quartz flange is made of high-purity fused silica, with a temperature tolerance of more than 1100 ℃, a very low coefficient of thermal expansion, and almost no deformation under severe temperature difference, which perfectly solves the problem of seal failure under high temperature environment.

Q: How to achieve a clean connection that is both corrosion-resistant and non polluting in semiconductor, photovoltaic, or optical equipment?

Answer: Quartz material has excellent chemical inertness and is almost not corroded by any acid other than hydrofluoric acid. Its surface is smooth without micropores and will not adsorb or release pollutants, ensuring the high purity of the process medium.

Q: How can traditional metal flanges balance sealing and visualization requirements when observing the fluid state inside pipelines?

Answer: The semi transparent annular quartz flange maintains mechanical strength while providing excellent optical transparency (transparency of about 93%), allowing real-time visual or sensor monitoring of internal process status without the need for additional observation windows.

Translucent ring quartz flange is a kind of ring connecting part made of high-precision fused silica material, which has excellent thermal stability, chemical inertia and optical characteristics. As a professional manufacturer in the field of customized quartz products, we provide high standard and high-performance quartz solutions for global industrial customers, widely used in fields such as semiconductors, photovoltaics, chemical engineering, optoelectronics, and scientific research experiments.

Core product advantages

1. Excellent material performance

-High purity material: fused silica with purity above 99.99% is used to ensure extremely low impurity content

-Excellent thermal stability: With an extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), it can withstand rapid changes in high temperature up to 1200 ℃ without breaking

-Chemical inertness: Resistant to acid and alkali corrosion, hardly reacts with any chemical substances except hydrofluoric acid and hot phosphoric acid

-Optical properties: The semi transparent structure allows visible and ultraviolet light to pass through, making it easy to monitor the process

-Electrical insulation: high resistivity, suitable for high voltage and high frequency application environments

2. Precision machining technology

-CNC precision machining: using computer numerical control machine tools to ensure dimensional accuracy of ± 0.1mm

-Laser cutting technology: achieving complex shapes and precise aperture processing

-Flame polishing treatment: Surface smoothness Ra ≤ 0.8 μ m, reducing the risk of particle contamination

-Strict quality control: Each batch of products undergoes size, flatness, parallelism, and purity testing

Technical specifications and customized services

Standard specification range

-Outer diameter size: 50mm to 600mm (supports customization for larger sizes)

-Inner diameter size: 20mm to 550mm

-Thickness range: 3mm to 30mm

-Tolerance control: outer diameter ± 0.1mm, inner diameter ± 0.05mm, thickness ± 0.05mm

-Surface smoothness: Polishing, sanding, or special coating treatment can be provided according to application requirements

Comprehensive customization capability

-Size customization: non-standard sizes, irregular holes, special thicknesses

-Structural design: Integrated card slots, grooves, threaded holes, positioning holes and other complex structures

-Performance optimization: Adjust transmittance, thermal conductivity, or mechanical strength according to application scenarios

-Accessory matching: Provide a complete connection system including matching quartz bolts, washers, observation windows, etc

Key industry issues addressed

1. Semiconductor manufacturing

-Challenge: Metal pollution and particle generation in high-temperature processes

-Solution: The extremely high purity of quartz material avoids contaminating the wafer, and the smooth surface reduces particle shedding

-Effect: Improve chip yield and extend maintenance cycle

2. Photovoltaic industry

-Challenge: High temperature corrosion and thermal stress rupture in crystal growth furnace

-Solution: Excellent thermal stability and chemical inertness of quartz flanges

-Effect: Extend furnace life and reduce production costs

3. Chemical processing

-Challenge: Equipment sealing and observation requirements in highly corrosive environments

-Solution: Corrosion resistant semi transparent quartz flange

-Effect: Achieve safe observation and long-term stable sealing

4. Scientific research experimental equipment

-Challenge: Customized requirements under special experimental conditions

-Solution: Flexible customized design services

-Effect: Accurately match experimental parameters to ensure data accuracy

Why choose us

1. Professional manufacturing capability

-Focused on quartz product production for 18 years, with complete industry chain control capability

-Independently developing quartz melting technology to ensure material consistency and stability

-Introducing precision machining equipment from Germany and Japan to ensure product accuracy

2. Global service experience

-Our products are exported to 35 countries and serve over 500 industrial customers

-Multi language technical support team (English, German, Japanese, Korean)

-Familiar with industry standards and certification requirements in various countries

3. Quick response service

-Standard product delivery time of 7-15 days

-No minimum order quantity

-Technical support responds within 48 hours

Application Cases

Case 1: European semiconductor equipment manufacturer

-Requirement: Quartz window flange for plasma etching equipment, requiring high purity and flatness

-Solution: Customized semi transparent quartz flange with a diameter of 380mm and a thickness of 12mm, integrated with 16 precision positioning holes

-Result: The product has passed strict customer testing, replaced the original supplier, and maintained a zero return record for three consecutive years

Case 2: American Solar Energy Research Institute

-Requirement: The observation port flange of the crystal silicon growth furnace needs to withstand the impact of a temperature difference of 1400 ℃

-Solution: Develop semi transparent quartz flanges with special heat treatment to optimize thermal stress distribution

-Result: The service life has been extended by 40%, and the research team has successfully observed the key process of crystal growth

Case 3: Asian Chemical Enterprises

-Requirement: Strong acid reaction vessel observation flange, corrosion-resistant and easy to disassemble and maintain

-Solution: Customized quartz flange system with quick connect structure, with special surface treatment to enhance corrosion resistance

-Result: 60% reduction in equipment maintenance time and significant improvement in safety

![]()

We are well aware that every industrial application has its unique needs, which is why we focus on customized solutions. Whether you are seeking standard sized semi transparent ring quartz flanges or special designs that require complete customization, our engineering team can provide professional support.

Contact our quartz solution experts immediately for design consultation and sample evaluation, and work together to create quartz components that meet your precise requirements. Let us transform your high requirements into high-performance products to assist in your process innovation and efficiency improvement.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.