T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

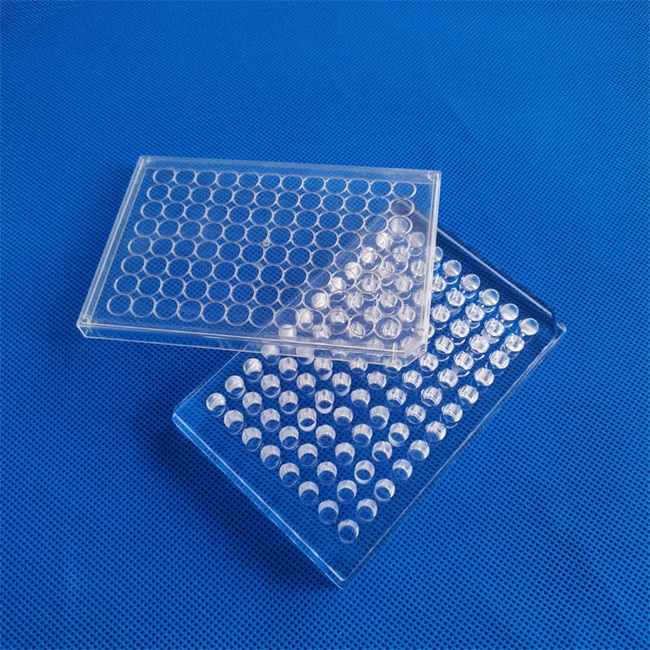

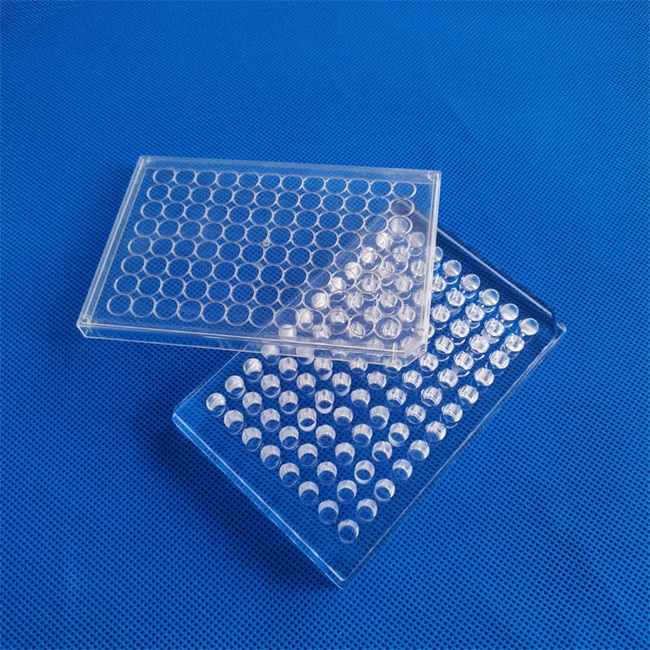

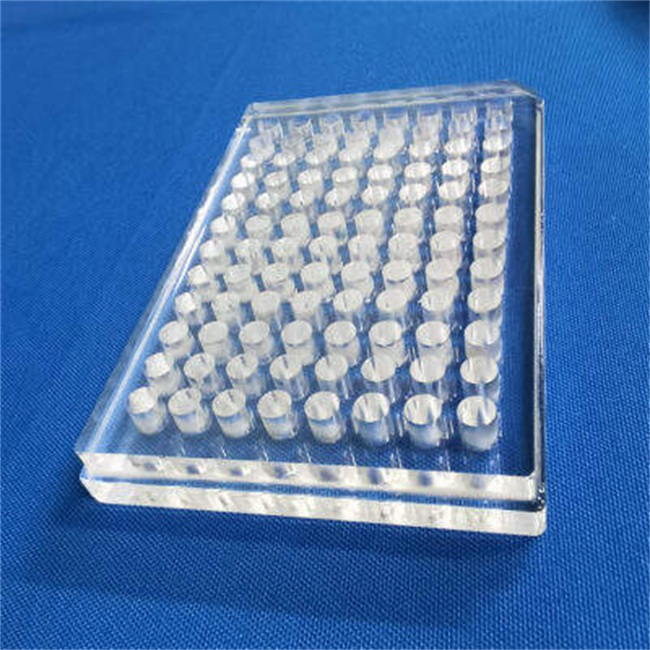

96 well optical quartz plate

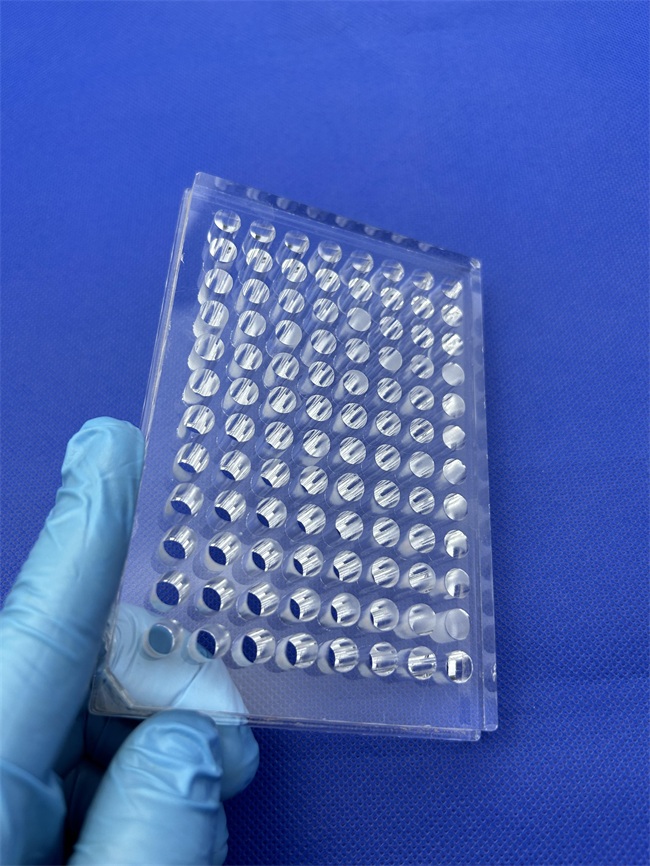

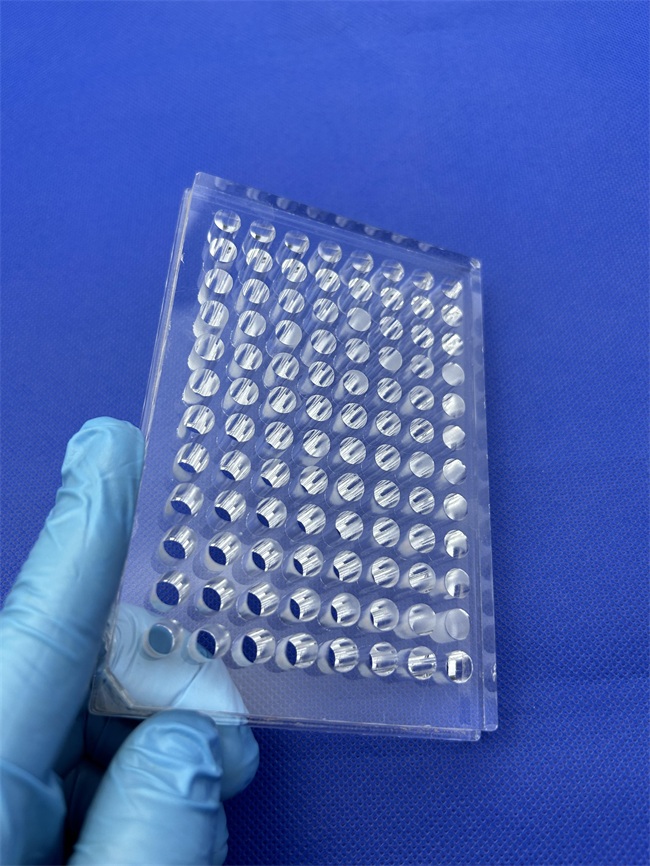

The 96-well optical quartz plate is a high-end microplate precisely processed from high-purity fused quartz material.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

Optical quartz plate with 96 wells

The 96-well optical quartz plate is a high-end microplate precisely processed from high-purity fused quartz material. It perfectly combines the universal format of standard 96-well plates with the outstanding performance of optical quartz, and is specially designed for application scenarios with strict requirements for ultraviolet transmittance, thermal stability and chemical inertness.

Core material advantages

High ultraviolet transmittance: It has extremely high transmittance across a wide spectral range from deep ultraviolet (DUV) to near-infrared (NIR), especially performing exceptionally well in the 180nm - 250nm band, far exceeding that of ordinary glass or plastic microplates.

Extremely low autofluorescence: The material has an extremely high purity, which can minimize the background fluorescence interference generated by the plate itself, thereby significantly improving the signal-to-noise ratio of the detection.

Excellent thermal stability: With an extremely low coefficient of thermal expansion, it can withstand drastic temperature changes (from high-temperature baking to rapid cooling) without deformation or cracking, ensuring the stability of the well size.

Outstanding chemical inertness: Resistant to strong acids, strong alkalis and organic solvents, easy to clean and reuse, and will not contaminate samples due to chemical reactions.

What problems can this product solve?

In the fields of life sciences, drug screening and analytical chemistry, researchers often encounter the following challenges, and the 96-well optical quartz plate is precisely designed to address these issues:

1. Solve the absorption problem in the ultraviolet band:

Question: When determining the concentration of proteins and nucleic acids (DNA/RNA) or conducting enzyme kinetics studies, it is often necessary to carry out detection at ultraviolet wavelengths such as 260nm or 280nm. Ordinary plastic or glass microplates will strongly absorb ultraviolet light in this band, resulting in weak signals or even undetectable ones.

Solution: Optical quartz plates have an extremely high light transmittance in the ultraviolet region, ensuring the effective transmission of ultraviolet light and obtaining accurate and reliable absorbance or fluorescence readings.

2. Solve the problem of background fluorescence interference:

In highly sensitive fluorescence detections (such as cell analysis, ELISA, FRET), the autofluorescence of the plates themselves can create a relatively high background noise, masking weak positive signals and affecting the sensitivity and accuracy of the detection.

Solution: The extremely low autofluorescence property of quartz material can minimize background interference, thereby significantly enhancing the signal-to-noise ratio and enabling you to detect the signals of low-abundance targets more clearly.

3. Addressing stability issues in high-temperature and corrosive environments:

Question: Some experimental procedures involve high-temperature treatment (such as post-PCR analysis), cleaning with strong acids or bases, or the use of organic solvents. Under such circumstances, ordinary microplates may deform, dissolve, or release impurities.

Solution: The outstanding thermal stability and chemical inertness of optical quartz plates enable them to withstand harsh experimental conditions, ensuring the smooth progress of the experimental process and the reliability of the results, and support multiple reuses to reduce costs.

4. Solving compatibility issues in high-throughput screening:

Question: A device is needed that not only meets the requirements of precise optical inspection but also can be seamlessly integrated into an automated workstation.

Solution: It adopts a standard 96-well plate design, which can directly replace conventional microplates without any changes to the automation program, achieving a smooth transition from routine inspection to high-end optical inspection.

Main application fields

The 96-well optical quartz plate, with its unique performance, plays an irreplaceable role in the following fields

Ultraviolet-visible spectrophotometry

Quantitative analysis of nucleic acids (DNA/RNA)

Protein concentration determination (Bradford, BCA method, etc.)

Enzyme kinetics research

Fluorescence spectroscopy analysis

High-intensity fluorescence detection

Time-resolved fluorescence (TRF

Cell viability and proliferation analysis

Reporter gene testing

Drug screening and development

High-throughput drug Screening (HTS

Research on target-ligand interactions

Analytical Chemistry and Environmental Monitoring

All kinds of chemical analyses that require ultraviolet detection

Test corrosive samples

Academic Research and Industrial QC

Any scientific research and quality control process that has high requirements for optical performance, thermal stability and chemical stability.

Customized service

We are well aware that standard products may not meet the unique needs of all customers. Therefore, we offer flexible and diverse customized services, aiming to create an exclusive solution that best meets your experimental needs.

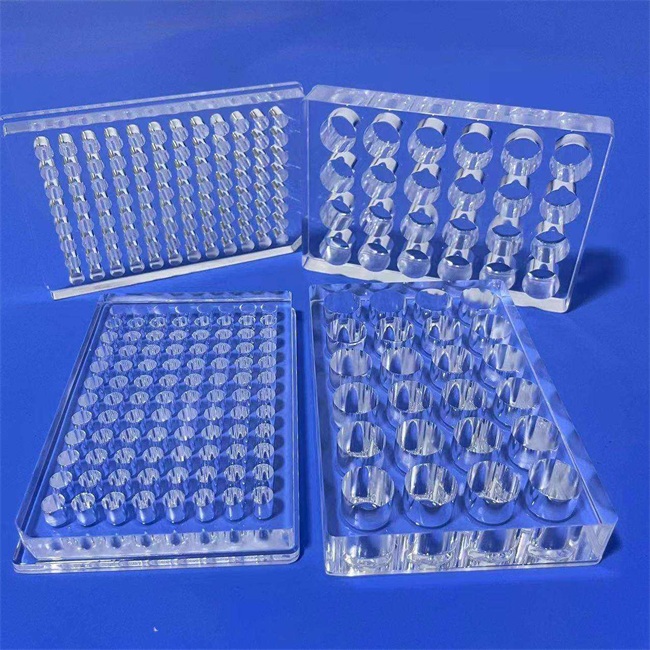

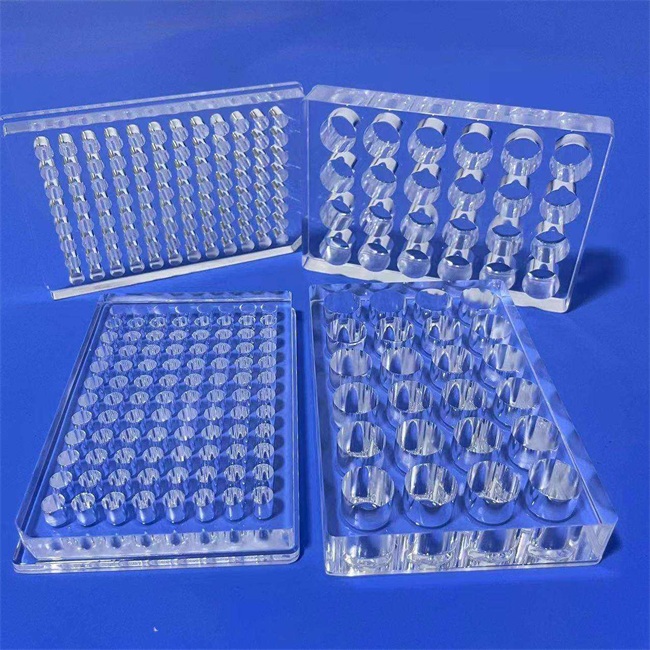

Customized orifice plate size and shape

In addition to the standard 96-well, we can also customize different specifications such as 24-well, 48-well, 384-well and even 1536-well.

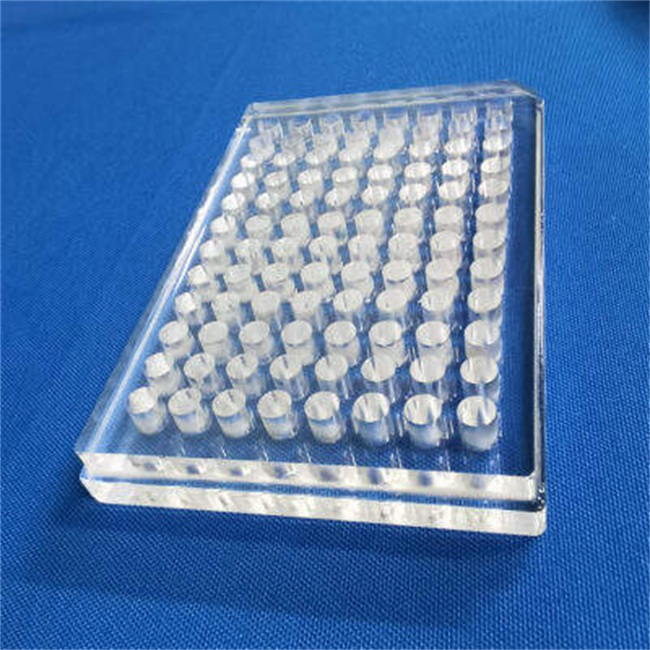

Customizable circular, square or special-shaped well bottoms are available to meet the requirements of specific optical systems (such as flat bottom, round bottom, conical bottom).

Optical performance customization

Coating service: We offer anti-reflection coatings (AR coatings) to further reduce reflection and enhance light transmittance at specific wavelengths, such as the ultraviolet and visible light regions. Other functional coatings can also be provided.

Customized surface treatment

Hydrophilic/hydrophobic treatment: According to the experimental requirements, the inner wall of the well plate is surface treated to improve or control the wettability of the liquid.

Surface functionalization: Provide surface activation services to facilitate subsequent coating and fixation of proteins, nucleic acids or specific molecules.

Material and thickness customization

Different grades of quartz materials can be recommended based on your budget and performance requirements.

The specific thickness of the board body and bottom can be customized to meet the requirements of special mechanical strength or optical path length.

The 96-well optical quartz plate is not only an experimental consumable but also a key tool for enhancing the quality and efficiency of your experimental data. It opens up new possibilities for high-end scientific research and industrial applications by addressing core pain points such as ultraviolet absorption, background fluorescence, and thermochemical stability. If you are looking for a reliable high-throughput optical inspection platform or are interested in the above-mentioned customized services, please feel free to contact us at any time. Our technical team will be more than happy to serve you.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.

Optical quartz plate with 96 wells

The 96-well optical quartz plate is a high-end microplate precisely processed from high-purity fused quartz material. It perfectly combines the universal format of standard 96-well plates with the outstanding performance of optical quartz, and is specially designed for application scenarios with strict requirements for ultraviolet transmittance, thermal stability and chemical inertness.

Core material advantages

High ultraviolet transmittance: It has extremely high transmittance across a wide spectral range from deep ultraviolet (DUV) to near-infrared (NIR), especially performing exceptionally well in the 180nm - 250nm band, far exceeding that of ordinary glass or plastic microplates.

Extremely low autofluorescence: The material has an extremely high purity, which can minimize the background fluorescence interference generated by the plate itself, thereby significantly improving the signal-to-noise ratio of the detection.

Excellent thermal stability: With an extremely low coefficient of thermal expansion, it can withstand drastic temperature changes (from high-temperature baking to rapid cooling) without deformation or cracking, ensuring the stability of the well size.

Outstanding chemical inertness: Resistant to strong acids, strong alkalis and organic solvents, easy to clean and reuse, and will not contaminate samples due to chemical reactions.

What problems can this product solve?

In the fields of life sciences, drug screening and analytical chemistry, researchers often encounter the following challenges, and the 96-well optical quartz plate is precisely designed to address these issues:

1. Solve the absorption problem in the ultraviolet band:

Question: When determining the concentration of proteins and nucleic acids (DNA/RNA) or conducting enzyme kinetics studies, it is often necessary to carry out detection at ultraviolet wavelengths such as 260nm or 280nm. Ordinary plastic or glass microplates will strongly absorb ultraviolet light in this band, resulting in weak signals or even undetectable ones.

Solution: Optical quartz plates have an extremely high light transmittance in the ultraviolet region, ensuring the effective transmission of ultraviolet light and obtaining accurate and reliable absorbance or fluorescence readings.

2. Solve the problem of background fluorescence interference:

In highly sensitive fluorescence detections (such as cell analysis, ELISA, FRET), the autofluorescence of the plates themselves can create a relatively high background noise, masking weak positive signals and affecting the sensitivity and accuracy of the detection.

Solution: The extremely low autofluorescence property of quartz material can minimize background interference, thereby significantly enhancing the signal-to-noise ratio and enabling you to detect the signals of low-abundance targets more clearly.

3. Addressing stability issues in high-temperature and corrosive environments:

Question: Some experimental procedures involve high-temperature treatment (such as post-PCR analysis), cleaning with strong acids or bases, or the use of organic solvents. Under such circumstances, ordinary microplates may deform, dissolve, or release impurities.

Solution: The outstanding thermal stability and chemical inertness of optical quartz plates enable them to withstand harsh experimental conditions, ensuring the smooth progress of the experimental process and the reliability of the results, and support multiple reuses to reduce costs.

4. Solving compatibility issues in high-throughput screening:

Question: A device is needed that not only meets the requirements of precise optical inspection but also can be seamlessly integrated into an automated workstation.

Solution: It adopts a standard 96-well plate design, which can directly replace conventional microplates without any changes to the automation program, achieving a smooth transition from routine inspection to high-end optical inspection.

Main application fields

The 96-well optical quartz plate, with its unique performance, plays an irreplaceable role in the following fields

Ultraviolet-visible spectrophotometry

Quantitative analysis of nucleic acids (DNA/RNA)

Protein concentration determination (Bradford, BCA method, etc.)

Enzyme kinetics research

Fluorescence spectroscopy analysis

High-intensity fluorescence detection

Time-resolved fluorescence (TRF

Cell viability and proliferation analysis

Reporter gene testing

Drug screening and development

High-throughput drug Screening (HTS

Research on target-ligand interactions

Analytical Chemistry and Environmental Monitoring

All kinds of chemical analyses that require ultraviolet detection

Test corrosive samples

Academic Research and Industrial QC

Any scientific research and quality control process that has high requirements for optical performance, thermal stability and chemical stability.

Customized service

We are well aware that standard products may not meet the unique needs of all customers. Therefore, we offer flexible and diverse customized services, aiming to create an exclusive solution that best meets your experimental needs.

Customized orifice plate size and shape

In addition to the standard 96-well, we can also customize different specifications such as 24-well, 48-well, 384-well and even 1536-well.

Customizable circular, square or special-shaped well bottoms are available to meet the requirements of specific optical systems (such as flat bottom, round bottom, conical bottom).

Optical performance customization

Coating service: We offer anti-reflection coatings (AR coatings) to further reduce reflection and enhance light transmittance at specific wavelengths, such as the ultraviolet and visible light regions. Other functional coatings can also be provided.

Customized surface treatment

Hydrophilic/hydrophobic treatment: According to the experimental requirements, the inner wall of the well plate is surface treated to improve or control the wettability of the liquid.

Surface functionalization: Provide surface activation services to facilitate subsequent coating and fixation of proteins, nucleic acids or specific molecules.

Material and thickness customization

Different grades of quartz materials can be recommended based on your budget and performance requirements.

The specific thickness of the board body and bottom can be customized to meet the requirements of special mechanical strength or optical path length.

The 96-well optical quartz plate is not only an experimental consumable but also a key tool for enhancing the quality and efficiency of your experimental data. It opens up new possibilities for high-end scientific research and industrial applications by addressing core pain points such as ultraviolet absorption, background fluorescence, and thermochemical stability. If you are looking for a reliable high-throughput optical inspection platform or are interested in the above-mentioned customized services, please feel free to contact us at any time. Our technical team will be more than happy to serve you.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.