T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

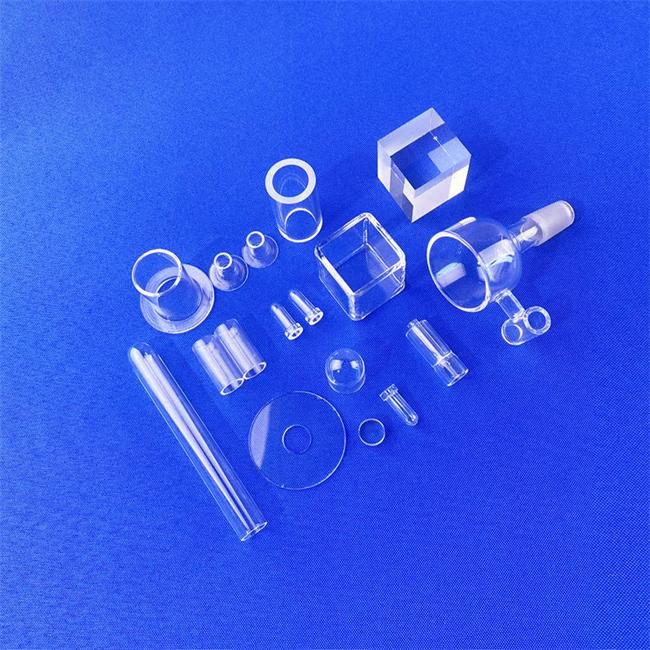

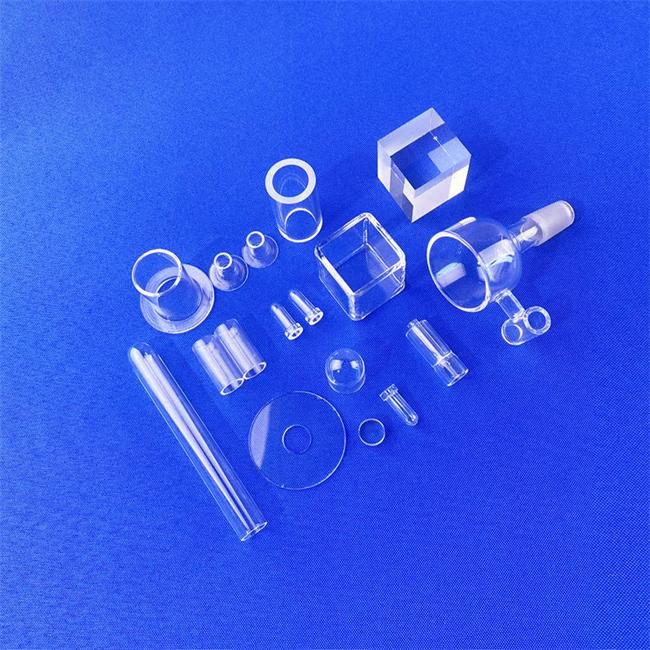

High purity quartz sample tube

High purity quartz sample tube is a transparent or semi transparent tubular product made from natural crystal or high-purity silica sand through high-temperature melting, precision molding, and post-treatment.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

High purity quartz sample tube

Q: Are you looking for a material that can withstand extreme high temperatures (up to 1200 ° C or above), has extremely stable chemical properties, and almost does not contaminate sensitive samples or reactions?

Answer: Our high-purity quartz sample tube is designed for this purpose. It solves the core problems in the fields of semiconductors, photovoltaics, fiber preform, high-end laboratory analysis, etc. - the pollution risk caused by insufficient material purity, equipment failure caused by poor thermal stability, and compatibility issues caused by non customized sizes.

Q: Do you need a key consumable or component that can ensure absolute accuracy of experimental data and highly reliable production process?

Answer: Choosing our customized quartz sample tube means that you have chosen almost zero metal ion precipitation, excellent optical transmittance (especially in the ultraviolet band), and outstanding thermal shock resistance, fundamentally ensuring the repeatability of your process and product yield.

High purity quartz sample tube is a transparent or semi transparent tubular product made from natural crystal or high-purity silica sand through high-temperature melting, precision molding, and post-treatment. Its core value lies in:

-Ultra high purity: SiO ₂ content ≥ 99.99% (4N grade), with extremely low content of key impurity elements (such as Al, Fe, Na, K, etc.), usually less than 10ppm.

-Excellent temperature resistance: The softening point is about 1730 ℃, and the long-term use temperature can reach 1100-1200 ℃, with higher short-term tolerance.

-Excellent chemical stability: except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acids and has strong corrosion resistance.

-Low thermal expansion coefficient: about 5.5 × 10 ⁻⁷/℃, excellent thermal stability, superior thermal shock resistance.

-Excellent optical performance: It has good transmittance in both ultraviolet and infrared bands, especially suitable for spectral analysis and other scenarios.

Core application areas

-Semiconductor and Photovoltaic Industry: Used for chip carrier tubes in diffusion and oxidation processes, as well as thermal field components in polycrystalline silicon ingot furnaces.

-Fiber optic communication: as a carrier tube (support tube) for depositing fiber optic preforms.

-High end analytical instruments: sample cells, atomizers, or combustion tubes used as atomic absorption spectroscopy (AAS), inductively coupled plasma (ICP), and other instruments.

-Laboratory research: Sample processing under high-temperature reaction tubes, tube furnace reactors, vacuum or inert atmosphere protection.

-Special lighting: the outer cover of halogen lamps and ultraviolet sterilization lamps.

Our product advantage: Why is the performance more outstanding?

-Raw material precision control: Strictly screened high-purity quartz sand is used to ensure low impurities from the source.

-Advanced melting process: using vacuum or inert atmosphere electric melting method to minimize the introduction of bubbles and impurities.

-Precision machining technology: capable of high-precision cutting, chamfering, polishing, flame sealing, bending and forming, with strict control of dimensional tolerances.

-Strict quality inspection: Each batch of products undergoes multiple tests, including dimensional accuracy, wall thickness uniformity, bubble density, transmittance, and impurity content.

Customized Services: Meeting the Individual Needs of Global Customers

We are well aware that standard products cannot meet all innovation needs. We provide comprehensive customized services:

-Flexible customization of size: The outer diameter range is from 2mm to 300mm, and the longest length can reach 3000mm. The wall thickness can be adjusted according to pressure and temperature resistance requirements.

-Customization of shape and structure: It can produce complex structures such as straight pipes, irregular pipes, open/closed ends, expanded ends, and necking.

-Surface treatment customization: providing different surface states such as transparent, frosted, frosted, and coated (such as anti-static coating).

-High purity grades are available: providing different purity specifications such as standard grade (99.99%) and ultra-high purity grade (above 99.998%).

Customer Application Case (Anonymous)

-Case A (a top research institution in Europe): Customized thick walled quartz tubes for high-temperature and high-pressure hydrothermal reactions, requiring ultra smooth inner walls and no defects. We achieved the requirements through a special polishing process, which greatly improved the reproducibility of the experimental results.

-Case B (a well-known semiconductor equipment manufacturer in Asia): We require a large quantity and high consistency of quartz diffusion tubes, with strict requirements for radial jump and straightness. We have optimized the annealing process to ensure that the thermal deformation of each tube is extremely small, and the yield rate exceeds customer expectations.

-Case C (a North American analytical instrument manufacturer): Developed a special structure quartz atomization chamber for its new ICP-OES instrument. We collaborated on the design and successfully made a one-time sample, helping its new instrument to be quickly launched.

Embark on your journey of precision manufacturing

Whether you are in the research and development stage and need sample testing, or have entered mass production and require stable and reliable long-term supply, we can provide you with the most professional high-purity quartz sample tube solution.

Contact us immediately for free samples or technical consultation. Submit your specific requirements (drawings, application environment, performance requirements), and our engineering team will provide you with customized solutions and quotations within 24 hours. Let us use "purity" and "precision" to jointly achieve your next cutting-edge product and breakthrough discovery.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.

High purity quartz sample tube

Q: Are you looking for a material that can withstand extreme high temperatures (up to 1200 ° C or above), has extremely stable chemical properties, and almost does not contaminate sensitive samples or reactions?

Answer: Our high-purity quartz sample tube is designed for this purpose. It solves the core problems in the fields of semiconductors, photovoltaics, fiber preform, high-end laboratory analysis, etc. - the pollution risk caused by insufficient material purity, equipment failure caused by poor thermal stability, and compatibility issues caused by non customized sizes.

Q: Do you need a key consumable or component that can ensure absolute accuracy of experimental data and highly reliable production process?

Answer: Choosing our customized quartz sample tube means that you have chosen almost zero metal ion precipitation, excellent optical transmittance (especially in the ultraviolet band), and outstanding thermal shock resistance, fundamentally ensuring the repeatability of your process and product yield.

High purity quartz sample tube is a transparent or semi transparent tubular product made from natural crystal or high-purity silica sand through high-temperature melting, precision molding, and post-treatment. Its core value lies in:

-Ultra high purity: SiO ₂ content ≥ 99.99% (4N grade), with extremely low content of key impurity elements (such as Al, Fe, Na, K, etc.), usually less than 10ppm.

-Excellent temperature resistance: The softening point is about 1730 ℃, and the long-term use temperature can reach 1100-1200 ℃, with higher short-term tolerance.

-Excellent chemical stability: except for hydrofluoric acid and hot phosphoric acid, it hardly reacts with other acids and has strong corrosion resistance.

-Low thermal expansion coefficient: about 5.5 × 10 ⁻⁷/℃, excellent thermal stability, superior thermal shock resistance.

-Excellent optical performance: It has good transmittance in both ultraviolet and infrared bands, especially suitable for spectral analysis and other scenarios.

Core application areas

-Semiconductor and Photovoltaic Industry: Used for chip carrier tubes in diffusion and oxidation processes, as well as thermal field components in polycrystalline silicon ingot furnaces.

-Fiber optic communication: as a carrier tube (support tube) for depositing fiber optic preforms.

-High end analytical instruments: sample cells, atomizers, or combustion tubes used as atomic absorption spectroscopy (AAS), inductively coupled plasma (ICP), and other instruments.

-Laboratory research: Sample processing under high-temperature reaction tubes, tube furnace reactors, vacuum or inert atmosphere protection.

-Special lighting: the outer cover of halogen lamps and ultraviolet sterilization lamps.

Our product advantage: Why is the performance more outstanding?

-Raw material precision control: Strictly screened high-purity quartz sand is used to ensure low impurities from the source.

-Advanced melting process: using vacuum or inert atmosphere electric melting method to minimize the introduction of bubbles and impurities.

-Precision machining technology: capable of high-precision cutting, chamfering, polishing, flame sealing, bending and forming, with strict control of dimensional tolerances.

-Strict quality inspection: Each batch of products undergoes multiple tests, including dimensional accuracy, wall thickness uniformity, bubble density, transmittance, and impurity content.

Customized Services: Meeting the Individual Needs of Global Customers

We are well aware that standard products cannot meet all innovation needs. We provide comprehensive customized services:

-Flexible customization of size: The outer diameter range is from 2mm to 300mm, and the longest length can reach 3000mm. The wall thickness can be adjusted according to pressure and temperature resistance requirements.

-Customization of shape and structure: It can produce complex structures such as straight pipes, irregular pipes, open/closed ends, expanded ends, and necking.

-Surface treatment customization: providing different surface states such as transparent, frosted, frosted, and coated (such as anti-static coating).

-High purity grades are available: providing different purity specifications such as standard grade (99.99%) and ultra-high purity grade (above 99.998%).

Customer Application Case (Anonymous)

-Case A (a top research institution in Europe): Customized thick walled quartz tubes for high-temperature and high-pressure hydrothermal reactions, requiring ultra smooth inner walls and no defects. We achieved the requirements through a special polishing process, which greatly improved the reproducibility of the experimental results.

-Case B (a well-known semiconductor equipment manufacturer in Asia): We require a large quantity and high consistency of quartz diffusion tubes, with strict requirements for radial jump and straightness. We have optimized the annealing process to ensure that the thermal deformation of each tube is extremely small, and the yield rate exceeds customer expectations.

-Case C (a North American analytical instrument manufacturer): Developed a special structure quartz atomization chamber for its new ICP-OES instrument. We collaborated on the design and successfully made a one-time sample, helping its new instrument to be quickly launched.

Embark on your journey of precision manufacturing

Whether you are in the research and development stage and need sample testing, or have entered mass production and require stable and reliable long-term supply, we can provide you with the most professional high-purity quartz sample tube solution.

Contact us immediately for free samples or technical consultation. Submit your specific requirements (drawings, application environment, performance requirements), and our engineering team will provide you with customized solutions and quotations within 24 hours. Let us use "purity" and "precision" to jointly achieve your next cutting-edge product and breakthrough discovery.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.