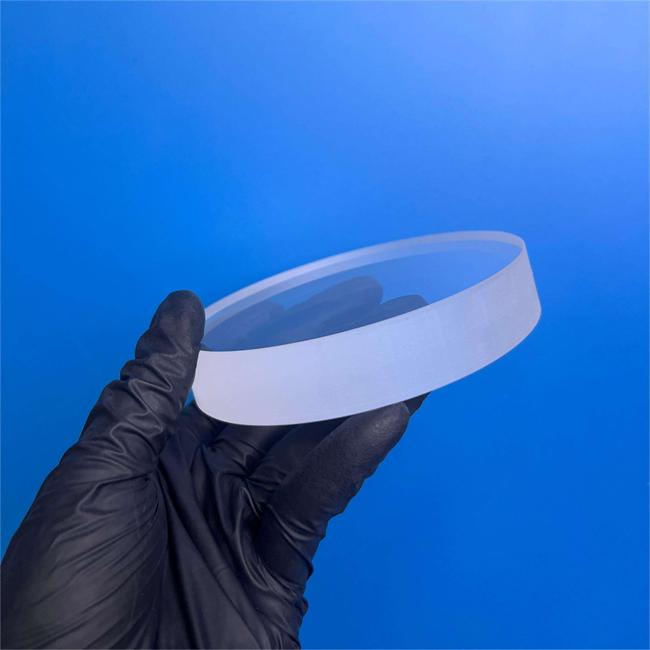

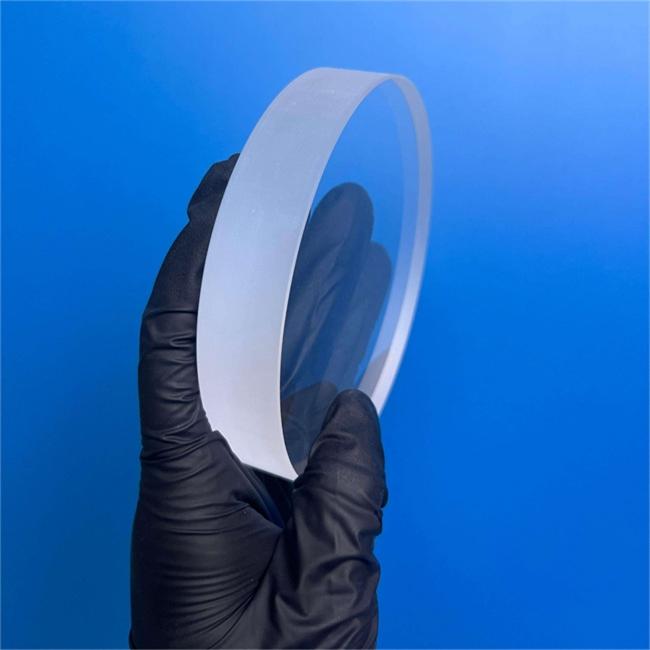

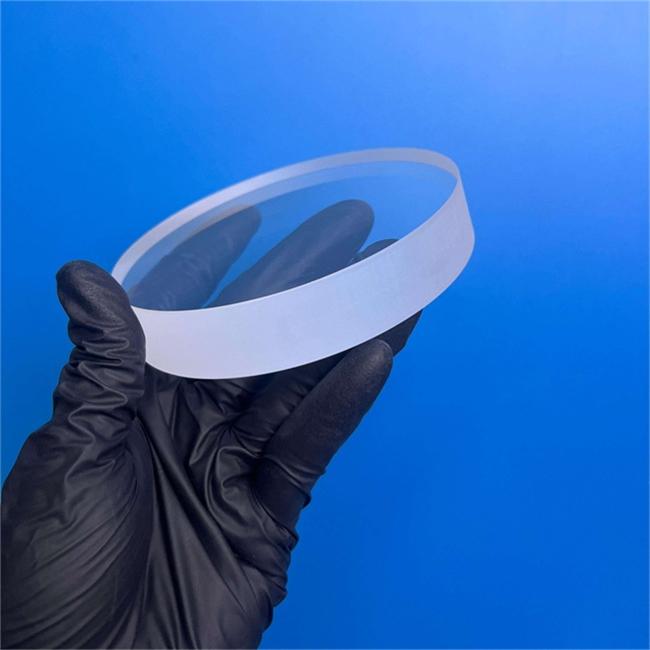

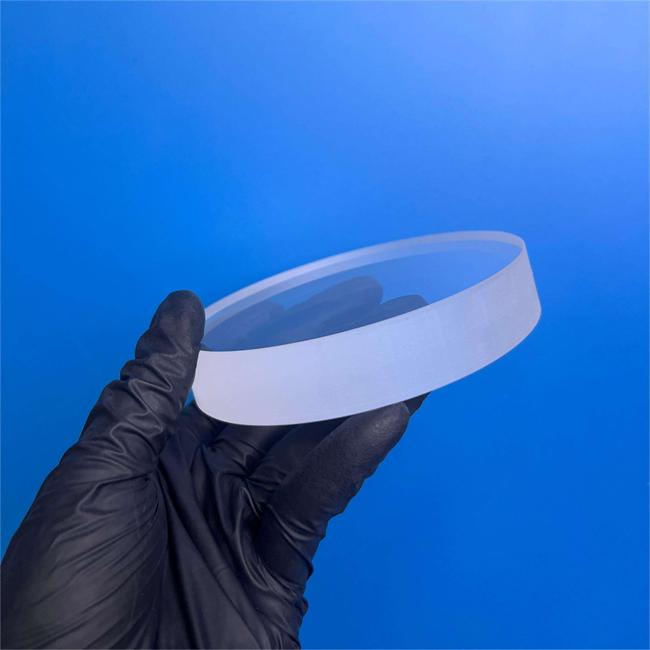

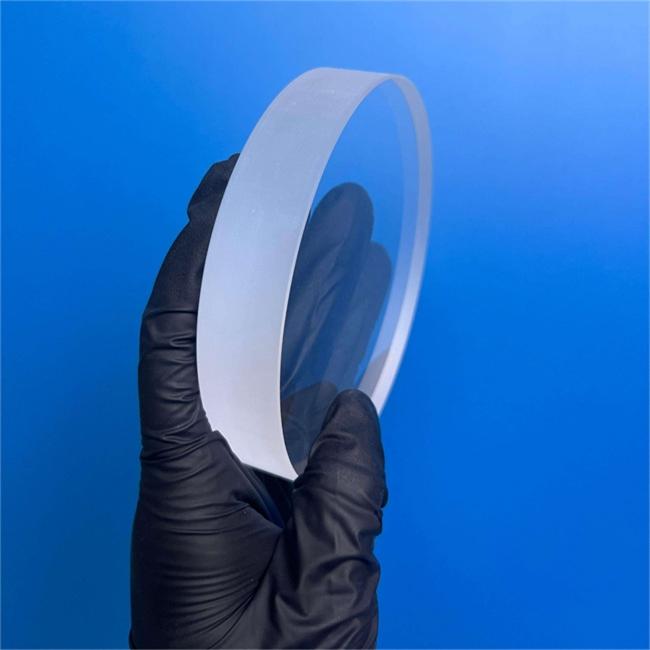

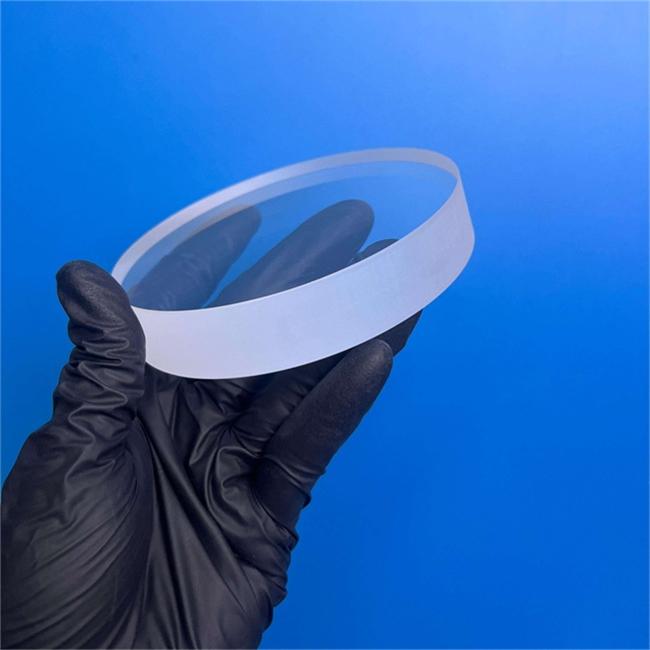

Ultra thick quartz substrate

Your core needs, our solutions

Q: What should be done if traditional materials are prone to deformation or damage in high temperature or corrosive environments?

A: Our ultra thick quartz substrate provides excellent thermal stability and chemical inertness, which can maintain dimensional stability at high temperatures of 1200 ℃ and strong acid and alkali environments, extending the service life of equipment.

Q: Precision instruments require extremely high dimensional accuracy and surface flatness. How can this be achieved?

A: Through advanced grinding and polishing processes, we can provide a surface roughness of Ra ≤ 0.1 μ m, with a thickness tolerance controlled within ± 0.01mm, meeting the precision requirements of semiconductor, optical and other fields.

Q: Can special projects require non-standard sizes and shapes for quick customization?

A: We support full-size customization, with a diameter range from 10mm to 2000mm and a thickness of up to 100mm. We also provide secondary processing services such as drilling, slotting, and irregular cutting.

Product Definition and Characteristics

Ultra thick quartz substrate (thickness ≥ 10mm) is made of high-purity fused silica material (SiO ₂ content ≥ 99.99%) through precision controlled production process, and has the following key characteristics:

-Thermal performance: The coefficient of thermal expansion is extremely low (5.5 × 10 ⁻⁷/℃), and the temperature difference for heat shock resistance can reach 1000 ℃

-Optical performance: High transmittance in the ultraviolet to infrared wavelength range (170nm-2500nm)

-Mechanical properties: compressive strength>1100MPa, hardness Mohs 7

-Chemical stability: resistant to most chemical reagents except hydrofluoric acid and hot phosphoric acid

Main application areas

1. Semiconductor manufacturing

-Wafer carrier plate and diffusion furnace baffle

-Mask substrate in etching process

-Supporting Platform for High Temperature Annealing Process

2. Precision optics

-Window and reflector substrate of high-power laser

-Calibration plate for astronomical telescopes

-Core optical components of spectrometer

3. Laboratory equipment

-High temperature observation window

-Special reaction vessel window

-Precision measuring instrument platform

4. In the field of new energy

-Carrier substrate in the manufacturing process of photovoltaic panels

-Fuel cell testing equipment

Product specifications and customization capabilities

Standard specification range

-Thickness: 10mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 80mm, 100mm

-Size: Circular diameter 50-1500mm, square/rectangular 50 × 50mm-1500 × 2000mm

-Surface treatment: single/double-sided polishing, matte, frosted

customized service

1. Size customization: produce according to demand for any thickness, diameter, or shape

2. Accuracy control: Adjust thickness tolerance and flatness according to application requirements

3. Secondary processing: CNC precision machining, drilling, slotting, chamfering

4. Surface treatment: Coating (anti reflective film, reflective film, ITO conductive film, etc.)

5. Special treatment: High temperature annealing enhancement, UV transmittance optimization

Detailed explanation of core advantages

technical advantage

-Material purity: Adopting a four level purification process to ensure a SiO ₂ content of over 99.99%

-Process control: Vertical pull-down method combined with precision annealing to eliminate internal stress

-Testing system: equipped with laser interferometers, profilometers and other testing equipment, with full process quality control

performance advantage

1. Dimensional stability: When the temperature changes by 1000 ℃, the dimensional change is less than 0.01%

2. Anti deformation ability: Under a load of 100kg, the deformation of a 1m diameter substrate is less than 0.05mm

3. Service life: In the semiconductor manufacturing environment, the service life is extended by 3-5 times compared to ordinary materials

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 15 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)

7. Flexible cooperation mode

Support small batch trial orders, medium - and long-term cooperation, and urgent production for urgent orders, providing OEM/ODM services.

Customer Application Cases

Case 1: European semiconductor equipment manufacturer

Challenge: A wafer carrier disk that can withstand high temperatures of 1200 ℃ and has a monthly thermal cycle deformation of less than 0.005mm is required

Solution: Customized 300mm diameter, 25mm thickness quartz substrate, surface polished to Ra 0.08 μ m

Result: The customer's equipment has been running continuously for 18 months without substrate replacement, resulting in a 2.3% increase in wafer yield rate

Case 2: American Laser Research Institute

Requirement: Window materials with low thermal lens effect in high-power laser systems

Solution: Provide a quartz window with a thickness of 40mm and double-sided anti reflective coating

Effect: Under 10kW continuous laser irradiation, the transmittance remains above 99.5%, and thermal deformation can be ignored

Case 3: Japan Precision Instrument Company

Problem: Rapid atomization of chemical analysis instrument windows in corrosive gases

Solution: Customized chemical enhanced quartz window with a thickness of 15mm

Result: The service life in HCl gas environment has been extended from 3 months to over 3 years

Whether you are looking for standard specification ultra thick quartz substrates or customized projects with special application requirements, our engineering team is happy to provide you with professional technical advice and solutions.

Contact us immediately for personalized quotes and technical solutions, or request samples to test the quality of our products. Please check the specific contact information on the official website, or send your requirements directly to the sales email. We will provide you with detailed technical specifications and business solutions within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.