T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

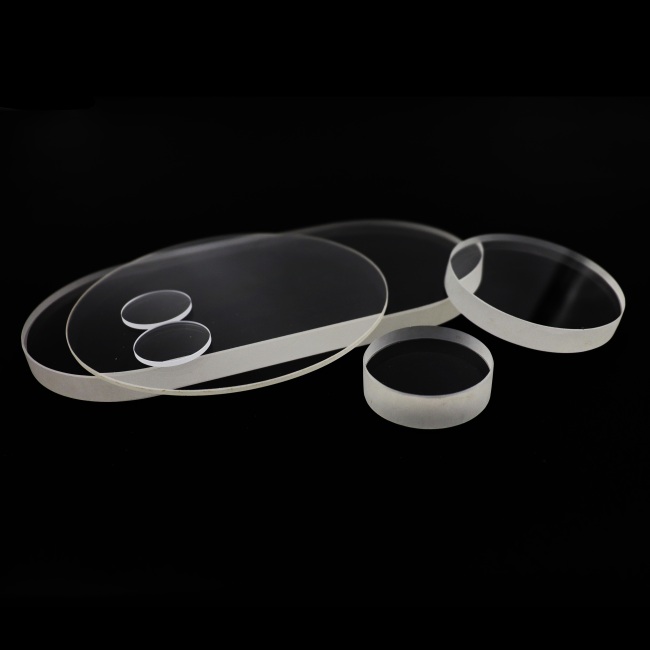

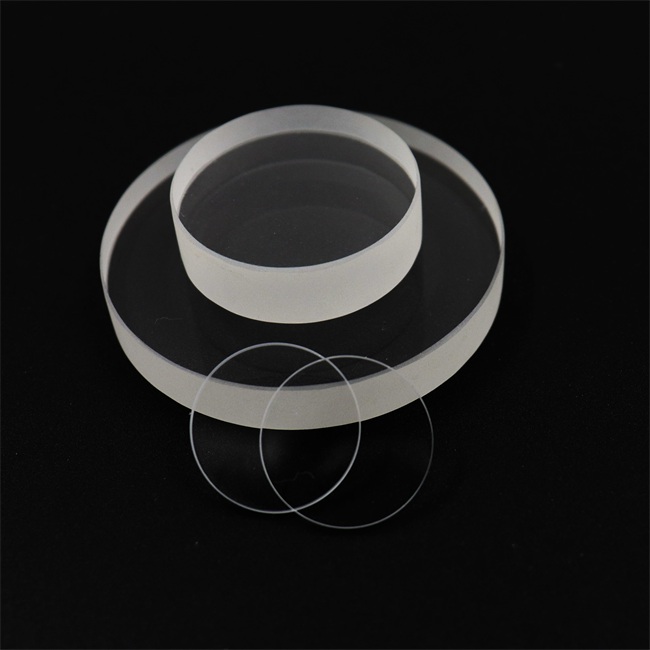

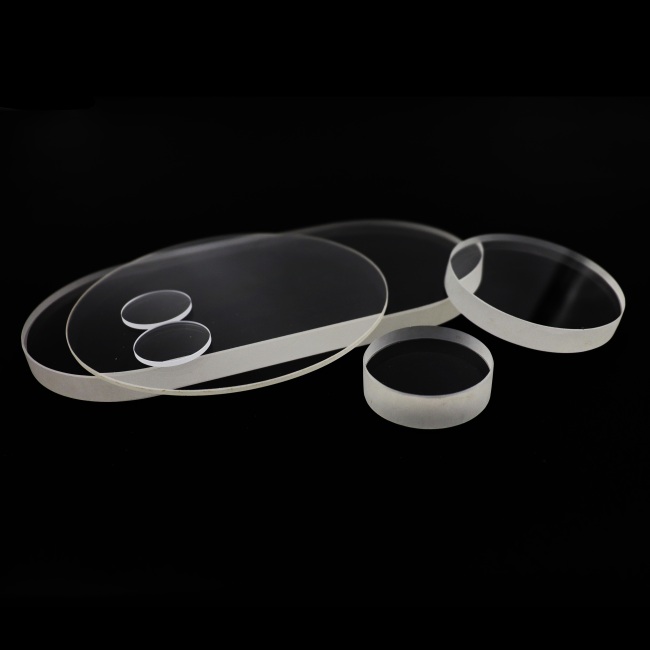

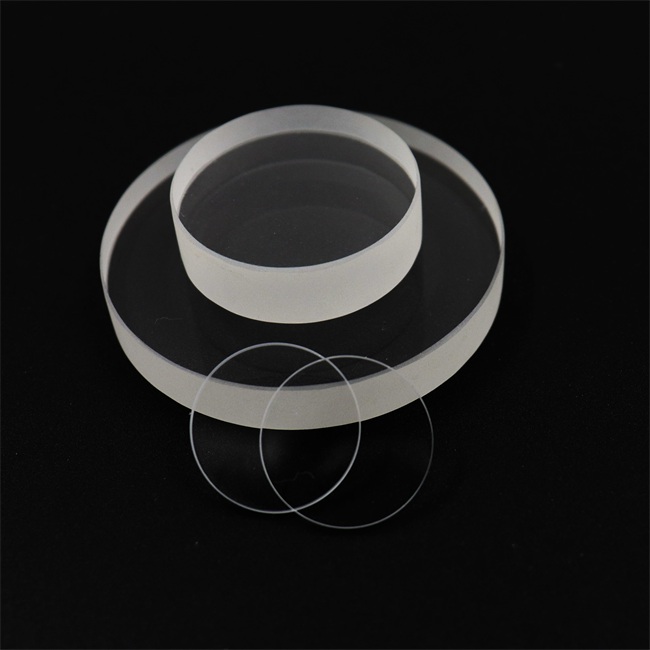

Polishing JGS1 JGS2 quartz glass plate

Polished JGS1 and JGS2 quartz glass plates are high-end optical substrates made from high-purity natural quartz or synthetic quartz through precision cold processing and optical polishing processes.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

Polishing JGS1 JGS2 quartz glass plate

Polished JGS1 and JGS2 quartz glass plates are high-end optical substrates made from high-purity natural quartz or synthetic quartz through precision cold processing and optical polishing processes. They are not ordinary glass, but high-performance materials with a series of unique physical and chemical properties that can meet the needs of extreme environments and high-precision applications.

Core material characteristics:

Extremely high spectral transmission range:

JGS1 (far ultraviolet optical quartz glass): Using synthetic technology, it has extremely high purity and high hydroxyl content. It has extremely high transmittance in the ultraviolet band (especially 185nm-250nm), making it an ideal window and substrate material for deep ultraviolet applications.

JGS2 (UV Optical Quartz Glass): Made by melting high-purity natural crystals, it has good transmittance in the UV and visible light bands (260nm-350nm) and is a cost-effective UV optical material.

Excellent thermal stability: With an extremely low coefficient of thermal expansion (about 5.5 × 10 ⁻⁷/℃), it can withstand drastic temperature changes without breaking or deforming, and its heat shock resistance far exceeds that of ordinary glass.

Excellent mechanical properties and chemical stability: high surface hardness, abrasion resistance, and resistance to most chemical substances such as water and acid (except hydrofluoric acid and hot phosphoric acid), ensuring long-term stability in harsh environments.

High laser damage threshold: Due to its high purity and uniform internal structure, it can withstand high-power laser irradiation and is a key component in laser optical systems.

Our processing capability:

We provide precision polished plates with different thicknesses ranging from micrometer to millimeter. The surface smoothness can reach λ/10 @ 632.8nm, and key indicators such as parallelism and flatness can be strictly controlled according to customer needs to ensure that each product achieves optical grade high precision.

What problems can we solve?

In many high-end applications, ordinary glass or low-quality optical materials can become bottlenecks in system performance. Our polished JGS1/JGS2 quartz glass panels are designed to address these core pain points:

1. Solve the problem of "UV signal attenuation":

Pain point: Ordinary glass strongly absorbs ultraviolet radiation, resulting in weak signals and insufficient sensitivity of ultraviolet detection equipment.

Solution: The high transmittance of JGS1/JGS2 quartz glass in the ultraviolet band ensures the maximum utilization of ultraviolet light, significantly improving the efficiency of spectrometers, ultraviolet detectors, and sterilization equipment.

2. Solve the problem of "thermal deformation and rupture":

Pain point: In high-power lasers, high-temperature reaction chambers, or rapidly changing temperature environments, ordinary optical components may undergo deformation, focal drift, or even explosion due to thermal expansion and contraction.

Solution: The extremely low thermal expansion coefficient and excellent heat resistance of quartz glass ensure the dimensional stability and reliability of optical systems in high-temperature environments, extending equipment life.

3. Solve the problem of "laser system damage":

Pain point: Impurities, bubbles, or microscopic defects inside the material can become damage points under high-energy laser irradiation, leading to component ablation.

Solution: We use high-purity raw materials and precision manufacturing processes to ensure that the product has no defects inside, has a high laser damage threshold, and guarantees the safe and stable operation of high-power lasers.

4. Addressing the issue of poor environmental tolerance:

Pain point: In humid, acidic, or frequently cleaned industrial environments, the surface of optical components is prone to corrosion or wear, leading to a decrease in performance.

Solution: The excellent chemical stability and high hardness of quartz glass enable it to withstand harsh environments, be easy to clean and maintain, and maintain long-lasting clarity and performance.

Main application areas

With its excellent performance, polished JGS1/JGS2 quartz glass panels are widely used in the following high-tech fields:

UV optical system:

Window and prism of UV spectrometer and spectrophotometer

Protective observation window of ultraviolet sterilization lamp (UVC)

Mask substrate for semiconductor lithography equipment

Laser technology:

Output window, reflector substrate, and beam expander of high-power laser

Protective lenses for laser processing equipment (cutting, welding, marking)

Semiconductors and Integrated Circuits:

Carrier disks and baffles during wafer processing

Observation windows for lithography machines, CVD and PVD equipment

Analytical instruments and scientific research:

Optical windows and detector protective covers for aerospace applications

Synchrotron radiation beamlines and components of astronomical observation equipment

Optical platforms and sample substrates for various precision experimental devices

Chemical and Medical:

Corrosion resistant observation window for high-temperature reaction kettle

Flow cell and detection window of medical analytical instruments (such as blood analyzers)

Customized service

We are well aware that standard products often cannot meet the unique needs of all projects. Therefore, we provide comprehensive and flexible customized services to tailor the most suitable solution for you.

Customization of size and shape:

We can provide circular, square, rectangular, and various irregular cutting options.

The size range ranges from a few millimeters to several hundred millimeters, meeting different needs from miniature sensors to large devices.

Thickness and tolerance control:

Specific thickness can be customized according to your structural strength and optical path requirements.

Strictly control the thickness tolerance, parallelism, and flatness to ensure the imaging quality of the optical system.

Surface precision customization:

Provide different levels of surface smoothness (such as 60-40, 20-10, 10-5 scratch pitting) and surface accuracy (λ/4, λ/10, λ/20).

Double sided polishing or single-sided polishing can be performed.

Coating service:

We provide various optical coatings such as anti reflective film (AR film), reflective film, and spectral film, covering different wavelengths from ultraviolet to infrared, to maximize light utilization efficiency and reduce system stray light.

Special treatment:

It can perform subsequent precision machining such as punching, chamfering, and edge grinding.

Contact us immediately for exclusive pricing and technical consultation!

Let our polished JGS1/JGS2 quartz glass plates become the most reliable cornerstone in your high-end optical systems.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.

Polishing JGS1 JGS2 quartz glass plate

Polished JGS1 and JGS2 quartz glass plates are high-end optical substrates made from high-purity natural quartz or synthetic quartz through precision cold processing and optical polishing processes. They are not ordinary glass, but high-performance materials with a series of unique physical and chemical properties that can meet the needs of extreme environments and high-precision applications.

Core material characteristics:

Extremely high spectral transmission range:

JGS1 (far ultraviolet optical quartz glass): Using synthetic technology, it has extremely high purity and high hydroxyl content. It has extremely high transmittance in the ultraviolet band (especially 185nm-250nm), making it an ideal window and substrate material for deep ultraviolet applications.

JGS2 (UV Optical Quartz Glass): Made by melting high-purity natural crystals, it has good transmittance in the UV and visible light bands (260nm-350nm) and is a cost-effective UV optical material.

Excellent thermal stability: With an extremely low coefficient of thermal expansion (about 5.5 × 10 ⁻⁷/℃), it can withstand drastic temperature changes without breaking or deforming, and its heat shock resistance far exceeds that of ordinary glass.

Excellent mechanical properties and chemical stability: high surface hardness, abrasion resistance, and resistance to most chemical substances such as water and acid (except hydrofluoric acid and hot phosphoric acid), ensuring long-term stability in harsh environments.

High laser damage threshold: Due to its high purity and uniform internal structure, it can withstand high-power laser irradiation and is a key component in laser optical systems.

Our processing capability:

We provide precision polished plates with different thicknesses ranging from micrometer to millimeter. The surface smoothness can reach λ/10 @ 632.8nm, and key indicators such as parallelism and flatness can be strictly controlled according to customer needs to ensure that each product achieves optical grade high precision.

What problems can we solve?

In many high-end applications, ordinary glass or low-quality optical materials can become bottlenecks in system performance. Our polished JGS1/JGS2 quartz glass panels are designed to address these core pain points:

1. Solve the problem of "UV signal attenuation":

Pain point: Ordinary glass strongly absorbs ultraviolet radiation, resulting in weak signals and insufficient sensitivity of ultraviolet detection equipment.

Solution: The high transmittance of JGS1/JGS2 quartz glass in the ultraviolet band ensures the maximum utilization of ultraviolet light, significantly improving the efficiency of spectrometers, ultraviolet detectors, and sterilization equipment.

2. Solve the problem of "thermal deformation and rupture":

Pain point: In high-power lasers, high-temperature reaction chambers, or rapidly changing temperature environments, ordinary optical components may undergo deformation, focal drift, or even explosion due to thermal expansion and contraction.

Solution: The extremely low thermal expansion coefficient and excellent heat resistance of quartz glass ensure the dimensional stability and reliability of optical systems in high-temperature environments, extending equipment life.

3. Solve the problem of "laser system damage":

Pain point: Impurities, bubbles, or microscopic defects inside the material can become damage points under high-energy laser irradiation, leading to component ablation.

Solution: We use high-purity raw materials and precision manufacturing processes to ensure that the product has no defects inside, has a high laser damage threshold, and guarantees the safe and stable operation of high-power lasers.

4. Addressing the issue of poor environmental tolerance:

Pain point: In humid, acidic, or frequently cleaned industrial environments, the surface of optical components is prone to corrosion or wear, leading to a decrease in performance.

Solution: The excellent chemical stability and high hardness of quartz glass enable it to withstand harsh environments, be easy to clean and maintain, and maintain long-lasting clarity and performance.

Main application areas

With its excellent performance, polished JGS1/JGS2 quartz glass panels are widely used in the following high-tech fields:

UV optical system:

Window and prism of UV spectrometer and spectrophotometer

Protective observation window of ultraviolet sterilization lamp (UVC)

Mask substrate for semiconductor lithography equipment

Laser technology:

Output window, reflector substrate, and beam expander of high-power laser

Protective lenses for laser processing equipment (cutting, welding, marking)

Semiconductors and Integrated Circuits:

Carrier disks and baffles during wafer processing

Observation windows for lithography machines, CVD and PVD equipment

Analytical instruments and scientific research:

Optical windows and detector protective covers for aerospace applications

Synchrotron radiation beamlines and components of astronomical observation equipment

Optical platforms and sample substrates for various precision experimental devices

Chemical and Medical:

Corrosion resistant observation window for high-temperature reaction kettle

Flow cell and detection window of medical analytical instruments (such as blood analyzers)

Customized service

We are well aware that standard products often cannot meet the unique needs of all projects. Therefore, we provide comprehensive and flexible customized services to tailor the most suitable solution for you.

Customization of size and shape:

We can provide circular, square, rectangular, and various irregular cutting options.

The size range ranges from a few millimeters to several hundred millimeters, meeting different needs from miniature sensors to large devices.

Thickness and tolerance control:

Specific thickness can be customized according to your structural strength and optical path requirements.

Strictly control the thickness tolerance, parallelism, and flatness to ensure the imaging quality of the optical system.

Surface precision customization:

Provide different levels of surface smoothness (such as 60-40, 20-10, 10-5 scratch pitting) and surface accuracy (λ/4, λ/10, λ/20).

Double sided polishing or single-sided polishing can be performed.

Coating service:

We provide various optical coatings such as anti reflective film (AR film), reflective film, and spectral film, covering different wavelengths from ultraviolet to infrared, to maximize light utilization efficiency and reduce system stray light.

Special treatment:

It can perform subsequent precision machining such as punching, chamfering, and edge grinding.

Contact us immediately for exclusive pricing and technical consultation!

Let our polished JGS1/JGS2 quartz glass plates become the most reliable cornerstone in your high-end optical systems.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of fused quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from fused quartz lumps to fused quartz sand and then fused quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult fused quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of fused quartz plates, tubes and high size precision fused quartz items.