T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

5-100mm thick quartz plate

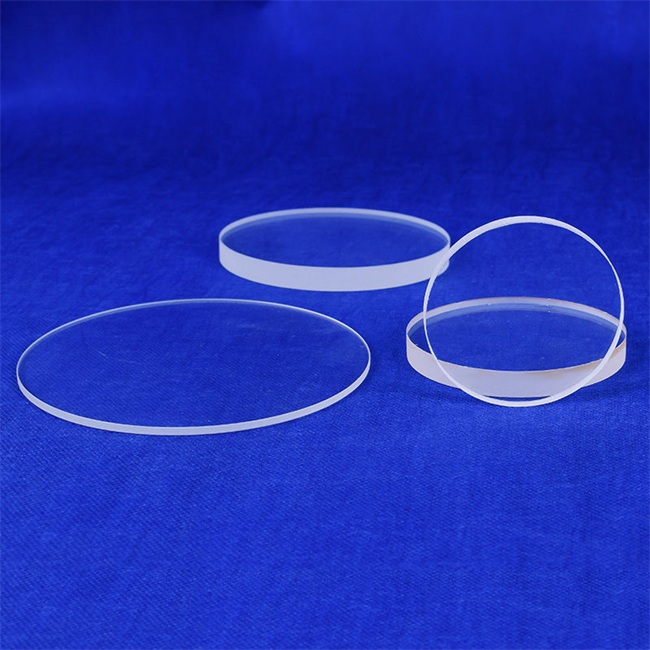

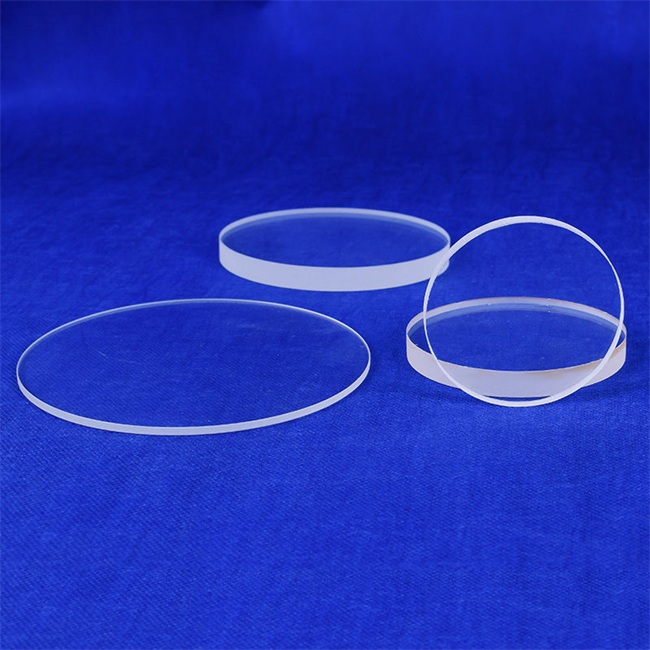

5-100mm thick quartz plate, made of high-purity quartz as raw material, melted at high temperature.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

5-100mm thick quartz plate, made of high-purity quartz as raw material, melted at high temperature. Wide thickness coverage, high temperature resistance, corrosion resistance, good transparency, and stable chemical properties. Suitable for semiconductor, photovoltaic, laboratory and other fields, meeting the needs of high temperature and precision scenarios.

As a professional manufacturer specializing in the production and foreign trade of quartz products, we are committed to providing high-quality and high-precision customized quartz plate products to global customers. Quartz plate, as a key industrial material, plays an indispensable role in many high-tech and traditional industries. This article will provide a detailed introduction to the characteristics, applications, advantages, and why you chose us for 5-100mm thickness quartz plates. At the same time, we will share customer cases to provide you with comprehensive product references.

Product Overview: 5-100mm thick quartz plate

Quartz plate is a sheet made of high-purity silicon dioxide (SiO ₂) through melting, cooling, and precision processing. The thickness range of the quartz plates we provide is from 5mm to 100mm, and the width and length can be customized according to customer needs. The maximum size can reach 2000mm x 3000mm. The product uses carefully selected raw materials with a purity of over 99.99%, ensuring low bubbles, high transparency, and excellent physical and chemical stability.

Key parameters:

-Thickness range: 5mm, 10mm, 20mm, 30mm, 50mm, 80mm, 100mm (supports customization of intermediate thickness)

-Purity: ≥ 99.99%

-Transmittance: Visible light band ≥ 93% (reference value for 2mm thickness)

-Temperature resistance: Long term use temperature can reach 1100 ℃, short-term tolerance 1450 ℃

-Thermal expansion coefficient: 5.5 × 10 ⁻⁷/℃, almost zero expansion

Product application areas

Quartz plates are widely used in the following industries due to their high temperature resistance, corrosion resistance, high transparency, and electrical insulation properties:

1. Semiconductor and Electronics Industry

Used for wafer processing, photolithography onplate, CVD reaction chamber windows, etching equipment components, etc. The high purity and chemical resistance of quartz plates can prevent contamination and ensure process stability.

2. Optics and Optoelectronics

As a laser window, optical lens substrate, ultraviolet transmission lens, etc. Its high transparency and low thermal expansion coefficient make it perform excellently in precision optical systems.

3. Chemical and laboratory equipment

Used for reactor windows, pipeline lining, acid resistant containers, etc. Quartz plates have strong resistance to most acids (except hydrofluoric acid and hot phosphoric acid).

4. New energy and photovoltaic industry

Applied to solar plate cover layers, photovoltaic reaction equipment observation windows, etc. Weather resistance and high transparency help improve energy conversion efficiency.

5. High temperature industrial furnaces and heat treatment

As an observation window, insulation plate, or load-bearing plate, it can work stably for a long time in high-temperature environments such as glass furnaces and ceramic sintering.

Product advantages and problem-solving abilities

1. Excellent high temperature resistance and thermal stability

The thermal expansion coefficient of quartz plate is extremely low, and it is not easy to crack or deform under severe temperature changes, which solves the common problem of material failure in high-temperature environments.

2. High purity and chemical inertness

The raw material has high purity and does not precipitate impurities, making it suitable for sensitive processes. The corrosion resistance property extends the service life of the equipment in strong acid and alkali environments.

3. Excellent optical performance

High transmittance (especially in the ultraviolet band) and low fluorescence characteristics meet the stringent requirements for material transparency and signal purity in optical and optoelectronic applications.

4. Customized processing capability

Supporting secondary processing such as drilling, cutting, grinding, polishing, and coating, we can produce irregular parts according to customer drawings to solve the problem of non-standard equipment matching.

5. Mechanical strength and durability

Compared to ordinary glass, quartz plates have stronger hardness and scratch resistance, and can still maintain surface integrity and functionality in harsh industrial environments.

Why choose us?

1. Professional production experience

With over 20 years of history in quartz product manufacturing, our products are exported to more than 50 countries and regions including Europe, America, Japan, South Korea, and the Middle East, and we are well versed in global industrial standards and demands.

2 complete customized services

Provide a one-stop solution from technical consultation, drawing optimization to production delivery, quickly respond to sample requirements, and support small batch trial orders to large-scale orders.

3. Stable supply capacity

We have our own modern factory and advanced melting and CNC processing equipment, with a monthly production capacity of 5000 square meters, ensuring timely delivery and supporting long-term cooperation.

4. Cost advantage

Through process optimization and large-scale production, we provide competitive prices while ensuring quality, helping customers reduce procurement costs.

Customer Case (Anonymous)

1. A semiconductor equipment manufacturer in Germany

Requirement: High purity, low bubble 80mm thick quartz carrier plate for the new generation of lithography machines.

Solution: We provide customized quartz plates with dimensions of 1500mm × 2000mm × 80mm, which have undergone precision grinding and polishing to achieve a surface flatness of ≤ 0.01mm.

Result: The product has passed strict customer testing and has been in stable supply for 3 years, with a yield rate of 99.8%.

2. A laser technology company in the United States

Requirement: 5mm and 30mm thick quartz window mirrors with a UV transmittance of ≥ 90% and coated with anti reflective film.

Solution: Using high-purity synthetic quartz raw materials, double-sided polishing and coating, the transmittance is increased to 98%.

Result: The customer's laser output efficiency has increased by 12%, and a long-term exclusive supply agreement has been established.

3. A chemical company in Japan

Requirement: 50mm thick quartz lining plate resistant to hydrofluoric acid corrosion, used for special reaction vessels.

Solution: Select low alkali quartz material and perform special surface treatment to enhance acid corrosion resistance.

Result: The product's service life has been extended by 2 times compared to the original supplier, and the annual maintenance cost has been reduced by 40%.

5-100mm thick quartz plate is a key material for upgrading high-tech and traditional industries. We have become a reliable partner for many international enterprises with our professional production technology, strict quality control, and global service experience. Whether you need standard specifications or special customization, we can provide solutions that meet your needs.

What problems or challenges have you encountered during the use of your product? Welcome to leave a message and communicate with us. Our technical team will provide you with professional advice and work together to optimize your application solution.

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.

5-100mm thick quartz plate, made of high-purity quartz as raw material, melted at high temperature. Wide thickness coverage, high temperature resistance, corrosion resistance, good transparency, and stable chemical properties. Suitable for semiconductor, photovoltaic, laboratory and other fields, meeting the needs of high temperature and precision scenarios.

As a professional manufacturer specializing in the production and foreign trade of quartz products, we are committed to providing high-quality and high-precision customized quartz plate products to global customers. Quartz plate, as a key industrial material, plays an indispensable role in many high-tech and traditional industries. This article will provide a detailed introduction to the characteristics, applications, advantages, and why you chose us for 5-100mm thickness quartz plates. At the same time, we will share customer cases to provide you with comprehensive product references.

Product Overview: 5-100mm thick quartz plate

Quartz plate is a sheet made of high-purity silicon dioxide (SiO ₂) through melting, cooling, and precision processing. The thickness range of the quartz plates we provide is from 5mm to 100mm, and the width and length can be customized according to customer needs. The maximum size can reach 2000mm x 3000mm. The product uses carefully selected raw materials with a purity of over 99.99%, ensuring low bubbles, high transparency, and excellent physical and chemical stability.

Key parameters:

-Thickness range: 5mm, 10mm, 20mm, 30mm, 50mm, 80mm, 100mm (supports customization of intermediate thickness)

-Purity: ≥ 99.99%

-Transmittance: Visible light band ≥ 93% (reference value for 2mm thickness)

-Temperature resistance: Long term use temperature can reach 1100 ℃, short-term tolerance 1450 ℃

-Thermal expansion coefficient: 5.5 × 10 ⁻⁷/℃, almost zero expansion

Product application areas

Quartz plates are widely used in the following industries due to their high temperature resistance, corrosion resistance, high transparency, and electrical insulation properties:

1. Semiconductor and Electronics Industry

Used for wafer processing, photolithography onplate, CVD reaction chamber windows, etching equipment components, etc. The high purity and chemical resistance of quartz plates can prevent contamination and ensure process stability.

2. Optics and Optoelectronics

As a laser window, optical lens substrate, ultraviolet transmission lens, etc. Its high transparency and low thermal expansion coefficient make it perform excellently in precision optical systems.

3. Chemical and laboratory equipment

Used for reactor windows, pipeline lining, acid resistant containers, etc. Quartz plates have strong resistance to most acids (except hydrofluoric acid and hot phosphoric acid).

4. New energy and photovoltaic industry

Applied to solar plate cover layers, photovoltaic reaction equipment observation windows, etc. Weather resistance and high transparency help improve energy conversion efficiency.

5. High temperature industrial furnaces and heat treatment

As an observation window, insulation plate, or load-bearing plate, it can work stably for a long time in high-temperature environments such as glass furnaces and ceramic sintering.

Product advantages and problem-solving abilities

1. Excellent high temperature resistance and thermal stability

The thermal expansion coefficient of quartz plate is extremely low, and it is not easy to crack or deform under severe temperature changes, which solves the common problem of material failure in high-temperature environments.

2. High purity and chemical inertness

The raw material has high purity and does not precipitate impurities, making it suitable for sensitive processes. The corrosion resistance property extends the service life of the equipment in strong acid and alkali environments.

3. Excellent optical performance

High transmittance (especially in the ultraviolet band) and low fluorescence characteristics meet the stringent requirements for material transparency and signal purity in optical and optoelectronic applications.

4. Customized processing capability

Supporting secondary processing such as drilling, cutting, grinding, polishing, and coating, we can produce irregular parts according to customer drawings to solve the problem of non-standard equipment matching.

5. Mechanical strength and durability

Compared to ordinary glass, quartz plates have stronger hardness and scratch resistance, and can still maintain surface integrity and functionality in harsh industrial environments.

Why choose us?

1. Professional production experience

With over 20 years of history in quartz product manufacturing, our products are exported to more than 50 countries and regions including Europe, America, Japan, South Korea, and the Middle East, and we are well versed in global industrial standards and demands.

2 complete customized services

Provide a one-stop solution from technical consultation, drawing optimization to production delivery, quickly respond to sample requirements, and support small batch trial orders to large-scale orders.

3. Stable supply capacity

We have our own modern factory and advanced melting and CNC processing equipment, with a monthly production capacity of 5000 square meters, ensuring timely delivery and supporting long-term cooperation.

4. Cost advantage

Through process optimization and large-scale production, we provide competitive prices while ensuring quality, helping customers reduce procurement costs.

Customer Case (Anonymous)

1. A semiconductor equipment manufacturer in Germany

Requirement: High purity, low bubble 80mm thick quartz carrier plate for the new generation of lithography machines.

Solution: We provide customized quartz plates with dimensions of 1500mm × 2000mm × 80mm, which have undergone precision grinding and polishing to achieve a surface flatness of ≤ 0.01mm.

Result: The product has passed strict customer testing and has been in stable supply for 3 years, with a yield rate of 99.8%.

2. A laser technology company in the United States

Requirement: 5mm and 30mm thick quartz window mirrors with a UV transmittance of ≥ 90% and coated with anti reflective film.

Solution: Using high-purity synthetic quartz raw materials, double-sided polishing and coating, the transmittance is increased to 98%.

Result: The customer's laser output efficiency has increased by 12%, and a long-term exclusive supply agreement has been established.

3. A chemical company in Japan

Requirement: 50mm thick quartz lining plate resistant to hydrofluoric acid corrosion, used for special reaction vessels.

Solution: Select low alkali quartz material and perform special surface treatment to enhance acid corrosion resistance.

Result: The product's service life has been extended by 2 times compared to the original supplier, and the annual maintenance cost has been reduced by 40%.

5-100mm thick quartz plate is a key material for upgrading high-tech and traditional industries. We have become a reliable partner for many international enterprises with our professional production technology, strict quality control, and global service experience. Whether you need standard specifications or special customization, we can provide solutions that meet your needs.

What problems or challenges have you encountered during the use of your product? Welcome to leave a message and communicate with us. Our technical team will provide you with professional advice and work together to optimize your application solution.

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on.