T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

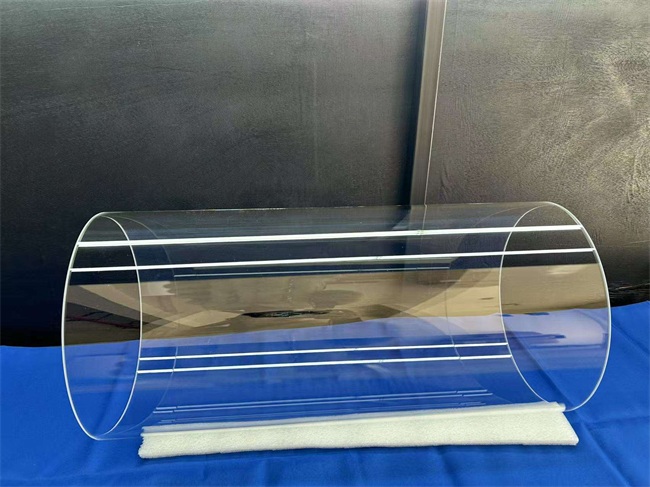

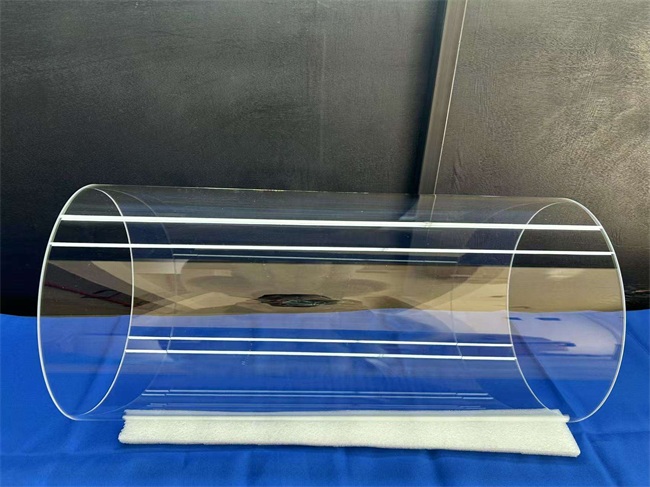

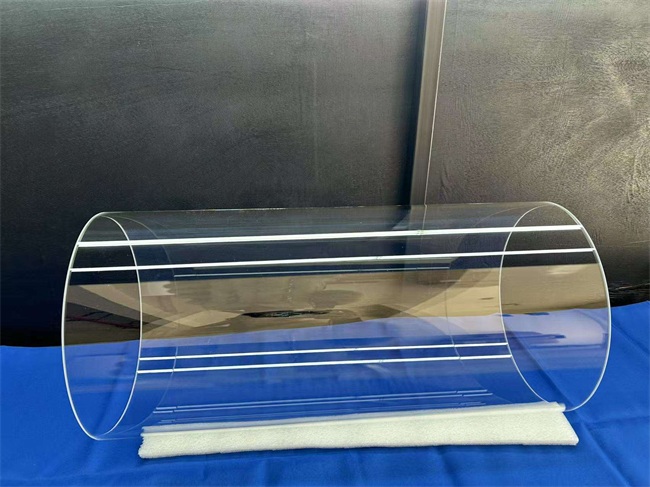

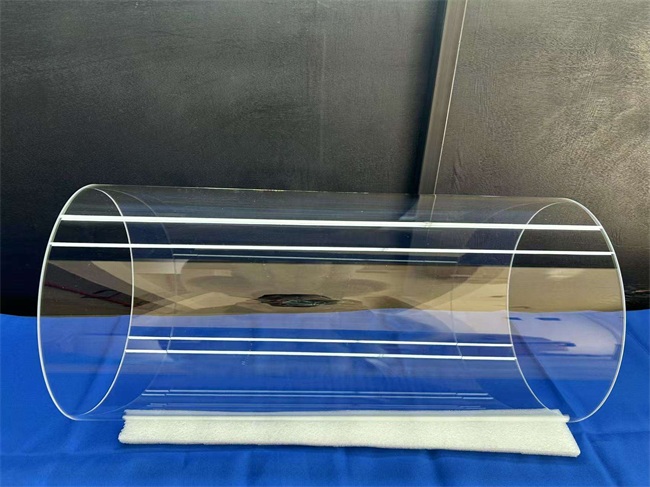

large diameter circular quartz tube

large diameter round quartz tube is a special industrial product made of high-purity fused silica, which is suitable for professional fields with strict requirements on diameter, thermal stability and chemical purity.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

large diameter round quartz tube is a special industrial product made of high-purity fused silica, which is suitable for professional fields with strict requirements on diameter, thermal stability and chemical purity. The product adopts continuous melting process to ensure quality consistency in the full size range from 5mm to 600mm, with wall thickness uniformity controlled within ± 0.5mm and straightness deviation not exceeding 1mm/m.

Core technical parameters

-Diameter range: (supports non-standard customization)

-Purity grade: SiO ₂ content ≥ 99.95% -99.99%

-Thermal expansion coefficient: 5.5 × 10 ⁻⁷/℃ (0-1000 ℃)

-Thermal stability: maximum continuous use temperature of 1150 ℃, short-term temperature resistance of 1300 ℃

-Transmittance performance: Excellent transmittance in the ultraviolet to infrared band (special coating optional)

Key application areas

semiconductor manufacturing

The large-diameter quartz tube (300-600mm) serves as the core component of the diffusion furnace and LPCVD reaction chamber, providing a pollution-free and clean environment for silicon wafer processing. After a European semiconductor equipment manufacturer adopted our 450mm quartz tube, the cleaning cycle of the reaction chamber was extended from the original 4 weeks to 8 weeks, and the particle contamination rate was reduced by 62%.

photovoltaic industry

In solar cell manufacturing, quartz tubes with a diameter of 200-400mm are used for PECVD coating process. Our low hydroxyl content quartz tubes (OH<5ppm) effectively reduce hydrogen defects in photovoltaic films and improve cell conversion efficiency by 0.3% -0.5%.

Optoelectronics and Lighting

Our large-diameter transparent quartz tube serves as the casing for high-intensity gas discharge lamps, and our anti UV attenuation formula increases the lamp's lifespan from the conventional 8000 hours to over 12000 hours. After a Japanese special lighting company adopted our 380mm quartz tube, the product's light attenuation rate decreased by 40%.

Chemical Engineering and Laboratory

In the field of observation windows and reactor liners in corrosive environments, our boric acid enhanced quartz tube has improved its resistance to hydrofluoric acid by three times, solving the long-term observation window atomization problem for a German chemical enterprise.

Product Advantage Analysis

1. Breakthrough in dimensional stability

Through a unique annealing process, we have solved the problem of elliptical deformation of large-diameter quartz tubes at high temperatures. The 600mm diameter product works continuously for 200 hours at 1100 ℃, with a diameter change rate of<0.07%, far below the industry average standard of 0.15%.

2. Purity control technology

Adopting a German imported electric arc melting furnace combined with multi-stage purification process, the content of key metal impurities (Na, K, Fe, Al) is controlled at ppb level, which is particularly suitable for semiconductor applications sensitive to metal pollution.

3. Optimization of thermal shock performance

The independently developed thermal stress relief technology has increased the thermal shock temperature difference of the product from the conventional 1100 ℃ to 1250 ℃. After being used by a fiber optic preform manufacturer, the cracking rate of quartz tubes has decreased from 3-5 times per month to zero.

4. Customization capability

Supporting the integrated manufacturing of irregular openings, flange connections, and special coatings (such as anti reflection and conductive films) to reduce customer secondary processing steps, a US laboratory equipment company has reduced assembly time by 65% through our pre processed quartz components.

The industry pain points we address

Problem 1: The contradiction between large size and high precision

Traditional quartz tubes have difficulty controlling wall thickness uniformity when their diameter exceeds 300mm. Our four axis synchronous control system ensures a wall thickness tolerance of ± 0.3mm for 600mm products, saving customers 15% -20% of material allowance costs.

Question 2: Performance degradation at high temperatures

Ordinary quartz tubes will undergo crystallization under long-term high temperatures. Our surface passivation treatment technology increases the crystallization initiation temperature from 1050 ℃ to 1200 ℃, extending the service life by 2-3 times.

Question 3: Delivery Time and Stable Quality

The conventional production cycle for large-diameter quartz tubes is as long as 8-12 weeks. We have shortened the delivery time for standard specifications below 400mm to 4-6 weeks through modular pre production and intelligent inventory systems, and emergency orders can be delivered in 2 weeks.

Customer Application Cases

Case A: Asia's leading photovoltaic enterprise

Challenge: Frequent replacement of quartz tubes in PECVD process (every 6-8 weeks) results in equipment downtime accounting for 15% of production time.

Solution: Adopt our low hydroxyl content quartz tube combined with inner surface nano coating

Result: The service life of the quartz tube has been extended to 24 weeks, the comprehensive utilization rate of the equipment has increased by 11%, and the annual maintenance cost has been saved by $280000.

Case B: European research institution nuclear fusion experimental device

Challenge: A super large quartz observation window with a diameter of 550mm and a length of 2.5m is required, which should be able to withstand a vacuum of 10 ⁻⁶ Pa and sudden cooling and heating cycles.

Solution: Customize a three-layer composite structure quartz tube with anti radiation material added to the middle layer

Result: The product successfully passed 2000 thermal cycle tests (room temperature -1000 ℃), and its vacuum retention performance exceeded the project requirements by 30%. It has been running stably for 18 months.

Case C: North American specialty glass manufacturer

Challenge: The observation window of the glass furnace needs to be replaced every 3 months due to sodium vapor corrosion, resulting in a 24-hour shutdown.

Solution: Provide corrosion-resistant quartz tubes with alumina surface modification

Result: The lifespan of the observation window has been extended to 9 months, reducing downtime by 144 hours annually and increasing production value by approximately $850000.

From semiconductors to new energy, from basic research to industrial mass production, the performance of large diameter quartz tubes as key process components directly affects the quality and production efficiency of the final product. We provide stable and reliable quartz solutions to global customers through continuous material innovation and process optimization.

What specific problems or challenges have you encountered while using your quartz tube? Is it due to insufficient thermal stability, purity issues, or customized requirements? Welcome to leave a message and communicate with us. Based on 20 years of industry experience, we will provide you with targeted suggestions.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

large diameter round quartz tube is a special industrial product made of high-purity fused silica, which is suitable for professional fields with strict requirements on diameter, thermal stability and chemical purity. The product adopts continuous melting process to ensure quality consistency in the full size range from 5mm to 600mm, with wall thickness uniformity controlled within ± 0.5mm and straightness deviation not exceeding 1mm/m.

Core technical parameters

-Diameter range: (supports non-standard customization)

-Purity grade: SiO ₂ content ≥ 99.95% -99.99%

-Thermal expansion coefficient: 5.5 × 10 ⁻⁷/℃ (0-1000 ℃)

-Thermal stability: maximum continuous use temperature of 1150 ℃, short-term temperature resistance of 1300 ℃

-Transmittance performance: Excellent transmittance in the ultraviolet to infrared band (special coating optional)

Key application areas

semiconductor manufacturing

The large-diameter quartz tube (300-600mm) serves as the core component of the diffusion furnace and LPCVD reaction chamber, providing a pollution-free and clean environment for silicon wafer processing. After a European semiconductor equipment manufacturer adopted our 450mm quartz tube, the cleaning cycle of the reaction chamber was extended from the original 4 weeks to 8 weeks, and the particle contamination rate was reduced by 62%.

photovoltaic industry

In solar cell manufacturing, quartz tubes with a diameter of 200-400mm are used for PECVD coating process. Our low hydroxyl content quartz tubes (OH<5ppm) effectively reduce hydrogen defects in photovoltaic films and improve cell conversion efficiency by 0.3% -0.5%.

Optoelectronics and Lighting

Our large-diameter transparent quartz tube serves as the casing for high-intensity gas discharge lamps, and our anti UV attenuation formula increases the lamp's lifespan from the conventional 8000 hours to over 12000 hours. After a Japanese special lighting company adopted our 380mm quartz tube, the product's light attenuation rate decreased by 40%.

Chemical Engineering and Laboratory

In the field of observation windows and reactor liners in corrosive environments, our boric acid enhanced quartz tube has improved its resistance to hydrofluoric acid by three times, solving the long-term observation window atomization problem for a German chemical enterprise.

Product Advantage Analysis

1. Breakthrough in dimensional stability

Through a unique annealing process, we have solved the problem of elliptical deformation of large-diameter quartz tubes at high temperatures. The 600mm diameter product works continuously for 200 hours at 1100 ℃, with a diameter change rate of<0.07%, far below the industry average standard of 0.15%.

2. Purity control technology

Adopting a German imported electric arc melting furnace combined with multi-stage purification process, the content of key metal impurities (Na, K, Fe, Al) is controlled at ppb level, which is particularly suitable for semiconductor applications sensitive to metal pollution.

3. Optimization of thermal shock performance

The independently developed thermal stress relief technology has increased the thermal shock temperature difference of the product from the conventional 1100 ℃ to 1250 ℃. After being used by a fiber optic preform manufacturer, the cracking rate of quartz tubes has decreased from 3-5 times per month to zero.

4. Customization capability

Supporting the integrated manufacturing of irregular openings, flange connections, and special coatings (such as anti reflection and conductive films) to reduce customer secondary processing steps, a US laboratory equipment company has reduced assembly time by 65% through our pre processed quartz components.

The industry pain points we address

Problem 1: The contradiction between large size and high precision

Traditional quartz tubes have difficulty controlling wall thickness uniformity when their diameter exceeds 300mm. Our four axis synchronous control system ensures a wall thickness tolerance of ± 0.3mm for 600mm products, saving customers 15% -20% of material allowance costs.

Question 2: Performance degradation at high temperatures

Ordinary quartz tubes will undergo crystallization under long-term high temperatures. Our surface passivation treatment technology increases the crystallization initiation temperature from 1050 ℃ to 1200 ℃, extending the service life by 2-3 times.

Question 3: Delivery Time and Stable Quality

The conventional production cycle for large-diameter quartz tubes is as long as 8-12 weeks. We have shortened the delivery time for standard specifications below 400mm to 4-6 weeks through modular pre production and intelligent inventory systems, and emergency orders can be delivered in 2 weeks.

Customer Application Cases

Case A: Asia's leading photovoltaic enterprise

Challenge: Frequent replacement of quartz tubes in PECVD process (every 6-8 weeks) results in equipment downtime accounting for 15% of production time.

Solution: Adopt our low hydroxyl content quartz tube combined with inner surface nano coating

Result: The service life of the quartz tube has been extended to 24 weeks, the comprehensive utilization rate of the equipment has increased by 11%, and the annual maintenance cost has been saved by $280000.

Case B: European research institution nuclear fusion experimental device

Challenge: A super large quartz observation window with a diameter of 550mm and a length of 2.5m is required, which should be able to withstand a vacuum of 10 ⁻⁶ Pa and sudden cooling and heating cycles.

Solution: Customize a three-layer composite structure quartz tube with anti radiation material added to the middle layer

Result: The product successfully passed 2000 thermal cycle tests (room temperature -1000 ℃), and its vacuum retention performance exceeded the project requirements by 30%. It has been running stably for 18 months.

Case C: North American specialty glass manufacturer

Challenge: The observation window of the glass furnace needs to be replaced every 3 months due to sodium vapor corrosion, resulting in a 24-hour shutdown.

Solution: Provide corrosion-resistant quartz tubes with alumina surface modification

Result: The lifespan of the observation window has been extended to 9 months, reducing downtime by 144 hours annually and increasing production value by approximately $850000.

From semiconductors to new energy, from basic research to industrial mass production, the performance of large diameter quartz tubes as key process components directly affects the quality and production efficiency of the final product. We provide stable and reliable quartz solutions to global customers through continuous material innovation and process optimization.

What specific problems or challenges have you encountered while using your quartz tube? Is it due to insufficient thermal stability, purity issues, or customized requirements? Welcome to leave a message and communicate with us. Based on 20 years of industry experience, we will provide you with targeted suggestions.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.