T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

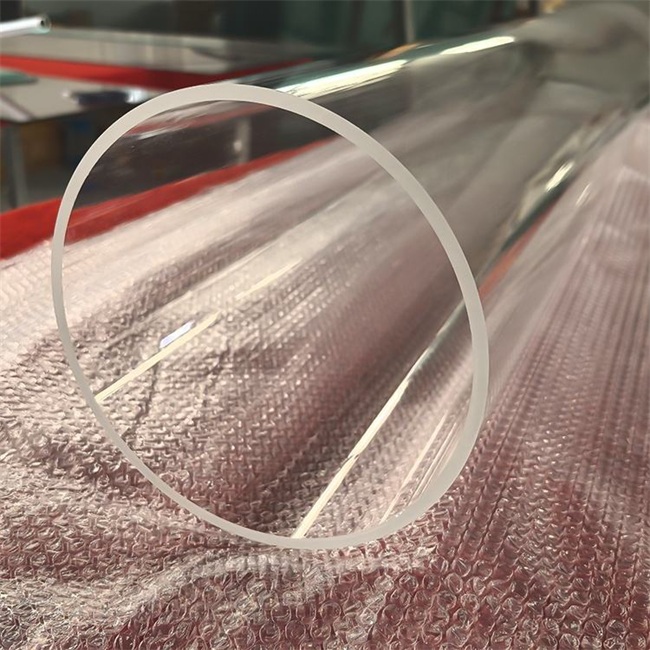

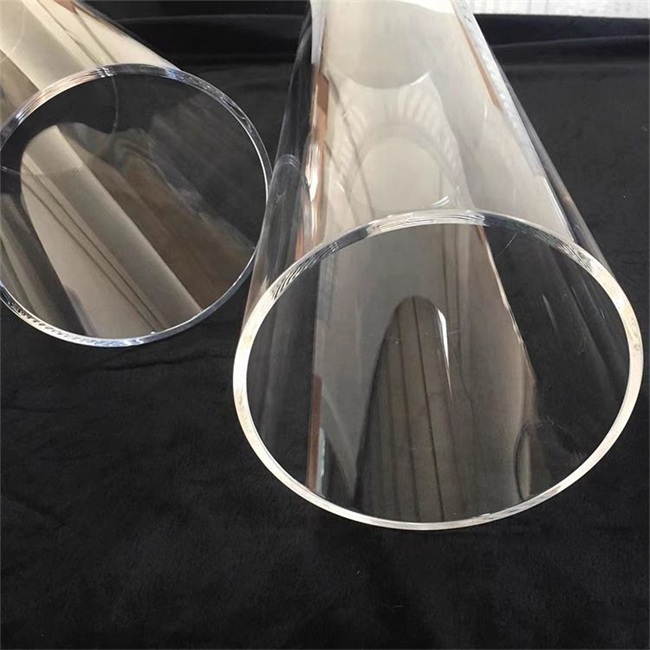

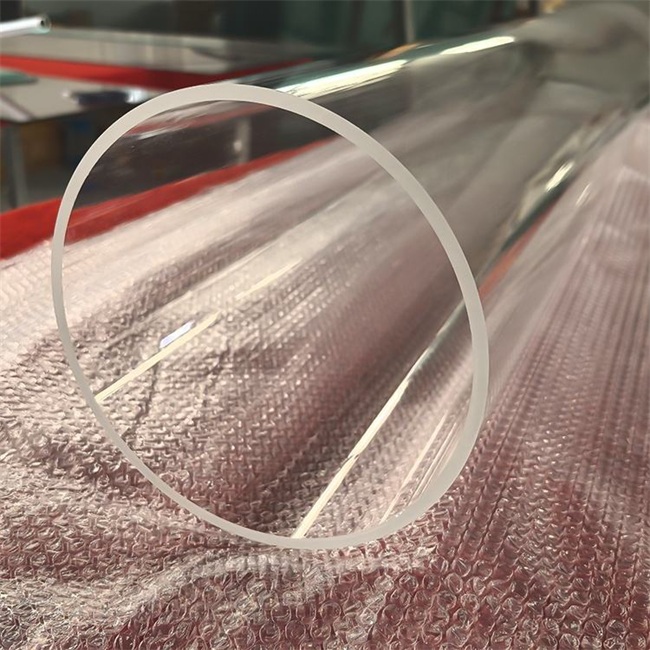

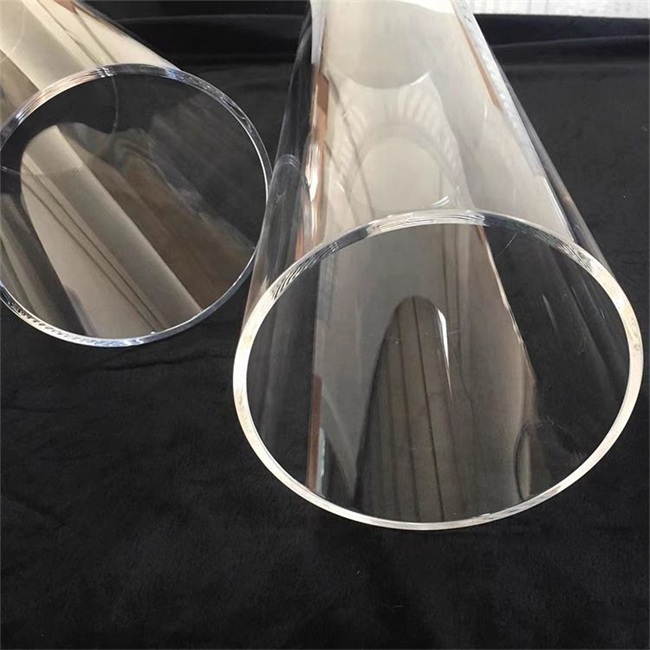

10-3500mm large diameter quartz tube

10-3500mm large diameter quartz tube, with a wide coverage range of diameters, high purity quartz material, excellent high temperature resistance, transparency, and chemical stability, suitable for high-temperature and precision manufacturing fields such as semiconductors, photovoltaics, lighting, etc.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

10-3500mm Large Diameter Quartz Tube: Customized Solution to Meet Global High End Industrial Needs

10-3500mm large diameter quartz tube, with a wide coverage range of diameters, high purity quartz material, excellent high temperature resistance, transparency, and chemical stability, suitable for high-temperature and precision manufacturing fields such as semiconductors, photovoltaics, lighting, etc.

As a professional quartz product manufacturer, we provide customized production services for large-diameter quartz tubes ranging from 10mm to 3500mm in diameter, covering full-size requirements from laboratory to industrial grade. The product is made of high-purity quartz raw material (SiO ₂ content ≥ 99.99%) and formed through precision temperature controlled melting process. It has excellent thermal stability, optical properties, and chemical inertness, and is suitable for high-end fields such as semiconductors, photovoltaics, optics, and chemical engineering.

Core product advantages

1. Ultra wide size range and precision manufacturing

-Diameter range: 10mm -3500mm (supports non-standard customization)

-Length customization: up to 6000mm in length, supporting segmented splicing

-Wall thickness control: ± 0.1mm accuracy, uniformity of over 95%

-Purity guarantee: The raw materials are tested by ICP-MS, and the impurity content is ≤ 50ppm

2. Excellent performance parameters

-High temperature resistance: softening point up to 1730 ℃, long-term use temperature of 1200 ℃

-Thermal expansion coefficient: 5.5 × 10 ⁻⁷/℃, excellent thermal shock resistance

-Optical transmittance: Transmittance in the ultraviolet to infrared wavelength range (170nm-3500nm)>92%

-Chemical stability: resistant to most acids, bases, and molten metals except hydrofluoric acid

3. Customized engineering capability

-Support secondary processing such as opening, sealing, flange connection, side arm, coating, etc

-Doping modification can be carried out according to customer needs (such as UV cutoff, infrared absorption)

-Provide value-added services such as mechanical strengthening treatment and surface polishing (Ra ≤ 0.4 μ m)

Key problems solved and application scenarios

1. Semiconductor and Photovoltaic Industry

Problem solved: Traditional quartz tubes have limited size and insufficient purity, leading to wafer contamination and poor thermal uniformity.

Application scenarios: diffusion furnace tube, CVD reaction tube, photovoltaic silicon wafer sintering carrier tube, polycrystalline silicon ingot furnace lining tube.

Customer case: A European photovoltaic equipment manufacturer used our Ø 1200mm × 3000mm large-diameter quartz tube as the lining tube for polycrystalline silicon ingot furnace. The product purity and thermal stability helped the customer increase the yield of silicon ingots by 8%.

2. Chemical Industry and High Temperature Treatment

Problem solved: Insufficient corrosion resistance and short lifespan of containers during metal melting and glass melting processes.

Application scenarios: High temperature corrosive medium transportation pipelines, metal melt observation windows, glass liquid stirring rods, electrolytic cell liners.

Customer case: A North American specialty metal smelter uses our Ø 800mm thick walled quartz tube as a molten metal observation channel, with thermal shock resistance that extends product life by three times compared to the original ceramic tube.

3. Optics and scientific research equipment

Problem solved: Insufficient transmittance and poor uniformity of large-sized optical components affect experimental accuracy.

Application scenarios: Large telescope mirror blanks, laser housings, spectrometer sample chambers, synchrotron radiation beamline pipelines.

Customer case: A laboratory in an Asian country customized a large Ø 2000mm × 100mm quartz mirror blank for space observation projects. The low expansion coefficient and high uniformity meet the imaging needs in extreme temperature environments.

4. Lighting and special equipment

Problem solved: Poor heat dissipation of high-power lighting fixtures and rapid attenuation of UV equipment transmittance.

Application scenarios: high-power halogen lamp cover, ultraviolet sterilization lamp tube, water treatment reactor window, large observation mirror.

Customer case: An Australian water treatment company uses Ø 1800mm quartz observation windows for large disinfection reaction tanks, with high UV transmittance increasing sterilization efficiency by 15%.

Specifications and Customization Services

Standard specification reference

-Diameter segmentation:

-Small tube: 10-200mm (laboratory grade)

-Medium sized pipe: 200-1200mm (industrial grade)

-Large pipe: 1200-3500mm (specially designed industrial grade)

-Conventional wall thickness: 1.5mm-30mm (designed according to diameter and pressure)

-Roundness tolerance: ≤ 0.5% (diameter ≤ 500mm); ≤ 1% (diameter>500mm)

Customer Application Case (Anonymous)

Case 1: German semiconductor equipment manufacturer

-Requirement: Quartz furnace tube with a diameter of 1800mm, requiring roundness deformation ≤ 0.8% at high temperatures

-Solution: Using quartz material doped with aluminum to enhance high-temperature rigidity; Increase wall thickness gradient design

-Result: The customer's production line yield increased by 3%, and the furnace tube life was extended to 1.5 times that of the original product

Case 2: American Photovoltaic Research Institute

-Requirement: 2800mm diameter transparent observation window for monitoring the growth process of silicon ingots

-Solution: Customized high uniformity optical grade quartz, double-sided polishing, transmittance>94%

-Result: Successfully achieved visualization of the ingot casting process, helping customers optimize temperature field design

Case 3: Japanese chemical companies

-Requirement: Corrosion resistant pipeline for conveying chlorosilane, diameter 800mm, length 5000mm

-Solution: Inner wall coating treatment+external reinforced sheath, tested through pressure cycling

-Result: Replacing the original stainless steel pipeline, the maintenance cycle has been extended from 6 months to 3 years

What problems can we solve?

-Size limitation: Provide ultra large diameter (>2000mm) products that are difficult to cover in the conventional market

-Strict working conditions: providing material solutions for high temperature, strong corrosion, and high-purity environments

-Cost pressure: direct manufacturer quotation to avoid multi-level agent markup

-Unstable delivery time: Our own production line and safety stock ensure on-time delivery

-Difficult to adapt to technology: support deep cooperation in drawing design, working condition simulation, etc

Contact us for customized solutions

If you are looking for a reliable supplier of large-diameter quartz tubes, or if existing suppliers cannot meet the size and performance requirements, please provide your operating parameters and design sketches. Our engineers will provide you with material selection recommendations, feasibility assessments, and preliminary quotations within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

10-3500mm Large Diameter Quartz Tube: Customized Solution to Meet Global High End Industrial Needs

10-3500mm large diameter quartz tube, with a wide coverage range of diameters, high purity quartz material, excellent high temperature resistance, transparency, and chemical stability, suitable for high-temperature and precision manufacturing fields such as semiconductors, photovoltaics, lighting, etc.

As a professional quartz product manufacturer, we provide customized production services for large-diameter quartz tubes ranging from 10mm to 3500mm in diameter, covering full-size requirements from laboratory to industrial grade. The product is made of high-purity quartz raw material (SiO ₂ content ≥ 99.99%) and formed through precision temperature controlled melting process. It has excellent thermal stability, optical properties, and chemical inertness, and is suitable for high-end fields such as semiconductors, photovoltaics, optics, and chemical engineering.

Core product advantages

1. Ultra wide size range and precision manufacturing

-Diameter range: 10mm -3500mm (supports non-standard customization)

-Length customization: up to 6000mm in length, supporting segmented splicing

-Wall thickness control: ± 0.1mm accuracy, uniformity of over 95%

-Purity guarantee: The raw materials are tested by ICP-MS, and the impurity content is ≤ 50ppm

2. Excellent performance parameters

-High temperature resistance: softening point up to 1730 ℃, long-term use temperature of 1200 ℃

-Thermal expansion coefficient: 5.5 × 10 ⁻⁷/℃, excellent thermal shock resistance

-Optical transmittance: Transmittance in the ultraviolet to infrared wavelength range (170nm-3500nm)>92%

-Chemical stability: resistant to most acids, bases, and molten metals except hydrofluoric acid

3. Customized engineering capability

-Support secondary processing such as opening, sealing, flange connection, side arm, coating, etc

-Doping modification can be carried out according to customer needs (such as UV cutoff, infrared absorption)

-Provide value-added services such as mechanical strengthening treatment and surface polishing (Ra ≤ 0.4 μ m)

Key problems solved and application scenarios

1. Semiconductor and Photovoltaic Industry

Problem solved: Traditional quartz tubes have limited size and insufficient purity, leading to wafer contamination and poor thermal uniformity.

Application scenarios: diffusion furnace tube, CVD reaction tube, photovoltaic silicon wafer sintering carrier tube, polycrystalline silicon ingot furnace lining tube.

Customer case: A European photovoltaic equipment manufacturer used our Ø 1200mm × 3000mm large-diameter quartz tube as the lining tube for polycrystalline silicon ingot furnace. The product purity and thermal stability helped the customer increase the yield of silicon ingots by 8%.

2. Chemical Industry and High Temperature Treatment

Problem solved: Insufficient corrosion resistance and short lifespan of containers during metal melting and glass melting processes.

Application scenarios: High temperature corrosive medium transportation pipelines, metal melt observation windows, glass liquid stirring rods, electrolytic cell liners.

Customer case: A North American specialty metal smelter uses our Ø 800mm thick walled quartz tube as a molten metal observation channel, with thermal shock resistance that extends product life by three times compared to the original ceramic tube.

3. Optics and scientific research equipment

Problem solved: Insufficient transmittance and poor uniformity of large-sized optical components affect experimental accuracy.

Application scenarios: Large telescope mirror blanks, laser housings, spectrometer sample chambers, synchrotron radiation beamline pipelines.

Customer case: A laboratory in an Asian country customized a large Ø 2000mm × 100mm quartz mirror blank for space observation projects. The low expansion coefficient and high uniformity meet the imaging needs in extreme temperature environments.

4. Lighting and special equipment

Problem solved: Poor heat dissipation of high-power lighting fixtures and rapid attenuation of UV equipment transmittance.

Application scenarios: high-power halogen lamp cover, ultraviolet sterilization lamp tube, water treatment reactor window, large observation mirror.

Customer case: An Australian water treatment company uses Ø 1800mm quartz observation windows for large disinfection reaction tanks, with high UV transmittance increasing sterilization efficiency by 15%.

Specifications and Customization Services

Standard specification reference

-Diameter segmentation:

-Small tube: 10-200mm (laboratory grade)

-Medium sized pipe: 200-1200mm (industrial grade)

-Large pipe: 1200-3500mm (specially designed industrial grade)

-Conventional wall thickness: 1.5mm-30mm (designed according to diameter and pressure)

-Roundness tolerance: ≤ 0.5% (diameter ≤ 500mm); ≤ 1% (diameter>500mm)

Customer Application Case (Anonymous)

Case 1: German semiconductor equipment manufacturer

-Requirement: Quartz furnace tube with a diameter of 1800mm, requiring roundness deformation ≤ 0.8% at high temperatures

-Solution: Using quartz material doped with aluminum to enhance high-temperature rigidity; Increase wall thickness gradient design

-Result: The customer's production line yield increased by 3%, and the furnace tube life was extended to 1.5 times that of the original product

Case 2: American Photovoltaic Research Institute

-Requirement: 2800mm diameter transparent observation window for monitoring the growth process of silicon ingots

-Solution: Customized high uniformity optical grade quartz, double-sided polishing, transmittance>94%

-Result: Successfully achieved visualization of the ingot casting process, helping customers optimize temperature field design

Case 3: Japanese chemical companies

-Requirement: Corrosion resistant pipeline for conveying chlorosilane, diameter 800mm, length 5000mm

-Solution: Inner wall coating treatment+external reinforced sheath, tested through pressure cycling

-Result: Replacing the original stainless steel pipeline, the maintenance cycle has been extended from 6 months to 3 years

What problems can we solve?

-Size limitation: Provide ultra large diameter (>2000mm) products that are difficult to cover in the conventional market

-Strict working conditions: providing material solutions for high temperature, strong corrosion, and high-purity environments

-Cost pressure: direct manufacturer quotation to avoid multi-level agent markup

-Unstable delivery time: Our own production line and safety stock ensure on-time delivery

-Difficult to adapt to technology: support deep cooperation in drawing design, working condition simulation, etc

Contact us for customized solutions

If you are looking for a reliable supplier of large-diameter quartz tubes, or if existing suppliers cannot meet the size and performance requirements, please provide your operating parameters and design sketches. Our engineers will provide you with material selection recommendations, feasibility assessments, and preliminary quotations within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.