T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

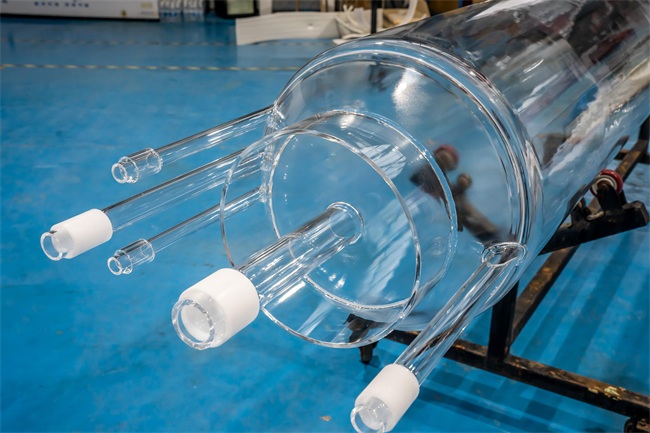

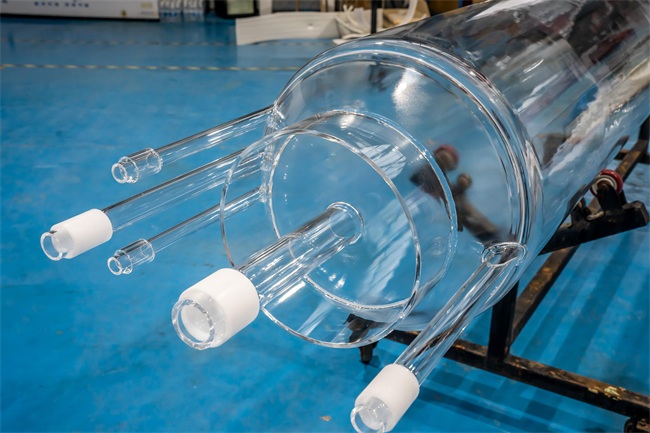

Large diameter quartz straight tube

The large diameter quartz straight tube is made of high-purity fused silica by precision processing, and has excellent thermal stability, chemical inertia and optical properties.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

The large diameter quartz straight tube is made of high-purity fused silica by precision processing, and has excellent thermal stability, chemical inertia and optical properties. Specially designed for industrial, scientific research, and high-end technology fields, it can meet the transmission, reaction, and observation needs in harsh environments.

Core product advantages

1. Excellent material performance

-High purity material: SiO ₂ content ≥ 99.99%, low bubbles, low impurities, ensuring chemical stability

-Extreme temperature resistance: softening point up to 1730 ℃, long-term use temperature of 1200 ℃, extremely low coefficient of thermal expansion

-Excellent optical performance: Excellent transmittance (UV to IR band), suitable for optical observation and transmission scenarios

2. Precision machining and specification advantages

-Large diameter range: The inner diameter can reach 50-500mm, and the wall thickness uniformity error is ≤± 0.5mm

-High dimensional accuracy: excellent straightness, flat end face, easy system integration and sealing connection

-Surface treatment options include polishing, sanding, flame treatment, and other processes to meet different needs.

Main application areas

industrial manufacturing

-Semiconductor manufacturing: diffusion furnace, CVD reaction tube, wafer carrier

-Photovoltaic industry: polycrystalline silicon ingot furnace, solar cell production equipment

-High temperature furnace tubes: heat treatment furnace, sintering furnace, experimental kiln

Research and Laboratory

-High end experimental equipment: optical experimental tube, vacuum system components, laser equipment

-Analytical instruments: spectrometer sample chamber, high temperature reaction observation window

-Customized research equipment: specially designed according to experimental needs

Special industries

-Chemical industry: Transport of corrosive media, high-temperature reaction vessels

-Optoelectronic industry: LED/MOCVD equipment, special lighting components

-Environmental Protection Engineering: High Temperature Smoke Observation Window, Monitoring System Components

The key problems we can solve

1. High temperature resistance problem

Replace ordinary glass and metal pipes to solve deformation, corrosion, and pollution problems in high-temperature environments

2. Chemical compatibility challenges

Maintain stability in environments with strong acids, strong alkalis, and corrosive media to extend the service life of equipment

3. Size and customization requirements

Provide non-standard large-diameter solutions, break through standard size limitations, and match special equipment requirements

4. System integration barriers

Accurate size control and multiple connection options reduce system integration difficulty and leakage risk

Why choose us?

Professional manufacturing capability

-18 years of professional production experience in quartz products, focusing on the foreign trade market

-Advanced CNC machining equipment and precision testing instruments ensure product consistency

-Continuous research and development improvement, serving customers in over 40 countries worldwide

Comprehensive customized services

1. Design support: Provide technical consultation and drawing optimization, jointly develop solutions

2. Size customization: Produce non-standard size products according to customer drawings or requirements

3. Process customization: customized services for special surface treatments, coatings, connection structures, etc

4. Small batch flexible production: accept trial orders and small to medium batch orders, respond quickly

Global Service Network

-Multi language technical support team (English, Spanish, German, etc.)

-Familiar with international packaging and logistics standards to ensure safe and timely delivery

Customer Application Case (Anonymous)

Case 1: European semiconductor equipment manufacturer

Requirement: A super large diameter quartz reaction tube for new CVD equipment, with an inner diameter of 400mm and a length of 2000mm, capable of withstanding long-term working temperatures of 1350 ℃, and with an ultra smooth inner wall treatment.

Solution: We use high-purity vapor deposition quartz material and control the uniformity of the tube body through a special molding process. The inner surface is precision polished with a roughness Ra ≤ 0.2 μ m.

Result: The product has passed the customer's 72 hour continuous high temperature test, with a particle contamination rate below the industry standard of 30%. It has been running stably for 18 months.

Case 2: American research laboratory

Requirement: A special optical experimental device requires a shaped quartz straight tube, including multiple lateral openings and flange connection structures, for synchrotron radiation experiments.

Solution: Based on the 3D model provided by the customer, segmented processing and high-temperature welding technology are adopted to ensure the dimensional accuracy and sealing of multiple connecting interfaces.

Result: The installation was successful in one go, and the light transmittance and vacuum sealing fully met the experimental requirements. The third phase of the project has been completed in cooperation.

Case Three: Asian Photovoltaic Enterprises

Requirement: Large quartz tubes for polycrystalline silicon ingot furnaces, with strong thermal shock resistance, ability to withstand rapid temperature cycles, and stable annual procurement volume.

Solution: Optimize material formula and annealing process, improve product thermal shock resistance, establish regular supply system and inventory management plan.

Result: The product's lifespan has been extended by 40% compared to the original supplier, and with the JIT delivery model, customer inventory costs have been reduced by 35%.

Get your customized solution

We are well aware that every application scenario has its uniqueness. Whether you need standard sized large-diameter quartz straight pipes or fully customized special designs, our engineering team can provide you with professional advice and solutions.

Immediate consultation: Please provide your specific needs, drawings or application scenario description, and we will provide you with a preliminary technical solution and quotation within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

The large diameter quartz straight tube is made of high-purity fused silica by precision processing, and has excellent thermal stability, chemical inertia and optical properties. Specially designed for industrial, scientific research, and high-end technology fields, it can meet the transmission, reaction, and observation needs in harsh environments.

Core product advantages

1. Excellent material performance

-High purity material: SiO ₂ content ≥ 99.99%, low bubbles, low impurities, ensuring chemical stability

-Extreme temperature resistance: softening point up to 1730 ℃, long-term use temperature of 1200 ℃, extremely low coefficient of thermal expansion

-Excellent optical performance: Excellent transmittance (UV to IR band), suitable for optical observation and transmission scenarios

2. Precision machining and specification advantages

-Large diameter range: The inner diameter can reach 50-500mm, and the wall thickness uniformity error is ≤± 0.5mm

-High dimensional accuracy: excellent straightness, flat end face, easy system integration and sealing connection

-Surface treatment options include polishing, sanding, flame treatment, and other processes to meet different needs.

Main application areas

industrial manufacturing

-Semiconductor manufacturing: diffusion furnace, CVD reaction tube, wafer carrier

-Photovoltaic industry: polycrystalline silicon ingot furnace, solar cell production equipment

-High temperature furnace tubes: heat treatment furnace, sintering furnace, experimental kiln

Research and Laboratory

-High end experimental equipment: optical experimental tube, vacuum system components, laser equipment

-Analytical instruments: spectrometer sample chamber, high temperature reaction observation window

-Customized research equipment: specially designed according to experimental needs

Special industries

-Chemical industry: Transport of corrosive media, high-temperature reaction vessels

-Optoelectronic industry: LED/MOCVD equipment, special lighting components

-Environmental Protection Engineering: High Temperature Smoke Observation Window, Monitoring System Components

The key problems we can solve

1. High temperature resistance problem

Replace ordinary glass and metal pipes to solve deformation, corrosion, and pollution problems in high-temperature environments

2. Chemical compatibility challenges

Maintain stability in environments with strong acids, strong alkalis, and corrosive media to extend the service life of equipment

3. Size and customization requirements

Provide non-standard large-diameter solutions, break through standard size limitations, and match special equipment requirements

4. System integration barriers

Accurate size control and multiple connection options reduce system integration difficulty and leakage risk

Why choose us?

Professional manufacturing capability

-18 years of professional production experience in quartz products, focusing on the foreign trade market

-Advanced CNC machining equipment and precision testing instruments ensure product consistency

-Continuous research and development improvement, serving customers in over 40 countries worldwide

Comprehensive customized services

1. Design support: Provide technical consultation and drawing optimization, jointly develop solutions

2. Size customization: Produce non-standard size products according to customer drawings or requirements

3. Process customization: customized services for special surface treatments, coatings, connection structures, etc

4. Small batch flexible production: accept trial orders and small to medium batch orders, respond quickly

Global Service Network

-Multi language technical support team (English, Spanish, German, etc.)

-Familiar with international packaging and logistics standards to ensure safe and timely delivery

Customer Application Case (Anonymous)

Case 1: European semiconductor equipment manufacturer

Requirement: A super large diameter quartz reaction tube for new CVD equipment, with an inner diameter of 400mm and a length of 2000mm, capable of withstanding long-term working temperatures of 1350 ℃, and with an ultra smooth inner wall treatment.

Solution: We use high-purity vapor deposition quartz material and control the uniformity of the tube body through a special molding process. The inner surface is precision polished with a roughness Ra ≤ 0.2 μ m.

Result: The product has passed the customer's 72 hour continuous high temperature test, with a particle contamination rate below the industry standard of 30%. It has been running stably for 18 months.

Case 2: American research laboratory

Requirement: A special optical experimental device requires a shaped quartz straight tube, including multiple lateral openings and flange connection structures, for synchrotron radiation experiments.

Solution: Based on the 3D model provided by the customer, segmented processing and high-temperature welding technology are adopted to ensure the dimensional accuracy and sealing of multiple connecting interfaces.

Result: The installation was successful in one go, and the light transmittance and vacuum sealing fully met the experimental requirements. The third phase of the project has been completed in cooperation.

Case Three: Asian Photovoltaic Enterprises

Requirement: Large quartz tubes for polycrystalline silicon ingot furnaces, with strong thermal shock resistance, ability to withstand rapid temperature cycles, and stable annual procurement volume.

Solution: Optimize material formula and annealing process, improve product thermal shock resistance, establish regular supply system and inventory management plan.

Result: The product's lifespan has been extended by 40% compared to the original supplier, and with the JIT delivery model, customer inventory costs have been reduced by 35%.

Get your customized solution

We are well aware that every application scenario has its uniqueness. Whether you need standard sized large-diameter quartz straight pipes or fully customized special designs, our engineering team can provide you with professional advice and solutions.

Immediate consultation: Please provide your specific needs, drawings or application scenario description, and we will provide you with a preliminary technical solution and quotation within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.