T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

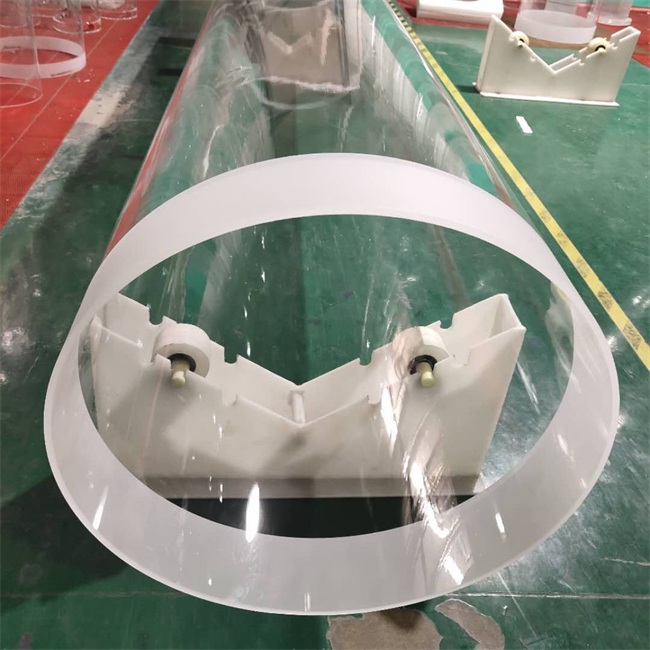

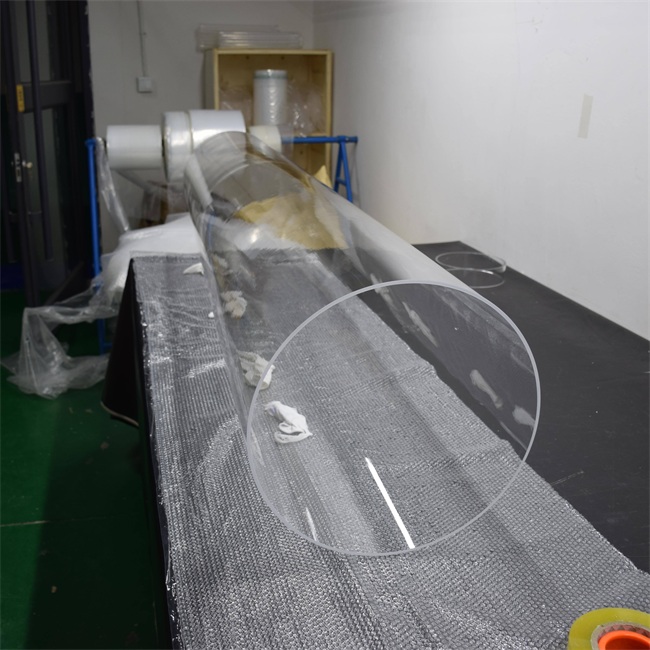

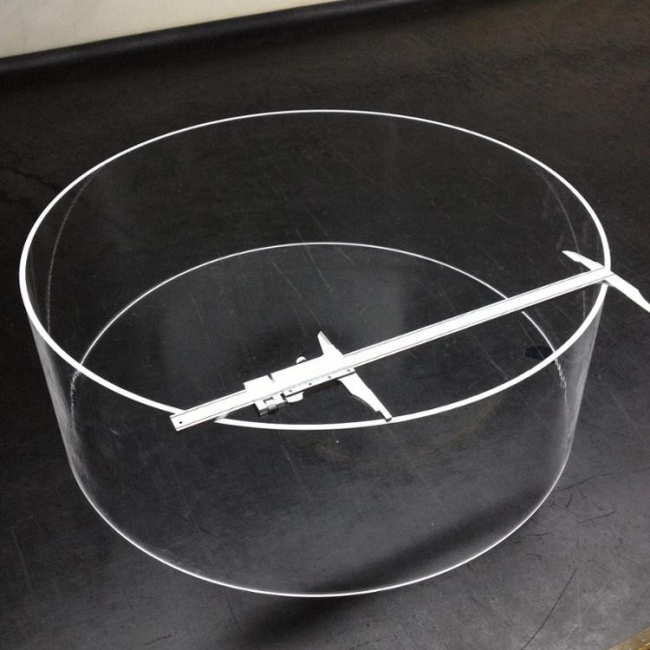

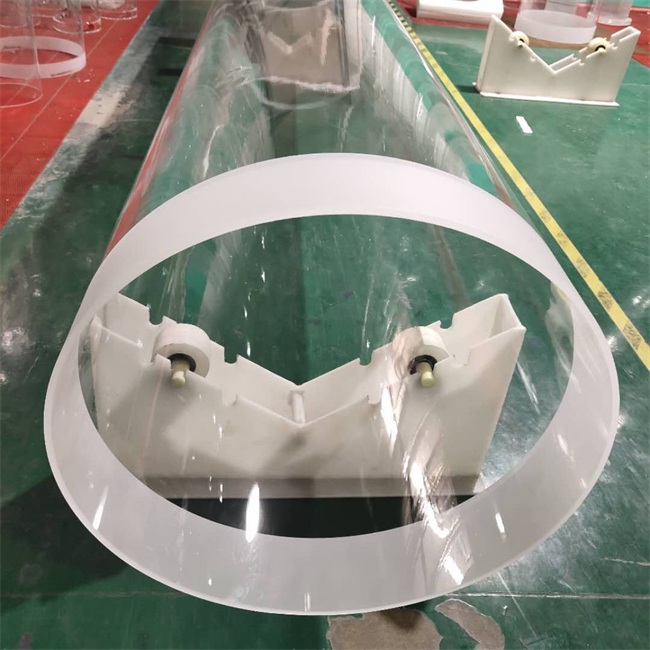

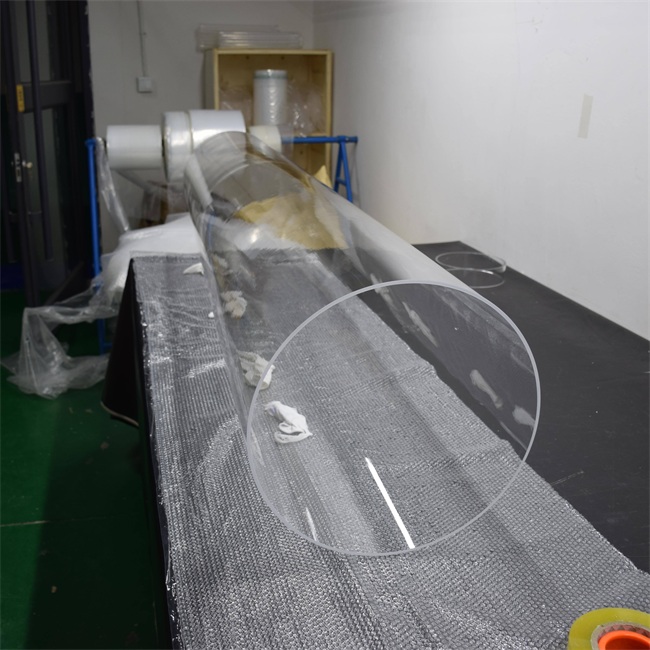

500-800mm large diameter quartz tube

500-800mm large diameter quartz tube is a super large specification quartz glass product, refined from high-purity quartz sand.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

500-800mm large diameter quartz tube is a super large specification quartz glass product, refined from high-purity quartz sand. Has excellent high temperature resistance, thermal stability, and outstanding light transmittance. Mainly used in the fields of semiconductor precision manufacturing, solar photovoltaics, and large-scale light sources, it is a key core material for modern high-tech industries.

The 500-800mm large-diameter quartz tube we professionally produce is made of high-purity fused silica material through advanced technology. The product has excellent thermal stability, chemical corrosion resistance, and optical performance, meeting the stringent requirements of high-end fields such as industry, scientific research, semiconductors, photovoltaics, etc. We offer a full range of customized sizes ranging from 500mm to 800mm in diameter, with wall thickness, length, end treatment, and more all available on demand, providing a one-stop quartz solution for global customers.

Core product advantages

1. Excellent material performance

-Purity of over 99.99%, SiO ₂ content ≥ 99.95%

-Extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), strong heat shock resistance

-Long term use temperature of 1200 ℃, short-term can reach 1450 ℃

-Excellent UV infrared transmittance performance (transmittance>90%)

2. Precision manufacturing process

-Formed by electric melting or gas refining method, with strict control of internal bubbles and impurities

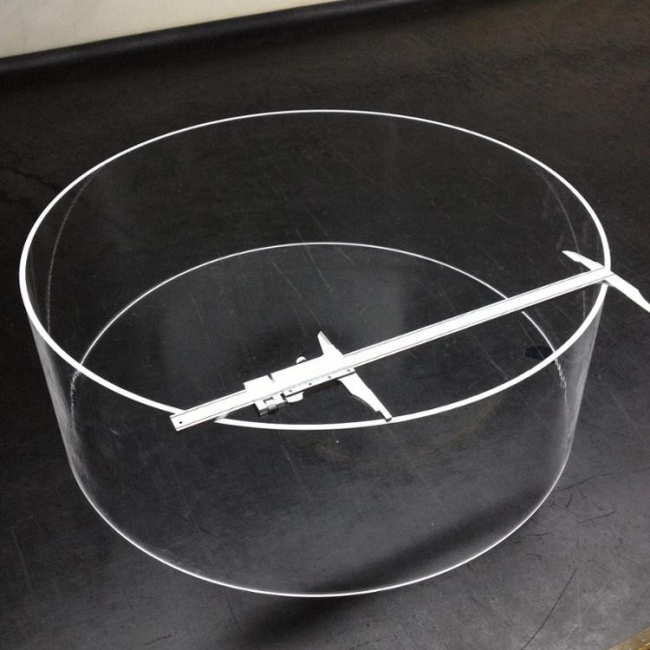

-High dimensional accuracy (diameter tolerance ± 0.5%, roundness deviation<0.3%)

-Surface smoothness can be customized (polished, frosted, flame treated)

-Can perform secondary processing such as cutting, drilling, sealing, flange connection, etc

3. Stable quality assurance

-Each batch of products undergoes bubble degree, stripe degree, and stress testing

-Compliant with international standards such as ASTM, ISO, JIS, etc

-Provide material reports and performance testing data

-Strong anti crystallization ability and significantly longer service life than the industry average

Specifications and Customization Services

Standard specification range:

-Diameter: 500mm, 550mm, 600mm, 650mm, 700mm, 750mm, 800mm

-Wall thickness: 5mm-25mm (optimized according to diameter and usage)

-Length: 500mm-3000mm (can be segmented and connected)

-End treatment: flat mouth, flanging, flange connection, head welding

Customization capability:

-Special dimensions and non-standard designs (supporting replication of drawings or samples)

-Selection of different purity levels (semiconductor grade, photovoltaic grade, industrial grade)

-Surface coating treatment (anti reflection, anti reflection, anti pollution coating)

-Integrated components (observation window, temperature measurement hole, pre fabricated air inlet)

-Balancing small-scale trial production and large-scale production (MOQ flexible)

Main application areas

1. Semiconductor and Photovoltaic Industry

-Diffusion furnace, oxidation furnace tube core

-Thermal insulation cover for polycrystalline silicon ingot furnace

-Photovoltaic cell sintering furnace tube

-Observation window for semiconductor process chamber

2. High temperature industrial equipment

-High temperature observation system for steel and glass industries

-Chemical reaction vessel liner

-Powder metallurgy sintering container

-Fiber preform manufacturing carrier

3. Scientific research and optics field

-Large scale experimental apparatus vacuum chamber

-Astronomical telescope mirror blank material

-Laser equipment optical cavity

-Synchrotron radiation beamline component

4. Environmental Protection and New Energy

-Smoke monitoring sampling tube

-Solar thermal power receiver

-Components of high-temperature exhaust gas treatment system

The key problems we can solve

1. Replace expensive imported products

To provide customers from Europe, America, Japan, and South Korea with products of equal quality but more competitive prices, and to shorten delivery times (4-6 weeks for regular orders and 2-3 weeks for urgent orders).

2. Break through technological bottlenecks

Solve technical problems encountered by customers in the production of oversized quartz products, such as poor uniformity, easy deformation, and insufficient temperature resistance. We use segmented molding and special annealing processes to ensure that 800mm diameter products still maintain excellent thermal stability.

3. Match complex system integration requirements

Provide pre assembled quartz components for equipment manufacturers to reduce on-site installation difficulty and risk of damage. For example, the 700mm quartz tube with flange connection port provided to a European photovoltaic equipment supplier reduced its equipment assembly time by 40%.

4. Coping with the challenges of harsh working conditions

Special formula materials can resist strong corrosive environments such as fluoride and chlorine gas, extending their service life in semiconductor etching equipment. Actual testing shows that our 650mm quartz tube has an extended lifespan of over 30% compared to conventional products in the same corrosive environment.

Application Case (Anonymous Display)

Case 1: North American semiconductor equipment manufacturer

-Requirement: 675mm diameter quartz chamber for the new generation of etching equipment, requiring high purity, low metal impurities, and resistance to fluorine based gas corrosion

-Solution: Customized semiconductor grade quartz tube with special anti-corrosion treatment, wall thickness of 18mm, length of 2200mm, integrated with 3 observation windows

-Result: The product has passed 2000 hours of continuous testing by the customer, with a metal impurity content of less than 1ppm. It has been purchased in bulk and applied to their G5 production line

Case 2: European Photovoltaic Research Institute

-Requirement: 800mm ultra large diameter quartz tube for new crystal silicon growth experiments, requiring extremely high temperature uniformity and transparency

-Solution: Segmented production using gas refining method, special annealing process to eliminate stress, optimized light transmittance to over 92%

-Result: The customer successfully completed the new silicon ingot growth experiment, and the quartz tube worked continuously for 500 hours at 1350 ℃ without any crystallization phenomenon

Case 3: Asian Fiber Prefabricated Rod Enterprises

-Requirement: 600mm quartz deposition tube, with ultra smooth inner wall, A-level bubble rating, and the ability to withstand rapid temperature rise and fall

-Solution: Customized inner wall precision polishing treatment, bubble control of ≤ 5 per cubic centimeter, optimized thermal shock performance

-Result: Customer yield increased by 15%, equipment maintenance cycle extended from 3 months to 8 months

Get your customized solution

Whether you need standard specifications or specially designed large-diameter quartz tubes, we can provide the technically feasible and economically reasonable best solution. Welcome to provide your specific parameters, application scenarios, and performance requirements. Our engineering team will provide you with detailed technical solutions and quotations within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

500-800mm large diameter quartz tube is a super large specification quartz glass product, refined from high-purity quartz sand. Has excellent high temperature resistance, thermal stability, and outstanding light transmittance. Mainly used in the fields of semiconductor precision manufacturing, solar photovoltaics, and large-scale light sources, it is a key core material for modern high-tech industries.

The 500-800mm large-diameter quartz tube we professionally produce is made of high-purity fused silica material through advanced technology. The product has excellent thermal stability, chemical corrosion resistance, and optical performance, meeting the stringent requirements of high-end fields such as industry, scientific research, semiconductors, photovoltaics, etc. We offer a full range of customized sizes ranging from 500mm to 800mm in diameter, with wall thickness, length, end treatment, and more all available on demand, providing a one-stop quartz solution for global customers.

Core product advantages

1. Excellent material performance

-Purity of over 99.99%, SiO ₂ content ≥ 99.95%

-Extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), strong heat shock resistance

-Long term use temperature of 1200 ℃, short-term can reach 1450 ℃

-Excellent UV infrared transmittance performance (transmittance>90%)

2. Precision manufacturing process

-Formed by electric melting or gas refining method, with strict control of internal bubbles and impurities

-High dimensional accuracy (diameter tolerance ± 0.5%, roundness deviation<0.3%)

-Surface smoothness can be customized (polished, frosted, flame treated)

-Can perform secondary processing such as cutting, drilling, sealing, flange connection, etc

3. Stable quality assurance

-Each batch of products undergoes bubble degree, stripe degree, and stress testing

-Compliant with international standards such as ASTM, ISO, JIS, etc

-Provide material reports and performance testing data

-Strong anti crystallization ability and significantly longer service life than the industry average

Specifications and Customization Services

Standard specification range:

-Diameter: 500mm, 550mm, 600mm, 650mm, 700mm, 750mm, 800mm

-Wall thickness: 5mm-25mm (optimized according to diameter and usage)

-Length: 500mm-3000mm (can be segmented and connected)

-End treatment: flat mouth, flanging, flange connection, head welding

Customization capability:

-Special dimensions and non-standard designs (supporting replication of drawings or samples)

-Selection of different purity levels (semiconductor grade, photovoltaic grade, industrial grade)

-Surface coating treatment (anti reflection, anti reflection, anti pollution coating)

-Integrated components (observation window, temperature measurement hole, pre fabricated air inlet)

-Balancing small-scale trial production and large-scale production (MOQ flexible)

Main application areas

1. Semiconductor and Photovoltaic Industry

-Diffusion furnace, oxidation furnace tube core

-Thermal insulation cover for polycrystalline silicon ingot furnace

-Photovoltaic cell sintering furnace tube

-Observation window for semiconductor process chamber

2. High temperature industrial equipment

-High temperature observation system for steel and glass industries

-Chemical reaction vessel liner

-Powder metallurgy sintering container

-Fiber preform manufacturing carrier

3. Scientific research and optics field

-Large scale experimental apparatus vacuum chamber

-Astronomical telescope mirror blank material

-Laser equipment optical cavity

-Synchrotron radiation beamline component

4. Environmental Protection and New Energy

-Smoke monitoring sampling tube

-Solar thermal power receiver

-Components of high-temperature exhaust gas treatment system

The key problems we can solve

1. Replace expensive imported products

To provide customers from Europe, America, Japan, and South Korea with products of equal quality but more competitive prices, and to shorten delivery times (4-6 weeks for regular orders and 2-3 weeks for urgent orders).

2. Break through technological bottlenecks

Solve technical problems encountered by customers in the production of oversized quartz products, such as poor uniformity, easy deformation, and insufficient temperature resistance. We use segmented molding and special annealing processes to ensure that 800mm diameter products still maintain excellent thermal stability.

3. Match complex system integration requirements

Provide pre assembled quartz components for equipment manufacturers to reduce on-site installation difficulty and risk of damage. For example, the 700mm quartz tube with flange connection port provided to a European photovoltaic equipment supplier reduced its equipment assembly time by 40%.

4. Coping with the challenges of harsh working conditions

Special formula materials can resist strong corrosive environments such as fluoride and chlorine gas, extending their service life in semiconductor etching equipment. Actual testing shows that our 650mm quartz tube has an extended lifespan of over 30% compared to conventional products in the same corrosive environment.

Application Case (Anonymous Display)

Case 1: North American semiconductor equipment manufacturer

-Requirement: 675mm diameter quartz chamber for the new generation of etching equipment, requiring high purity, low metal impurities, and resistance to fluorine based gas corrosion

-Solution: Customized semiconductor grade quartz tube with special anti-corrosion treatment, wall thickness of 18mm, length of 2200mm, integrated with 3 observation windows

-Result: The product has passed 2000 hours of continuous testing by the customer, with a metal impurity content of less than 1ppm. It has been purchased in bulk and applied to their G5 production line

Case 2: European Photovoltaic Research Institute

-Requirement: 800mm ultra large diameter quartz tube for new crystal silicon growth experiments, requiring extremely high temperature uniformity and transparency

-Solution: Segmented production using gas refining method, special annealing process to eliminate stress, optimized light transmittance to over 92%

-Result: The customer successfully completed the new silicon ingot growth experiment, and the quartz tube worked continuously for 500 hours at 1350 ℃ without any crystallization phenomenon

Case 3: Asian Fiber Prefabricated Rod Enterprises

-Requirement: 600mm quartz deposition tube, with ultra smooth inner wall, A-level bubble rating, and the ability to withstand rapid temperature rise and fall

-Solution: Customized inner wall precision polishing treatment, bubble control of ≤ 5 per cubic centimeter, optimized thermal shock performance

-Result: Customer yield increased by 15%, equipment maintenance cycle extended from 3 months to 8 months

Get your customized solution

Whether you need standard specifications or specially designed large-diameter quartz tubes, we can provide the technically feasible and economically reasonable best solution. Welcome to provide your specific parameters, application scenarios, and performance requirements. Our engineering team will provide you with detailed technical solutions and quotations within 24 hours.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.