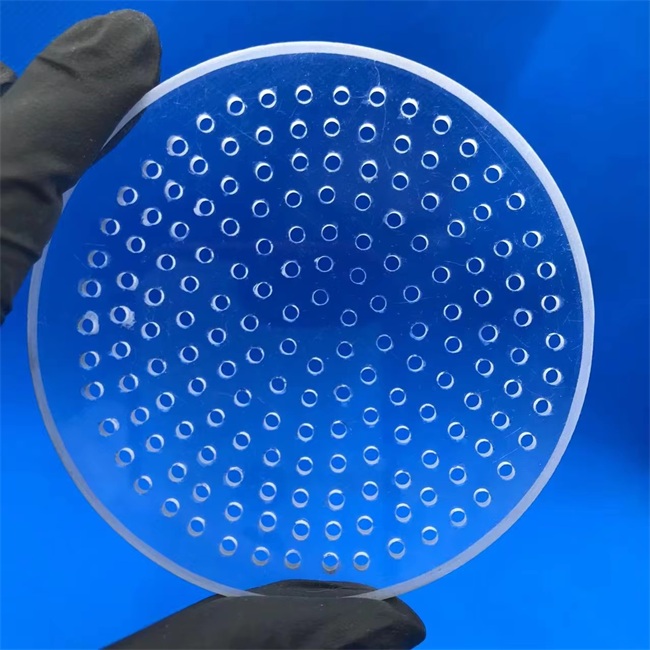

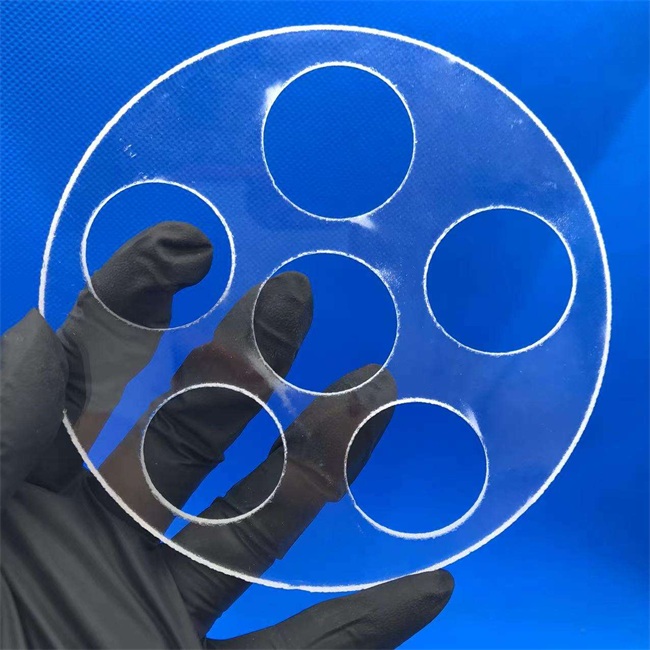

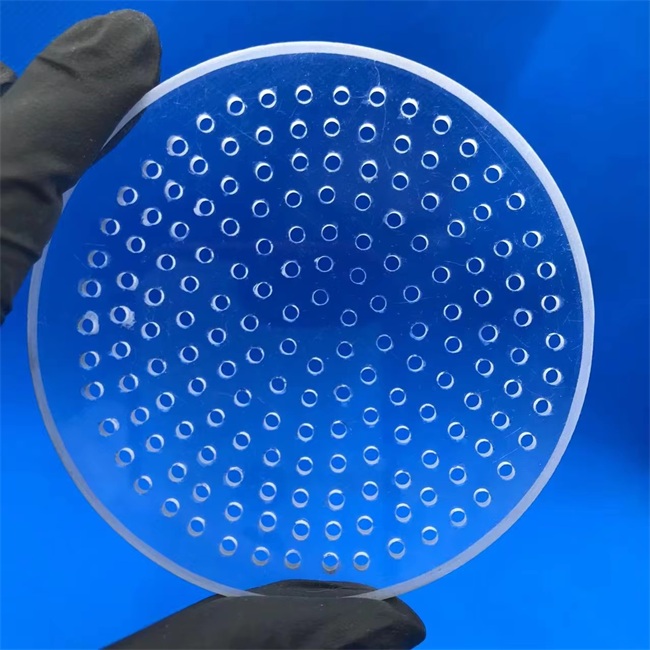

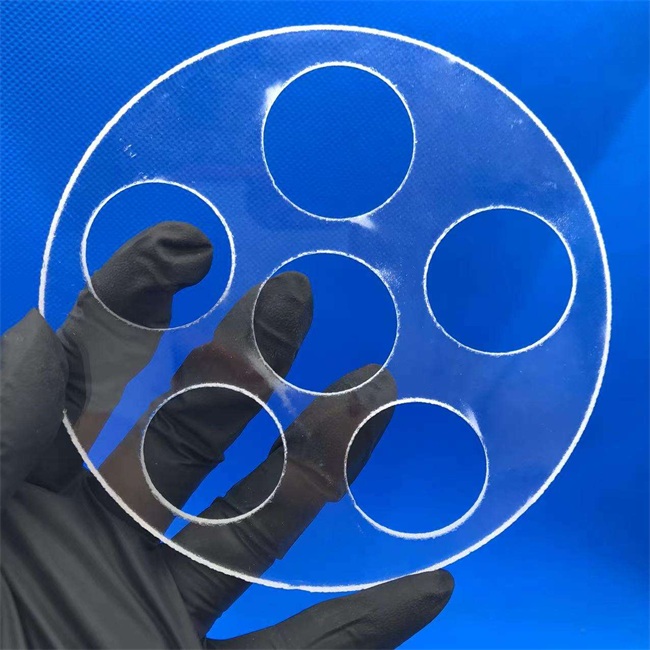

1-100mm diameter perforated quartz plate

Perforated quartz plate with a diameter of 1-100mm, made of high-purity quartz glass material, has characteristics such as high temperature resistance, corrosion resistance, and good transparency. Accurate size and controllable aperture, widely used in precision fields such as semiconductors, photovoltaics, laboratory instruments, etc.

Are you facing these challenges?

Q: Are you looking for perforated quartz plates that are heat-resistant, corrosion-resistant, and have precise dimensions?

Answer: Our customized perforated quartz plate can work stably in high temperature (up to 1100 ℃) and strong corrosive environments, with a hole diameter accuracy of ± 0.05mm, meeting the requirements of precision instruments and demanding industries.

Q: Are you troubled by the easy cracking and low yield of perforated edges on quartz plates?

Answer: We use laser precision cutting and edge strengthening technology to ensure smooth and crack free edges of the holes, with a yield rate of over 98%.

Q: Do you need flexible customization of aperture, hole type, and distribution pattern?

Answer: We support customization of any aperture within the diameter range of 1-100mm, and can achieve drilling designs for circular holes, square holes, irregular holes, and complex array patterns.

Q: Do you want to shorten the customization cycle and reduce overall costs?

Answer: We have a standardized pre-processing process and a fast response system, with a customized cycle that is 30% shorter than the industry average, providing a cost-effective one-stop solution.

Product Overview: Core Characteristics of Precision Punched Quartz Plates

Perforated quartz board is a functional board made of high-purity quartz material (SiO ₂ content ≥ 99.9%), which is precisely processed to form specific aperture, hole pattern, and hole array. The product has excellent thermal stability, chemical inertness, optical transparency, and electrical insulation, and is widely used in fields such as semiconductors, photovoltaics, optics, chemical engineering, and laboratory equipment.

Product advantages and technical parameters

1. Excellent material performance

-High temperature resistance: softening point up to 1730 ℃, long-term use temperature 1100 ℃

-Thermal stability: The coefficient of thermal expansion is as low as 5.5 × 10 ⁻⁷/℃, and the thermal shock resistance is excellent

-Chemical inertness: resistant to most acids, bases, and organic solvents except hydrofluoric acid and hot phosphoric acid

-Optical characteristics: Good transmittance in the ultraviolet to infrared wavelength range (170nm-2500nm)

-Electrical performance: high resistivity (>10 ⊃1;⁸Ω· cm at 20 ℃), excellent insulation material

2. Advantages of precision machining technology

-Aperture range: 1.0mm-100mm (supports customized consultation for micropores below 0.5mm)

-Processing accuracy: aperture tolerance ± 0.05mm, position accuracy ± 0.1mm

-Edge quality: Hole edge chipping<0.02mm, Ra surface roughness ≤ 0.8 μ m

-Thickness range: 0.5mm-50mm, supports integrated processing of thick and thin holes

-Diverse hole types: circular holes, square holes, slot holes, irregular holes, and porous arrays

3. Flexibility in customizing specifications

-Standard sizes: Available in standard sizes such as 100 × 100mm, 150 × 150mm, 200 × 200mm, etc

-Customized size: capable of processing up to 1000 × 600mm large panel materials

-Hole design: supports circular array, rectangular array, custom coordinates, and gradient aperture design

-Surface treatment: can provide polishing, sanding, coating (anti reflective, reflective, ITO, etc.) and other treatments

-Auxiliary processing: value-added services such as chamfering, slotting, edge polishing, logo etching, etc

Industry application scenarios

1. Semiconductor and Photovoltaic Industry

-Carrier trays and mask plates in wafer processing

-Precision substrate for photovoltaic cell printing screen

-Observation windows and baffles for diffusion furnaces and PECVD equipment

2. Optics and Optoelectronics

-Filter holder and aperture stop for optical instruments

-Cooling and heat dissipation plates for laser devices and beam shaping components

-Sample holder and window plate for spectral analysis instrument

3. Chemical and laboratory equipment

-Observation window and reactor lining in corrosive environments

-Insulation board and sample support board for high-temperature furnace

-Flow cell components and separation plates for analytical instruments

4. Application of emerging technologies

-Vacuum chamber window of quantum experimental device

-Substrate tray for MOCVD equipment

-Isolation template for 3D printed high-temperature components

Customer Application Case (Anonymous)

Case 1: German semiconductor equipment manufacturer

-Requirement: A precision circular hole quartz plate with a diameter of 76.2 ± 0.03mm is needed for wafer alignment system, requiring extremely low thermal expansion coefficient and UV light transmission

-Solution: UV grade fused silica material is used, the edge is polished after laser cutting, and the enhanced antireflection film is plated (transmissivity at 193nm is>99.5%)

-Result: The product has been continuously running in the customer's device for 18 months without any performance degradation, helping the customer improve alignment accuracy by 30%

Case 2: New Energy Laboratory in the United States

-Requirement: To develop a new type of fuel cell, a multi aperture gradient quartz diffusion plate is required, with apertures ranging from 2mm to 8mm in a hexagonal array distribution

-Solution: Design a 216 hole hexagonal array, use gradient aperture programming processing, and apply anti fog coating treatment on the surface

-Result: Gas diffusion uniformity has been improved to over 95%, helping customers increase their R&D efficiency by 40%

Case 3: Japan Optical Instrument Company

-Requirement: High precision optical aperture stop, 12 concentric circular holes, minimum aperture 0.8mm, required edge roughness Ra<0.4 μ m

-Solution: Adopting ultra precision laser processing combined with chemical polishing to achieve sub micron edge quality, with separate inspection reports for each hole attached

-Achievement: The product replaces the customer's original stainless steel components, improves optical performance, and reduces weight by 60%, winning the customer's annual excellent supplier award

Start your customized project

Whether you need standard specifications of perforated quartz panels or customized designs with special application requirements, our engineering team is always ready to provide technical support and solutions for you. Click to contact us for free sample evaluation, or submit your technical specifications for an instant quote. Let us use our 20 years of professional experience to provide reliable, precise, and high-performance quartz product solutions for your project.

Luverre Quartz manufactures and sells a wide range of high quality fused quartz glass, including fused quartz tubes, fused quartz plates, fused quartz rods, fused quartz windows, fused quartz crucibles, fused quartz boats, fused quartz flanges, fused quartz beakers, fused quartz glass instruments, and more. We can meet all kinds of customized requirements for fused quartz glass products.

For more information, please feel free to contact us.

Why choose us?

1.We are more experienced.

We have over 19 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

5. About 20 years of professional experience

-Focusing on the manufacturing of quartz products for a quarter century

-The average working experience of the technical team exceeds 10 years

6.Global Service Network

-Our products are exported to over 40 countries and regions including Europe, America, Japan, South Korea, and the Middle East

-Multi language technical support (English, German, French, Spanish, Russian, Japanese)