T: +86-518-85528012

E: nick@luverrequartz.com

E: nick@luverrequartz.com

1st floor Runlian industrial center No. 116 QuFeng Rd., Haizhou Economic and technological development zone Lianyungang City, Jiangsu Province, China 222062

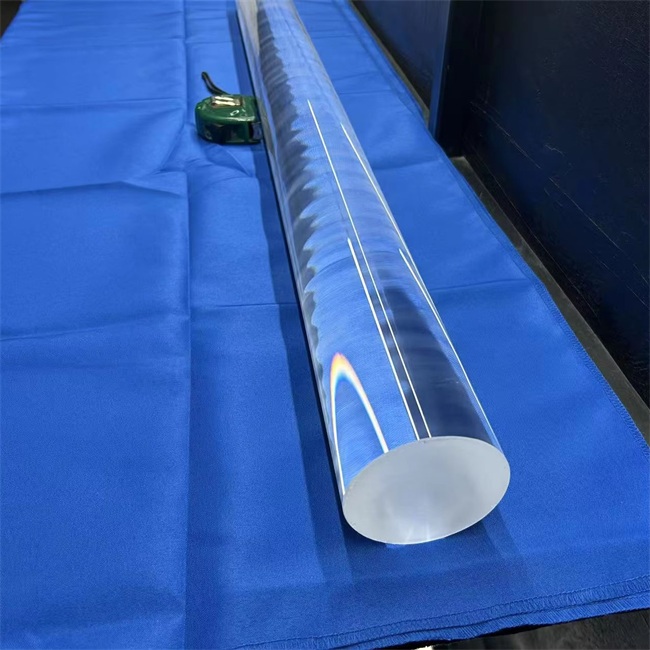

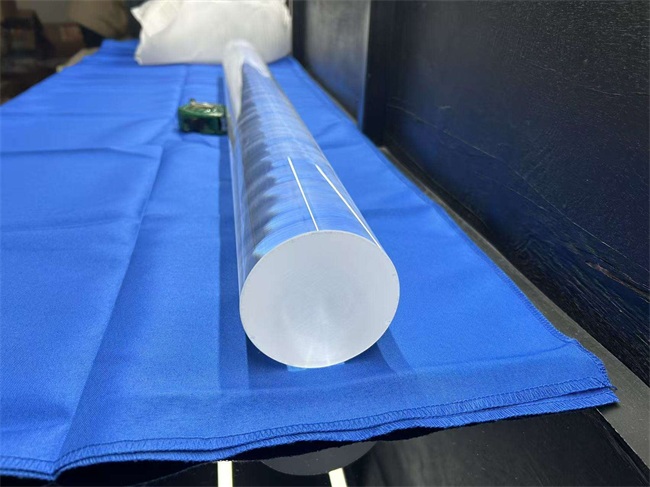

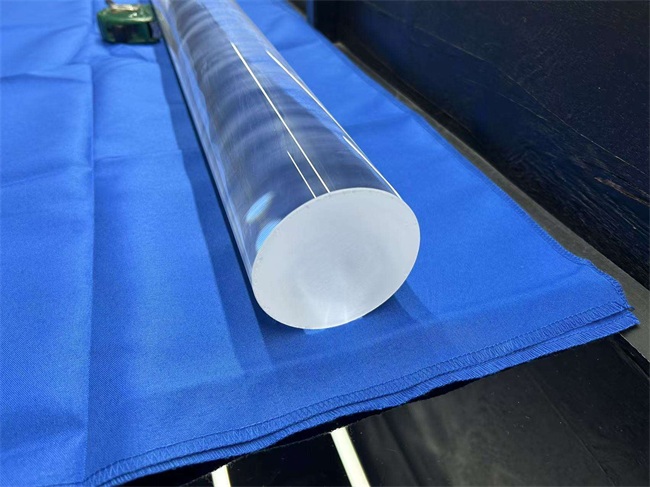

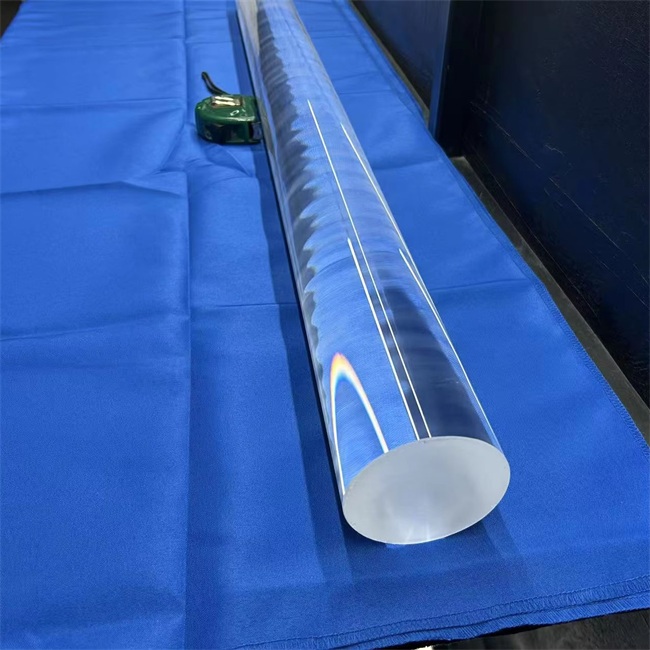

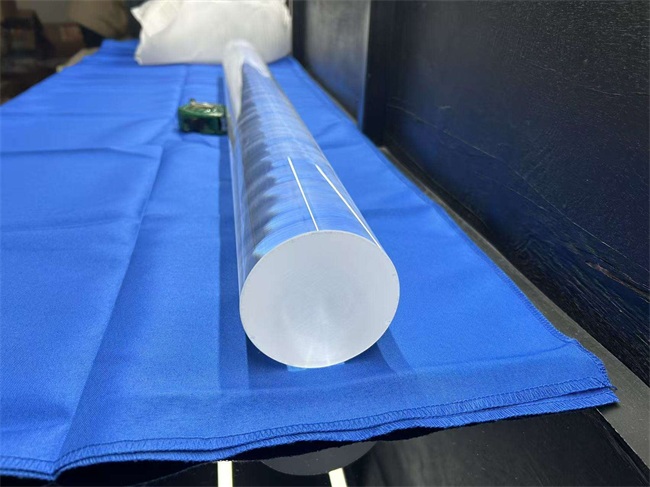

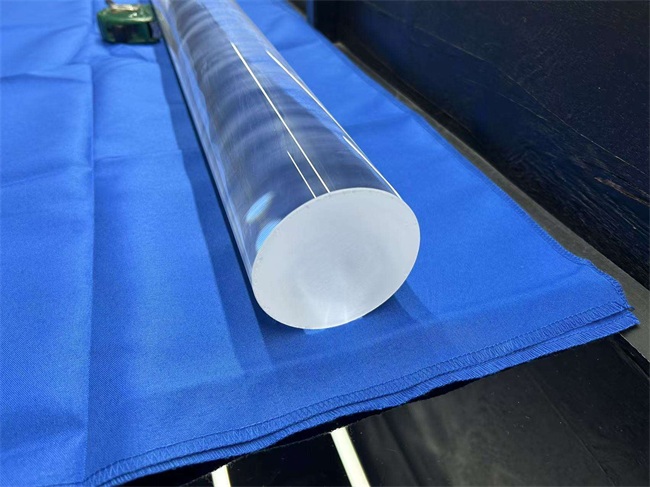

Welding supported quartz rod

Welded edge quartz rod is a high-performance industrial component made by precisely connecting multiple sections of quartz rod with specific angular structures through high-temperature welding technology.

LUVERRE quartz

99.99%

Inner with Vacuum PVC bag and then wrapped with air bubble film, outer with wooden box.

as per customer's requirement

| Availability: | |

|---|---|

Welded edge quartz rod is a high-performance industrial component made by precisely connecting multiple sections of quartz rod with specific angular structures through high-temperature welding technology. Using high-purity quartz material (SiO ₂ content ≥ 99.95%), it has excellent thermal stability, chemical inertness, and optical properties. It is designed for harsh industrial environments and widely used in semiconductor, optoelectronic, laboratory, and high-temperature process fields.

Core product advantages

1. Extraordinary material performance

-High temperature resistance: softening point up to 1730 ℃, long-term use temperature of 1200 ℃, instantaneous temperature resistance up to 1450 ℃

-Strong thermal stability: extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), excellent thermal shock resistance

-Chemical purity: High purity materials ensure no pollution and low precipitation, suitable for sensitive process environments

-Optical transmittance: Good transmittance in both ultraviolet and infrared bands (UV cutoff wavelength below 200nm)

2. Precision welding process

-Seamless welding technology: using hydrogen oxygen flame fusion welding process, the weld strength can reach more than 90% of the body material

-Dimensional accuracy control: diameter tolerance ± 0.1mm, angle deviation ≤ 0.5 °, straightness ≤ 0.1mm/300mm

-Structural integrity: no bubbles, no crystallization, no stress concentration points

3. Professional design and customization capabilities

-Multiple structural options available: right angled support, angled support, multi-directional support, irregular connections, and other configurations

-Wide size range: diameter 2-150mm, length 50-2000mm, supports customized non-standard sizes

-Surface treatment options: transparent surface, frosted treatment, flame polishing, etc

Main application areas

Semiconductor Manufacturing

-Bearing and supporting components for diffusion furnaces and CVD reaction furnaces

-Guidance and positioning components of wafer transfer system

-Sample support and isolation structure inside high-temperature furnace tube

Optoelectronics and Photovoltaic Industry

-Substrate support for photovoltaic coating equipment

-Optical path support and adjustment components inside the laser

-Reflection and Support Structure of Optical Heating System

Laboratory and research equipment

-Sample fixation and support of high-temperature experimental apparatus

-Spectrometer, sample chamber components of spectrometer

-Observation window and connecting components of vacuum system

Industrial high-temperature process

-Glass hot processing molds and support tools

-Ceramic sintering frame and isolation components

-Special material heat treatment tooling

The key problems we can solve

1. Reliability issues in extreme environments

Ordinary metal or ceramic supports are prone to deformation, corrosion, or contamination of the process environment in rapidly rising and falling temperatures, highly corrosive atmospheres, or high vacuum environments. Our welded ribbed quartz rods provide stable physical and chemical properties, ensuring process consistency.

2. High precision positioning requirements

Semiconductor and optical applications require extremely high precision in component positioning. Our products undergo precision machining and strict testing to ensure the accuracy of the support angle and positioning dimensions, reducing system debugging time.

3. Difficulties in customized matching

Standard components often cannot fully match specific equipment or process requirements. We provide full process customization services from design consulting to finished product delivery, ensuring perfect integration of components with customer systems.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

Customer Case (Anonymous)

Case 1: German semiconductor equipment manufacturer

Requirement: Quartz support structure for a new type of rapid annealing furnace, capable of withstanding rapid temperature rise and fall cycles of 50 ℃ per minute, requiring zero pollution and high precision.

Solution: Customized four-way support quartz rod bracket system, using special annealing process to eliminate thermal stress.

Result: The customer's equipment has been running continuously for 12 months without component failure, and the process pollution rate has been reduced by 70%. The product has been integrated into its standard equipment line.

Case 2: American Solar Energy Research Institute

Requirement: The multi angle quartz support system required for the new perovskite solar cell experimental device needs to meet both vacuum environment and ultraviolet irradiation conditions.

Solution: Design a modular edge support system, combined with special surface treatment to reduce light scattering.

Result: The reproducibility of experimental data has been improved by 40%, helping client research teams publish breakthrough results in top tier journals.

Case 3: Japan Optical Instrument Company

Requirement: High power laser internal optical path adjustment bracket, requiring precise multi angle fine-tuning within a limited space.

Solution: Miniature welding support system with a diameter of only 3mm, equipped with precision angle positioning structure.

Result: Laser calibration time has been reduced by 60%, and the long-term stability of the system meets the requirements of industrial grade applications.

Looking for a reliable supplier of welded ribbed quartz rods?

Our engineering team is always ready to analyze your specific application requirements and provide the best quartz solution. Please contact us through the website contact form or send your technical requirements directly to our business email. We will provide a preliminary plan and detailed quotation within 24 hours.

Share your specific needs and let us create precise matching quartz components for you!

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.

Welded edge quartz rod is a high-performance industrial component made by precisely connecting multiple sections of quartz rod with specific angular structures through high-temperature welding technology. Using high-purity quartz material (SiO ₂ content ≥ 99.95%), it has excellent thermal stability, chemical inertness, and optical properties. It is designed for harsh industrial environments and widely used in semiconductor, optoelectronic, laboratory, and high-temperature process fields.

Core product advantages

1. Extraordinary material performance

-High temperature resistance: softening point up to 1730 ℃, long-term use temperature of 1200 ℃, instantaneous temperature resistance up to 1450 ℃

-Strong thermal stability: extremely low coefficient of thermal expansion (5.5 × 10 ⁻⁷/℃), excellent thermal shock resistance

-Chemical purity: High purity materials ensure no pollution and low precipitation, suitable for sensitive process environments

-Optical transmittance: Good transmittance in both ultraviolet and infrared bands (UV cutoff wavelength below 200nm)

2. Precision welding process

-Seamless welding technology: using hydrogen oxygen flame fusion welding process, the weld strength can reach more than 90% of the body material

-Dimensional accuracy control: diameter tolerance ± 0.1mm, angle deviation ≤ 0.5 °, straightness ≤ 0.1mm/300mm

-Structural integrity: no bubbles, no crystallization, no stress concentration points

3. Professional design and customization capabilities

-Multiple structural options available: right angled support, angled support, multi-directional support, irregular connections, and other configurations

-Wide size range: diameter 2-150mm, length 50-2000mm, supports customized non-standard sizes

-Surface treatment options: transparent surface, frosted treatment, flame polishing, etc

Main application areas

Semiconductor Manufacturing

-Bearing and supporting components for diffusion furnaces and CVD reaction furnaces

-Guidance and positioning components of wafer transfer system

-Sample support and isolation structure inside high-temperature furnace tube

Optoelectronics and Photovoltaic Industry

-Substrate support for photovoltaic coating equipment

-Optical path support and adjustment components inside the laser

-Reflection and Support Structure of Optical Heating System

Laboratory and research equipment

-Sample fixation and support of high-temperature experimental apparatus

-Spectrometer, sample chamber components of spectrometer

-Observation window and connecting components of vacuum system

Industrial high-temperature process

-Glass hot processing molds and support tools

-Ceramic sintering frame and isolation components

-Special material heat treatment tooling

The key problems we can solve

1. Reliability issues in extreme environments

Ordinary metal or ceramic supports are prone to deformation, corrosion, or contamination of the process environment in rapidly rising and falling temperatures, highly corrosive atmospheres, or high vacuum environments. Our welded ribbed quartz rods provide stable physical and chemical properties, ensuring process consistency.

2. High precision positioning requirements

Semiconductor and optical applications require extremely high precision in component positioning. Our products undergo precision machining and strict testing to ensure the accuracy of the support angle and positioning dimensions, reducing system debugging time.

3. Difficulties in customized matching

Standard components often cannot fully match specific equipment or process requirements. We provide full process customization services from design consulting to finished product delivery, ensuring perfect integration of components with customer systems.

Why choose us?

1.We are more experienced.

We have over 18 years production experience of quartz items.

2.We are more efficient.

We reply customers’ requests within 24 hours and we have high efficient production, engineers and sales team.

3.Our quality is more guaranteed.

We control the quality from quartz lumps to quartz sand and then quartz products, we have better and stricter quality control than other manufactures.

4.We are able to produce more difficult quartz products.

We have large grinding platforms and precision etching machines which enable us to produce large sizes of quartz plates, tubes and high size precision quartz items.

Customer Case (Anonymous)

Case 1: German semiconductor equipment manufacturer

Requirement: Quartz support structure for a new type of rapid annealing furnace, capable of withstanding rapid temperature rise and fall cycles of 50 ℃ per minute, requiring zero pollution and high precision.

Solution: Customized four-way support quartz rod bracket system, using special annealing process to eliminate thermal stress.

Result: The customer's equipment has been running continuously for 12 months without component failure, and the process pollution rate has been reduced by 70%. The product has been integrated into its standard equipment line.

Case 2: American Solar Energy Research Institute

Requirement: The multi angle quartz support system required for the new perovskite solar cell experimental device needs to meet both vacuum environment and ultraviolet irradiation conditions.

Solution: Design a modular edge support system, combined with special surface treatment to reduce light scattering.

Result: The reproducibility of experimental data has been improved by 40%, helping client research teams publish breakthrough results in top tier journals.

Case 3: Japan Optical Instrument Company

Requirement: High power laser internal optical path adjustment bracket, requiring precise multi angle fine-tuning within a limited space.

Solution: Miniature welding support system with a diameter of only 3mm, equipped with precision angle positioning structure.

Result: Laser calibration time has been reduced by 60%, and the long-term stability of the system meets the requirements of industrial grade applications.

Looking for a reliable supplier of welded ribbed quartz rods?

Our engineering team is always ready to analyze your specific application requirements and provide the best quartz solution. Please contact us through the website contact form or send your technical requirements directly to our business email. We will provide a preliminary plan and detailed quotation within 24 hours.

Share your specific needs and let us create precise matching quartz components for you!

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products.